This post is also available in: 简体中文 (Chinese (Simplified))

Continuous Casting papers will be presented by Primetals Technologies specialists at the ESTAD Congress covering the topics of slab, billet and bloom casting in addition to automation, logistics and modernization solutions.

The Continuous Slab Caster in the Twenty-First Century

Principal author: Dr. Martin Hirschmanner

Paper number: 278

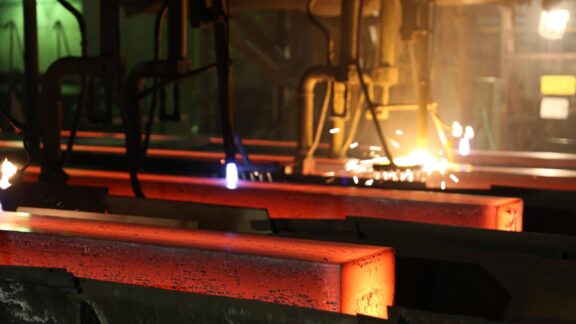

The first continuous casting machine built by VAI in the year 1968 already had several features that are still state of the art today. These include a straight mold, a continuous bending and unbending curve, and small, intermediately supported rollers for minimum bulging. It might be assumed that the mechanical development of the continuous slab caster was completed a long time ago. However, the opposite is true. Modern design methods make it possible to engineer a substantially improved caster that meets the ever-increasing demands of plant operators. In every critical performance parameter – including low maintenance costs, low operational costs and high-quality steel grades – improvements can still be achieved.

In recent years, the combination of mechanical equipment with hydraulic, electrical and automation systems has transformed the casting machine into a complex mechatronic system. The deep integration of all disciplines is essential for casting sophisticated steel grades with perfect process control, while still maintaining low operational costs. The ongoing fourth industrial revolution will also influence the design of continuous casting machines in a practical way that offers major advantages to plant operators. Several examples of mechanical features integrated in the caster mechatronic system are presented in this paper.

Innovation Highlights in Continuous Casting Automation

Principal author: Reinhold Leitner

Paper number: 201

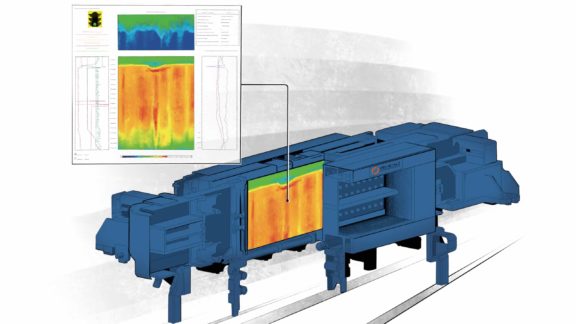

Sophisticated automation models are a prerequisite for state-of-the-art steelmaking. VAI has always been a driver of innovation in this area, especially by providing expert models for continuous casting machines. This capability is impressively demonstrated by recent advancements in automation solutions that include DynaPhase, Dynacs 3D and DynaGap. This state-of-the-art suite of dynamic secondary cooling and soft-reduction packages take into account thermodynamic effects such as shrinkage and phase transitions, and thereby significantly contribute to direct quality improvements during the solidification phase in the continuous casting process.

Speed Expert calculates an optimum casting speed for every casting situation, and additionally recommends a strand speed so that the point of final solidification is positioned at the end of a segment for optimum soft reduction. Nozzle Expert is a completely new model that detects clogged nozzles and broken hoses in secondary cooling systems. The first installations were highly successful and customers are pleased with improved steel quality and impressive reductions in maintenance costs. In the case of steel grade changes, the Intermix model precisely calculates the chemical properties of the mixed steel, thereby minimizing losses due to deviations from required specifications. Furthermore, a completely new human-machine interface (HMI) for the Level 2 automation system has been developed and successfully installed in recent projects. These solutions and operational results are described, and an outlook on future developments is presented.

