Minimum Quantity Lubrication (MQL) is Primetals Technologies’ next generation roll-gap lubrication system for cold-rolling mills, applying neat rolling oil atomized with air directly onto the surfaces of the work rolls. This is especially relevant in light of recent trends toward increasing production of advanced high-strength steel grades (AHSS) for the automotive industries or silicon steels for electrical appliances.

MQL allows for intelligent control of the oil-film thickness depending on the rolling process. Based on actual process and product parameters, the digital solution can determine and control the optimum amount of oil to maximize rolling efficiency and secure rolling stability (intelligent forward-slip control). MQL not only ensures optimum product-specific lubrication, but the effortless and rapid change of lubrication settings offers a much higher degree of flexibility than has been previously possible with classical emulsion systems. Comprehensive tests at three different European steel producers proved the industry strength, and also showed conclusively that MQL permits the application of considerably lower rolling forces and motor torques, as it maximizes the level of oil concentration in the roll bite. These savings can be converted into more reduction or a wider strip. Another major advantage of the system is better strip-surface cleanliness, which is achieved via improved lubrication leading to less strip wear and hence less iron fines on the strip surface after cold rolling.

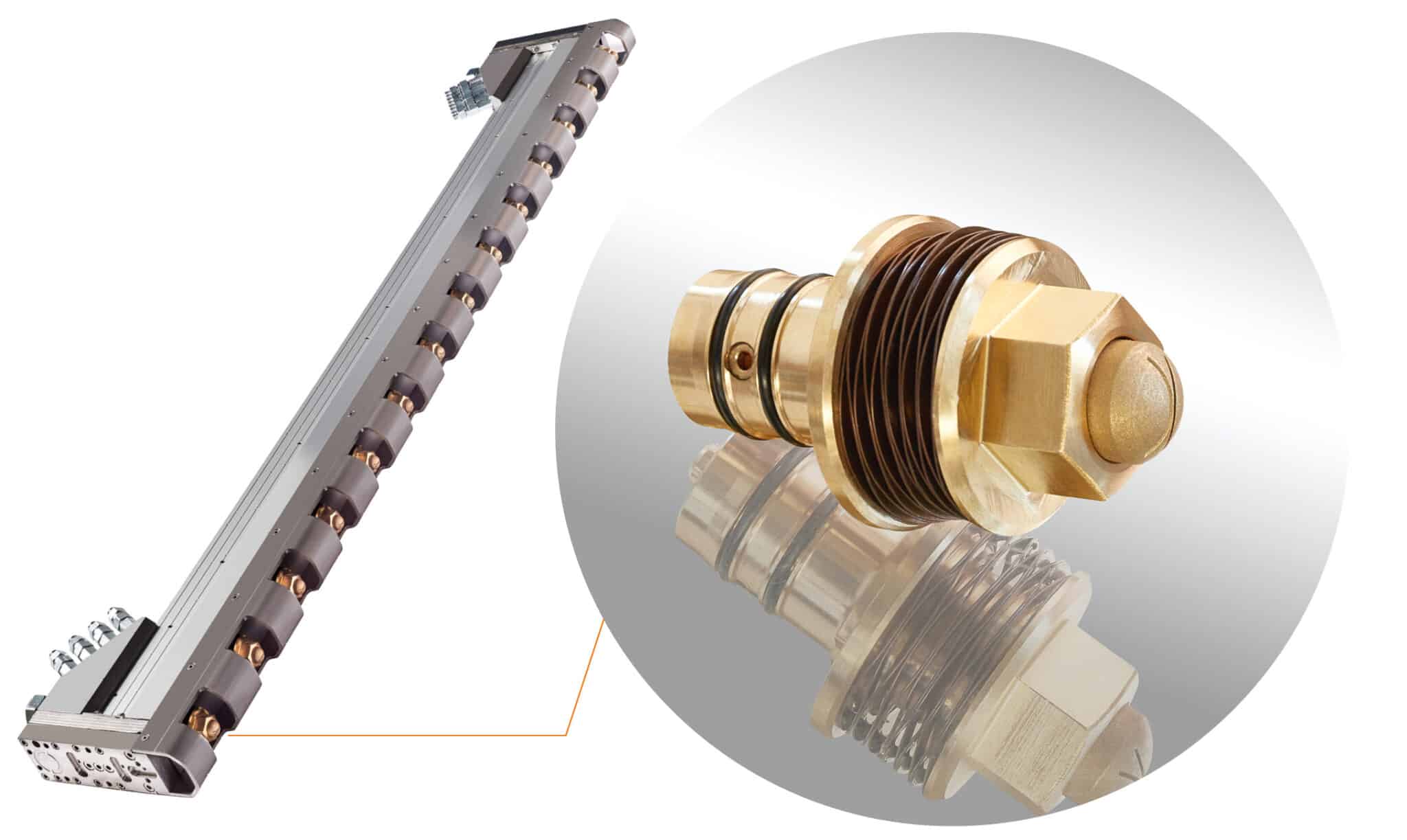

MQL is a pre-tested technology package now available to customers and consists of spray bars with quick-change nozzles (as illustrated above), an oil-supply unit, and a process unit with a defined interface to the mill automation system. The system can be easily installed on existing mills either as an additional lubrication system, or to replace an existing emulsion recirculation or direct application system.

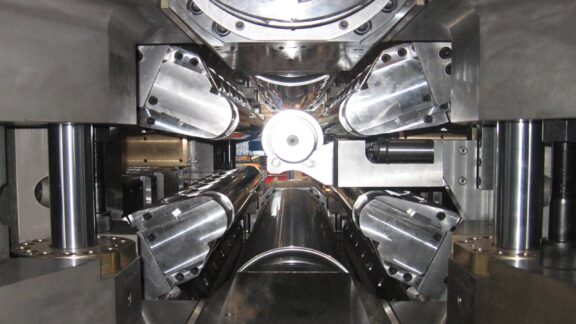

After several successful prototype tests, MQL was installed permanently in the batch tandem cold mill of a major European steel producer. It has been in operation for more than a year, delivering outstanding results.