This post is also available in: 简体中文 (Chinese (Simplified))

Agglomeration papers will be presented by Primetals Technologies specialists at the ESTAD Congress covering the topics of sintering and pelletizing.

Numerical Simulation of the Sintering and the Pelletizing Processes

Principal author: Dr. Johann Reidetschläger

Paper number: 237

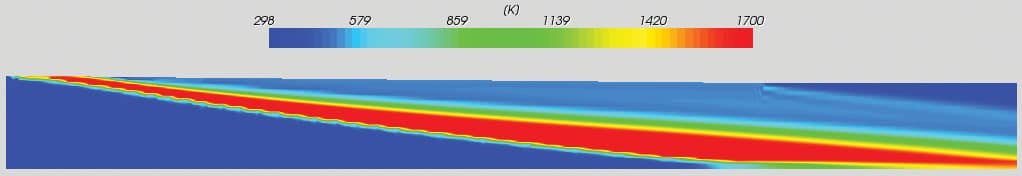

Changing the raw materials in an operating plant can significantly influence the sintering or pelletizing process. Adjusting all process parameters to regain stable and high productive operations takes considerable time and incurs production losses. Furthermore, changes in raw materials lead to variations in process gas flows and emission concentrations. Therefore, Primetals Technologies has developed two models for the numerical simulation of the sintering process and the pelletizing process. Among others, the models are based on the Ergun equation and include chemical reactions of the related processes. For plants already under operation, the simulations predict changes in the process parameters when raw materials are exchanged or when operational parameters are varied. In addition, the simulations provide valuable information for the design of greenfield plants and allow simulations for different plant configurations to be made. This paper describes the latest developments in the field of numerical simulations and shows how these sophisticated calculation tools can help producers master future challenges in agglomeration.

The Next Generation of Selective Waste Gas Recirculation Systems for Sinter Plants

Principal author: Marlene Mühlböck

Paper number: 242

Increasingly stringent global environmental regulations are forcing steel producers to continually improve the efficiency of sinter waste gas treatment. With the Selective Waste Gas Recirculation (SWGR) system from Primetals Technologies, lower production costs can be achieved and the size of downstream waste-gas-cleaning units can be reduced for investment savings. SWGR features the extraction and reuse of hot sinter offgas from selected wind boxes along the sinter strand, which contributes to improved energy efficiency and offgas treatment in the sintering process. The main emission components in sinter offgas are CO, CO₂, SOx, NOx and dioxins. The level of gaseous emissions depends on the physical and chemical properties of the sinter raw mix. Additionally, there are typical distribution profiles of the waste gas components emitted along the sinter strand. Therefore, the portion of sinter waste gas used for recirculation has a major impact on the final offgas treatment prior to the release to the environment through the stack. Different offgas-extraction and -recirculation strategies have therefore been developed. With the next generation of SWGR, Primetals Technologies can provide an energy-optimized, emission-optimized and environmentally friendly solution that meets customer requirements and local regulations. This paper demonstrates the latest developments in selective waste-gas recirculation, particularly the adjustable configuration of waste-gas recirculation schemes aligned to specific requirements.

Economic Waste-Heat Recovery for Different Sinter Cooler Types

Principal author: Gerald Strasser

Paper number: 262

In the energy-intensive sintering process, fine iron ore, recycled process materials, additives and fossil fuels are agglomerated to fulfill the requirements for high-performance blast furnace operations. The sintered material is discharged from the sinter strand in a temperature range between 500°C and 700°C and cooled down to less than 100°C on the sinter cooler. The sensible heat of the produced sinter, which amounts to about half of the total energy input, is normally lost to the environment at the sinter cooler. For a typical sinter plant with a capacity of 4.5 million t/a, more than 800,000 MWh/a of thermal energy – equivalent to the average annual heating energy requirements of some 40,000 central European households – is wasted as a result of cooling. To reduce energy costs, plant operators are increasingly looking at solutions to utilize this heat in an economic way. Waste-heat recovery systems have therefore been developed to meet the specific requirements of different sinter cooler types and on-site conditions. By means of specially designed cooler hoods, the bulk of the thermal energy in hot sinter can be extracted and efficiently used in a waste-heat boiler for steam generation. The steam can then be fed either to the local steam network for various local applications, or applied to produce electricity in a dedicated modular power block. By additional firing of low-calorific blast furnace gas in an external superheating system, the steam temperature and pressure can be further increased to meet local requirements. Technologies to improve the efficiency of heat-recovery during sinter cooling are discussed in this paper.

The Sinter Shaft Cooler: A Highly Energy-efficient Solution for Sinter Cooling

Principal author: Dr. Michaela Böberl

Paper number: 239

Primetals Technologies has developed a new sinter shaft cooler that is not only highly energy-efficient but is also much more environmentally friendly than conventional sinter coolers. The shaft cooler design allows the total heat capacity of the hot sinter to be utilized for heating the cooling air that moves in counterflow to the sinter during its descent through the shaft. With this solution, the temperature of the cooling air exiting the shaft can be maximized and more efficiently applied for the generation of steam and electricity in downstream process steps, or used for preheating and drying of materials or media used in a steelworks.

Compared to conventional sinter coolers, the sinter shaft cooler features lower specific investment and production costs, a reduced energy consumption for sinter cooling, a higher throughput, and reduced dust and other emissions due to a closed cooler shaft system. In this paper the features, benefits and challenges of the sinter shaft cooler are presented.

Circular Pelletizing Technology: A Revolutionary Solution

Principal author: Reinhard Redl

Paper number: 245

As the quality of raw materials worldwide is constantly decreasing, ultra-fine ore grades will dominate the future of iron- and steelmaking. The share of pellets in total iron production has increased steadily over the last ten years, and this trend is expected to intensify in the mid- and long term. In order to become independent of the steadily rising prices for pellets in the world market, steel producers are increasingly looking into the possibility to produce pellets directly at the steel plant site. By doing so, they can additionally achieve the exact chemical properties that are required for optimized production and improved product quality. Mine operators are also seeking an efficient, compact and feasible pelletizing technology to produce pellets within a smaller output range when this is required. Circular Pelletizing Technology (CPT) from Primetals Technologies is the next step in the evolution of highly efficient, ultra-compact pelletizing plants. Its footprint is significantly smaller than conventional plants and it offers a completely new level of flexibility in plant integration and pellet production. Iron and steel producers are thereby protected from the rising costs for pellet supply.