Advanced Mold Technologies in Slab Casting

Principal author: Dr. Josef Watzinger

Paper number: 297

This paper deals with flexible mold equipment for the setup of single-, twin- or triple-strand casting machines and the associated technological packages to enable a fine adjustment of key process parameters. A newly developed and installed hydraulic divider for twin-slab casting allows fast and flexible width and taper changes to be made, even during casting. Cassette-type molds with flat and funnel-shaped copper plates at the wide sides are in operation. Specially designed narrow-face copper plates for specific functions are described. This includes plates with convex and concave shapes, chamfered or negative-chamfered copper plates, and specially combined narrow faces for rolling yield improvements. A new lateral strand-guide system is introduced, which features independent taper regulation of narrow-face copper plates and lateral foot rollers. Hydraulic-force control of the narrow side foot rolls enables optimum strand support that results in improved slab quality. The automation package DynaWidth ensures the correct narrow-side adjustments during cold and hot strand-width changes. The reliable S-mode empowers fast and large width changes at operational casting speeds, which allows extremely short tapered lengths to be achieved. Automatic narrow-face control is applied in order to keep well-balanced mold-heat extraction and consequently improved casting process stability.

Smart Modernization to Make Slab Casters Fit for Future Demands

Principal author: Josef Guttenbrunner

Paper number: 294

In the mid-1970s, VAI received its first order for the revamp of a slab caster, which marked the beginning of a long success story of caster upgrades. The goals during that era were to increase product quality and productivity, to meet the market requirements for low operational and maintenance costs, and to ensure high plant availability. These targets have not changed. Today, regular upgrading of continuous casting machines is becoming more and more important in order to fulfill these objectives at low investment costs. On the basis of the experience acquired from decades of upgrading slab casters, Primetals Technologies offers a complete portfolio of upgrading packages to meet the specific demands of producers. These packages can be easily integrated into existing casters and implemented within short production downtimes. The latest developments in caster upgrade concepts are presented. Solutions for upgrading casting platforms, machine heads, strand guides, secondary cooling systems and the caster maintenance area are described in detail. Examples of recently implemented upgrading projects are outlined, such as at Hüttenwerke Krupp Mannesmann in Duisburg, Germany, where a new hydraulic mold divider for the online-width adjustment of the twin slabs was installed.

