Mechatronics know-how from Japan, combined with German expertise in Electrics & Automation: the international team of Primetals Technologies has developed an advanced flatness-control system for the production of cold-rolled strip. The system has been designed to complement the 6-high Universal Crown Control Mill (UCM) technology and enables earlier prevention of nonconformities at optimal actuator use. It is based on commonly used flatness-control approaches but adds significant improvements:

- Model-based actuator-efficiency calculation

- Model-based flatness-error optimizer

- Model-based control principle

The UCM Flat encompasses a newly structured control software that makes operation extremely straightforward. The UCM Flat software’s general advantage is its high degree of reliability stemming from the decades-long experience of Primetals Technologies in strip-flatness control. Primetals Technologies has developed an application called “ChartConverter,” which automatically transfers the UCM Flat software to different types of automation platforms and will ensure optimal implementation of UCM Flat far beyond its current reach.

- Higher strip-flatness quality

- Shorter start-up time with mill revamps

- Reliable production planning

- Lower risk for producers’ customers

When used stand-alone in conjunction with a measurement system, the flatness control is an ideal upgrade for existing automation systems. Alternatively, it can be integrated into the larger automation system of Primetals Technologies.

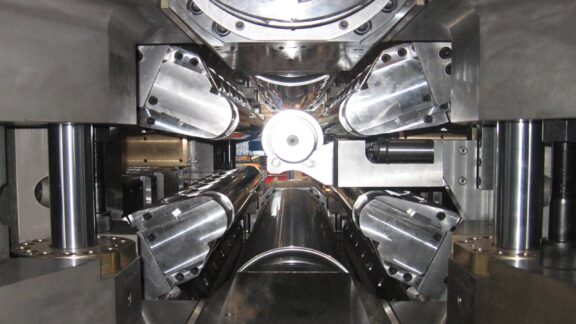

The new control system was successfully tested on a 6-high UCM in the Hiroshima testing facilities of Primetals Technologies. During the pilot phase, the control system and the mechatronics were optimized and further aligned. Early rolling tests showed significant improvements with fewer nonconformities and a reduction of off-gauge material at the head and the tail of the strip.