This post is also available in: 简体中文 (Chinese (Simplified))

In August 2013, a coupled pickling line and tandem cold-rolling mill (PLTCM) supplied by Primetals Technologies commenced operation at Ternium Mexico S.A. de C.V. (Ternium Mexico) in Monterrey. The facility, which has an annual rolling capacity of 1.5 million tons, is part of a major investment by Ternium to increase its production of advanced steel grades for the growing automotive market. Features of the different plant sections, products and benefits are described below.

The new PLTCM at Ternium Mexico has performed brilliantly since its start-up more than two years ago – which took place only 26 months after the contract signing. The advanced facility is designed to produce a wide range of rolled products that comprises thin-gauge strip with thicknesses down to 0.18 mm, high-tensile-strength automotive steels up to 980 MPa, exposed automotive steel grades and electrical steel (Table). The installed technologies from Primetals Technologies include jet-pickling tanks, Flying Width Change (FWC) side trimmer, and a 6-high Universal Crown Control Mill with work-roll shifting (UCMW). In combination with a sophisticated electrical control system supplied by Hitachi, the high-performance line produces strip that features extremely accurate thickness and flatness values as well as an excellent edge profile.

Coupling the pickling and cold-rolling steps results in a number of benefits for Ternium with regard to productivity, strip quality, yield and production costs. The elimination of strip threading and tailing out means a major increase in throughput capacity, a longer work-roll lifetime and fewer work-roll changes. Continuous operation minimizes strip head and tail ends and thus the frequency of off-gauge strip. These features result in a notable reduction in required maintenance and manpower costs.

Pickling section

The entry section for handling and feeding hot coils to the PLTCM is fully automated. This section includes dual payoff reels, a crop shear, a weighing scale, a laser beam welder and an entry looper. The laser welder in particular was selected for its ability to weld a wide range of steel grades, such as interstitial-free (IF) steel, high-tensile-strength steel and electrical steel. Surface quality monitoring takes place prior to pickling to detect any strip defects and thus avoid problems during line operation.

A tension-leveler-type scale breaker was installed for pre-descaling. Cassette-type roll changing was adopted to enable rapid roll change – even during strip threading. The patented jet-pickling process developed by Primetals Technologies was chosen for its high pickling performance and superior pickling results. Submerged jet nozzles are installed in each of the polypropylene pickling tanks, which are covered with a water-tight lid. This minimizes acid exposure to the atmosphere, evaporation and energy loss. Furthermore, automated acid concentration control with the use of a process model improves pickled strip quality and reduces excess acid consumption.

The strip is side-trimmed after pickling. Loopers are installed on both the entry and delivery sides of the side trimmer. Dual Center Position Control (CPC) in operation at the entry sides of both the side trimmer and tandem cold mill (TCM) ensures an accurate center positioning of incoming strip. Furthermore, immediately prior to the No. 1 mill stand, a three-roll bridle roll restrains the strip and feeds it securely into the roll bite.

Cold-rolling mill

The 5-stand 6-high UCMW is equipped with work-roll shifting to compensate for edge drop. The UCMW mill concept for shape control also includes work-roll and intermediate-roll bending, as well as intermediate roll shifting. Parallel ground crownless rolls are used for work, intermediate and backup rolls during most rolling operations, including the rolling of high-strength steels. Work rolls with a modified shape at the strip edges are used to roll electrical steels. Normally, electrical steels require a very flat strip shape profile, as they are used in laminated blocks and clearance between each layer should be as small as possible to ensure good magnetic characteristics. The amount of edge drop in cold rolling can be reduced by dynamically shifting the roll position during rolling and by adjusting the gap between the work rolls. This leads to an improved yield.

Primetals Technologies offers two types of UCMW mills: one with short stroke [UCMW(S)] and the other with long stroke [UCMW(L)]. The actual application depends on the product mix. At Ternium Mexico, the UCMW(S) – with a shifting stroke of around 150 mm – was installed with consideration to the low volume of electrical steels produced and the need to roll wider materials such as automotive steel. At the mill exit, the section of strip that contains the weld made at the entry side of the pickling line is cut out by a rotary shear.