It’s All about Temperature – Dry Casting for Optimum Surface Quality

Principal author: Paul Pennerstorfer

Paper number: 301

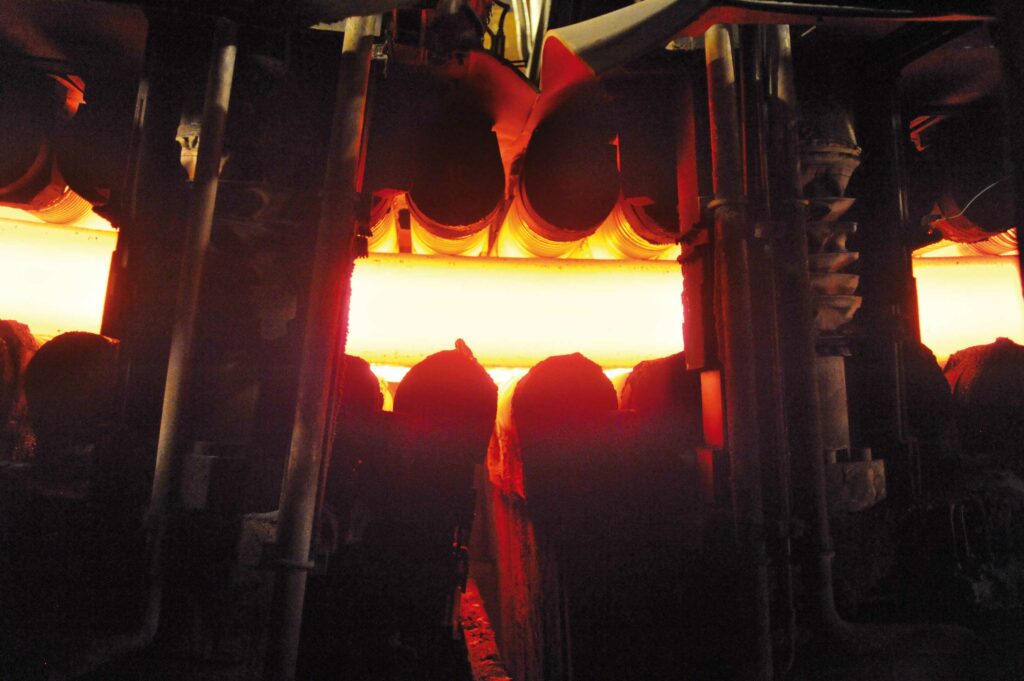

In the future, high-temperature casting, or so-called dry casting, will be used to a much greater extent for the production of surface-crack-sensitive steel grades, such as medium-micro-alloyed steel grades and advanced high-strength steels. To achieve this goal, the caster can operate with or without minimal external spray cooling in the bow and straightener area. The objective, however, is to keep the surface temperature above the ductility trough during unbending. To prepare for a higher demand for dry casting, Primetals Technologies has created the DynaTac package, which can be installed in both new and existing machines for high-temperature casting. The package covers everything from metallurgical process modeling to heat resistance and reliable strand-guide structures. This paper deals with the package itself and recent installations, especially on heavy-plate casters.

Next Steps in High-speed Billet Casting at Ege Çelik in Alliaga, Turkey

Principal author: Jeffrey Morton

Paper number: 285

Billet-casting trials were successfully executed at the Ege Çelik steelworks in Alliaga, Turkey, where a casting speed of 6.2 m/min. for 130 x 130 mm sections was achieved on the existing CCM4 machine. Additional investigations were subsequently carried out to stabilize the process in terms of steelmaking requirements and the casting machine setup. Unique measuring instrumentation was utilized to collect a vast array of data, including temperatures in the mold, actual negative strip time measured below the mold, and laser measurements of the actual casting speed. An evaluation of the acquired data helped to define the best machine characteristics for high-speed casting of long products and led to the development of the latest high-speed billet mold design from Primetals Technologies. The most recent results obtained from the high-speed trials at Ege Çelik are outlined and the novel features of the next generation of high-speed/high-quality molds are highlighted.