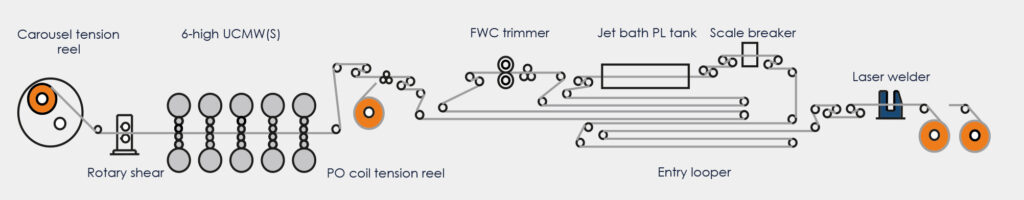

A carousel-type reel is used for the tension reel. Since the position to start winding is always the same near the TCM, the carousel reel has the advantage of reducing strip defects and strip walking compared to using two tension reels. Coils are automatically weighed, banded and labeled during the coil cycle. The coil is inspected on an offline inspection table connected to the line by means of an inspection coil car and inspection payoff reel. Figure 1 shows a general layout of the coupled pickling line and tandem cold-rolling mill.

Mill control

Automatic gauge control (AGC) of strip consists of conventional feed forward AGC (FF-AGC), roll position control AGC (BISRA-AGC) based on a gauge meter formula, and also monitor-AGC. In addition to these, mass flow AGC and an AGC system based on decoupling control are included. Mass flow AGC measures the actual running speed of the strip with laser speed meters installed at the exit of stands No. 1 through No. 5 and feeds back the measured data for gauge control. This method helps increase accuracy of gauge control, particularly in the acceleration and deceleration phases. Decoupling control is a method to suppress interference between inter-stand tension variations resulting from strip gauge and rolling-force variations. This control improves the strip gauge accuracy in the normal rolling phase. Furthermore, unlike the conventional control process that employs an initial setup using the data obtained from previously rolled strip, the Hitachi system applies a dynamic schedule change using data obtained from current rolling. This control can dynamically adjust the setting of thickness for each stand delivery. As a result, load balance between each stand is optimized. This greatly contributes to the improvement of operating stability and high efficiency of the facilities.

Flying gauge change (FGC) must be performed accurately and quickly. This is especially true for materials rolled at low speeds where it is hard to get precise gauge control and for which gauge precision is considered indispensable to obtain a high yield. Variation in rolling force following a flying gauge change considerably affects the control of strip shape. The UCM mill addresses this problem with high lateral rigidity compared to a 4-high mill or other types of 6-high mills. Strip-crown deformation caused by fluctuations in rolling force due to flying gauge change is thus minimized. A new automatic response adjustment system for the hydraulic roll gap controller was included. It consists of an automatic monitoring function that performs measurements for a number of preset control gains, and an automatic tuning function that searches for applicable control gain. Because this system is connected to the mill controller, it can start measuring at a specific time and obtain actual rolling data.

Customer feedback

Following more than two years of operational experience with the PLTCM, Ternium Mexico has particularly praised the robustness of the line to meet changing market requirements. This robustness can be attributed to several factors. For one, the highly automated production line minimizes manual intervention. Another key factor is the server in charge of calculating the setup processes and its ability to rapidly process a great amount of information in a very short time by using predefined values, mathematical modeling, statistical analyses and coil information provided by Ternium. The interface between Ternium tracking and Hitachi tracking is also successful due to the clear communication structure and traceability. Finally, the communication protocol inside the Hitachi system network is very stable and reliably delivers each preset value in time for all equipment in the PLTCM. In the end, all of these factors lead to high-quality products with precise thickness and flatness, excellent edge profiles and high productivity.