Latest Bloom Caster Solutions for Automotive Steel Grades

Principal author: Dr. Denijel Burzic

Paper number: 303

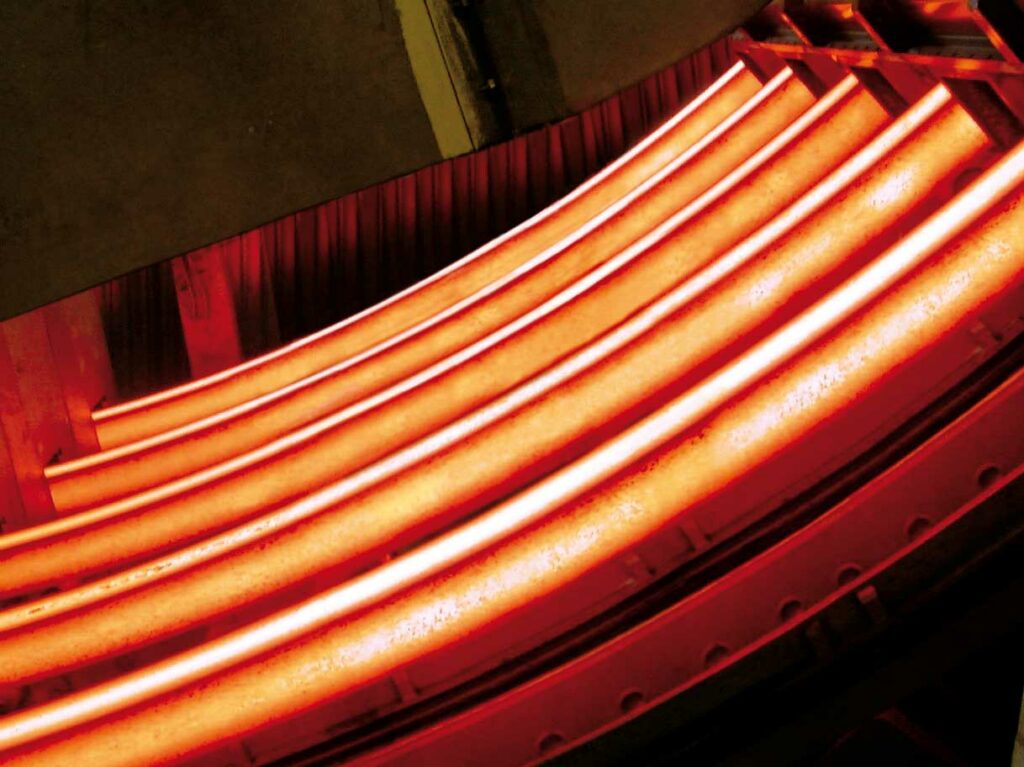

The latest solutions for continuous bloom casters are described in this presentation on the basis of an installed heavy-section, bow-type caster equipped with sophisticated technological packages. Bars and wires rolled from the blooms serve as a high-quality material for engine and gearbox parts. The caster features mold-level control and an instrumented mold for breakout prevention. In combination with air-mist spray cooling and internally cooled rollers in the strand-guidance system, DynaGap Soft Reduction and other technological packages ensure a uniformly high quality of the cast blooms. While still hot, the blooms are directly fed to the bar line. This saves reheating energy and improves operational safety because there is no need for bloom handling using cranes. For special steel grades, an inline bloom- quenching facility is planned.

Solutions for the Efficient Modernization of Billet and Bloom Continuous Casters

Principal author: Heinrich Thöne

Paper number: 276

For fast access to new or changing markets that cannot be served by a producer’s installed continuous casting machine (CCM), modification of an existing caster is the most cost-efficient way to meet demands. During the past decades, Primetals Technologies has successfully executed numerous revamping projects for billet, bloom and beam-blank casters. Modernization can involve the installation of advanced technological packages such as the DynaFlex hydraulic oscillator, DiaMold mold tube, or LevCon mold-level control to increase casting speed – and therefore throughput – with simultaneous improvements in casting reliability and product quality. Modernization may also be a comprehensive transformation into a high-end bloom or beam-blank caster within the footprint of the existing machine.

From the Caster to the Rolling Mill – Transport, Inspection, Conditioning and Treatment of Cast Products

Principal author: Philipp Wieser

Paper number: 287

The handling, storing and treatment of slabs, blooms, billets and beam blanks after casting as well as their preparation for the rolling process is a challenging procedure in a metallurgical plant. The hot strand leaving the casting machine – typically with a surface temperature in the range of 800°C to 1,100°C – must be cut, marked, inspected and, if necessary, conditioned. In the case of hot charging to the rolling mill, heat loss from the cast product must be minimized to reduce the energy consumption in the reheating furnace. For several steel grades, special ambient conditions (e.g., heat insulation) are required during the cooling process. In order to manage all of these requirements, this process must be thoroughly controlled and planned. The first step immediately after casting is product classification using a quality-prediction model based on the casting parameters and conditions (e.g., Quality Expert). A benefit of this powerful system is that it provides assistance regarding the decision whether conditioning (grinding or scarfing) is necessary or not with the goal to optimize yield. Automatic surface inspection of the hot products can further support conditioning decisions. The logistically complex process of handling and transporting cast products is ideally simulated using appropriate tools in order to avoid collisions and to calculate the cooling rate during the handling time. Multi-strand casters (even with 8 strands) in particular require extensive discharge cycle-time studies. Slab yards, cooling beds, quenching boxes and slow cooling boxes, all of which consume a lot of space in a steel mill, must be designed using thermal calculations. When quenching or slow cooling are required, additional calculations regarding precipitation and continuous cooling transformations must be considered. These and other logistical, thermal or quality-related aspects in the casting-rolling area of a steel mill are covered in this paper.