Digitalization and improvements in knowledge management have been impacting almost all areas of steel production, and maintenance is no exception. Every day, plant and maintenance managers need to find the right balance between optimal reliability and cost. Engineers and operators require precise information on what tasks they are expected to complete by what deadline. Primetals Technologies has developed Maintenance and Asset Technology (MAT) to address all these issues—and to make the lives of maintenance workers much easier.

In order to increase efficiency in maintenance, MAT provides everyone who works with the system with actionable information. This means that each user is supported in their specific role. In addition, MAT can be implemented in a pre-configured state, giving maintenance staff a head start in terms of streamlining their maintenance processes. The goal of MAT is to maximize the return-on-investment of all production-relevant assets (i.e. a plant’s equipment) whilst minimizing the costs associated with production, labor, and raw materials. With MAT, a plant’s performance becomes far more predictable, thereby enabling reliable and effective enterprise resource planning and order scheduling.

MAT: Software-as-a-service

MAT can be obtained as a software-as-a-service solution, which means that maintenance and plant managers don’t have to concern themselves with complex software installations, update procedures, or connectivity issues, because the MAT specialists take care of everything. Primetals Technologies is also responsible for hosting and administrating the system, regular updates, security, and archival tasks, which positively impacts costs and increases convenience. On-premise installations of MAT are also available, if desired. And for those who need it, there is a mobile version of MAT that can be used on tablet computers.

What is actionable information?

One of MAT’s key benefits is that it provides all maintenance staff with information tailored to the position of the respective employee. While other systems are only capable of generating abstract information about issues that need to be resolved or tasks that should be executed, MAT supports workers with actual guidance as to where a problem is located and what needs to be done to resolve it. MAT comes pre-configured for all portfolio elements of Primetals Technologies and includes:

- Templates for the creation of asset-specific maintenance strategies

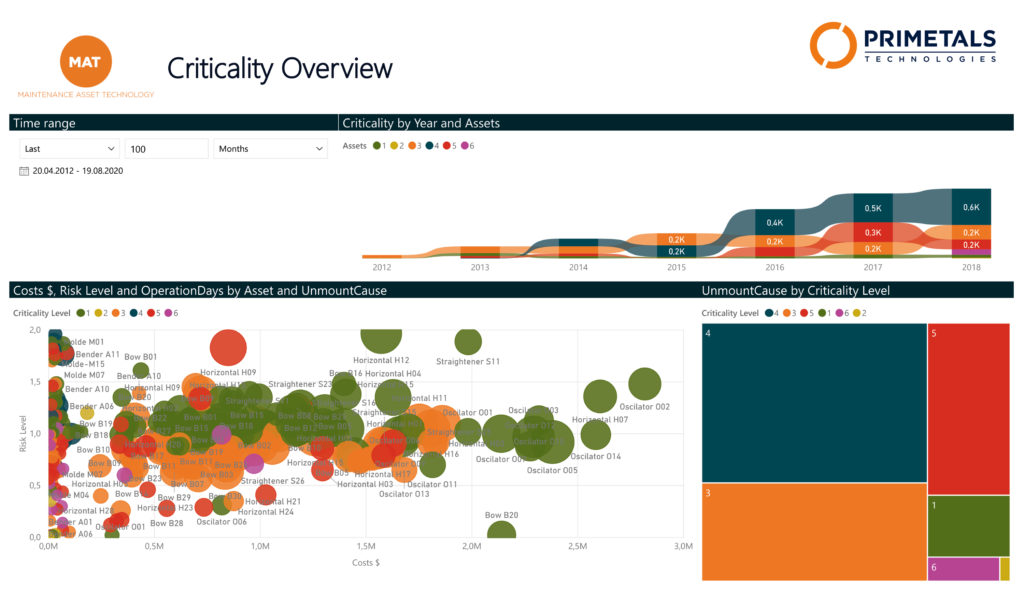

- Analysis of risks, such as equipment failure or potential downtime

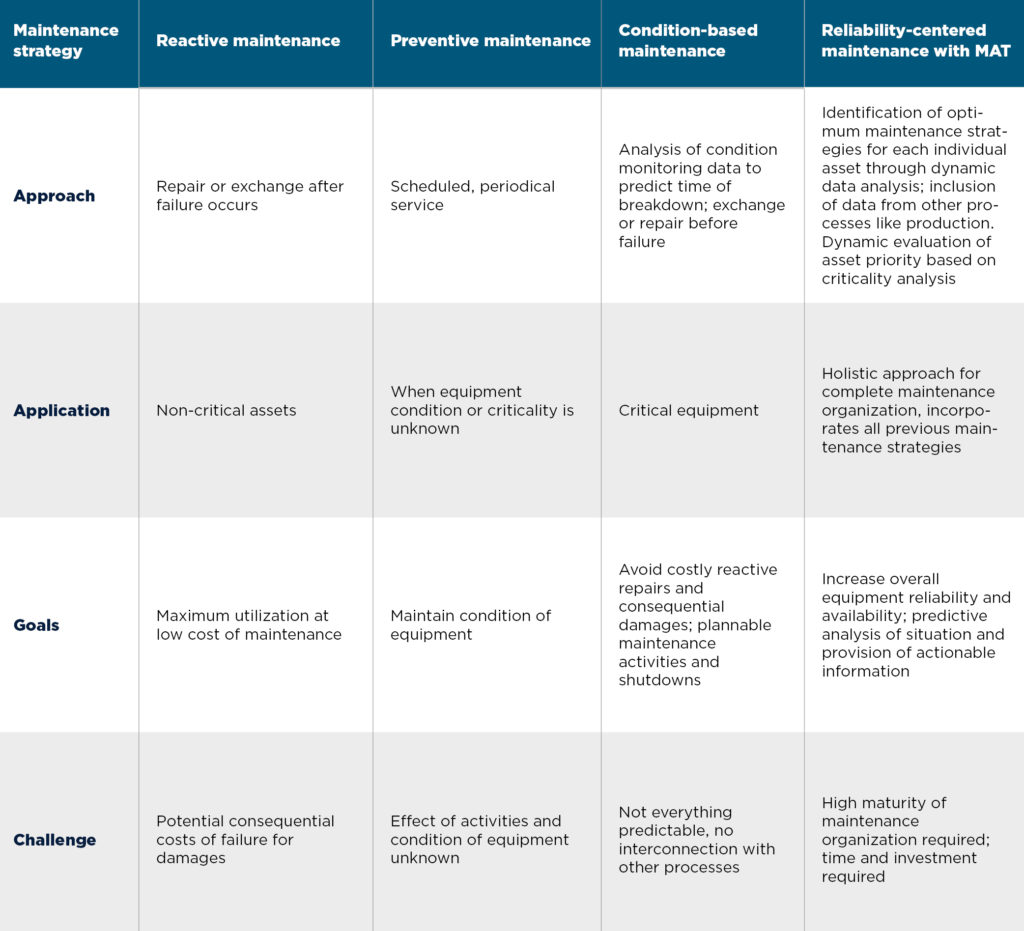

- Guidance toward preventive, condition-based, or reliability-centered maintenance processes

- Provision of best-practice recommendations

- Analytic and predictive features that use

statistical modeling, neural networks, artificial intelligence, and machine learning - Efficient spare-parts management

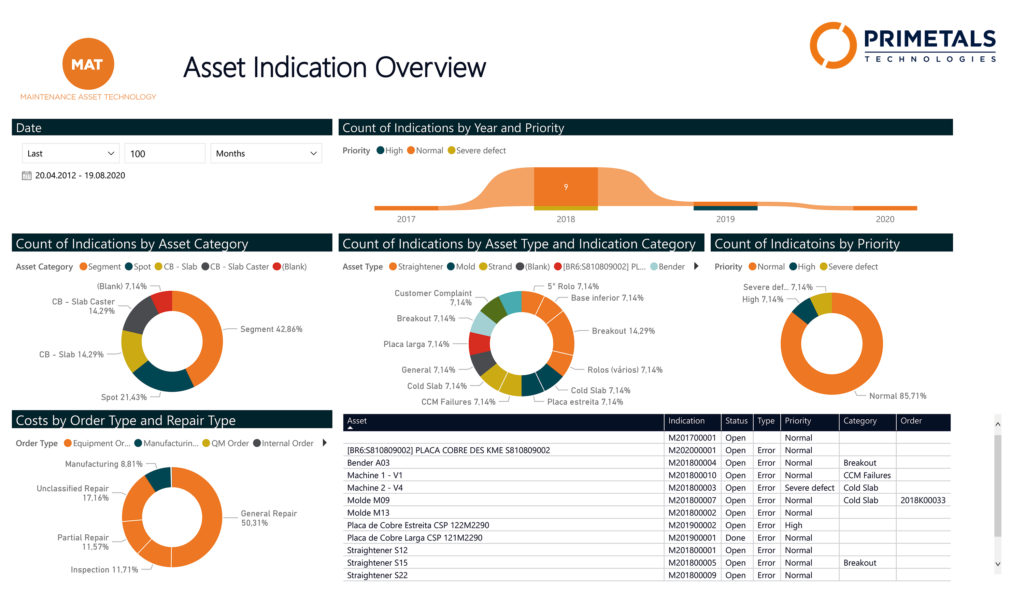

- Up-to-date information of asset health across the complete production chain

- Integration into the e-services from Primetals Technologies—such as the digital spare-parts e-shop

m.buy, the plant-documentation platform m.doc, and the augmented reality services bundle m.ario

A MAT modular system

MAT comprises four smart modular packages: Predictive Maintenance, Planning & Shutdown Optimizer, Reporting & Business Intelligence, and Strategic Asset Management. While highly customizable, MAT comes pre-configured and packed with all the essential features, from criticality assessments and maintenance strategies for specific equipment, to procedures, documentation, and checklists for responding to specific alarms.

Primetals Technologies accompanies steel producers throughout the entire implementation process of MAT and beyond. The experts behind MAT provide support and guidance from the earliest stages of a MAT project, from initial consulting, all the way through to integration, configuration, and training.

A wide range of powerful features

ASSET TRACKING

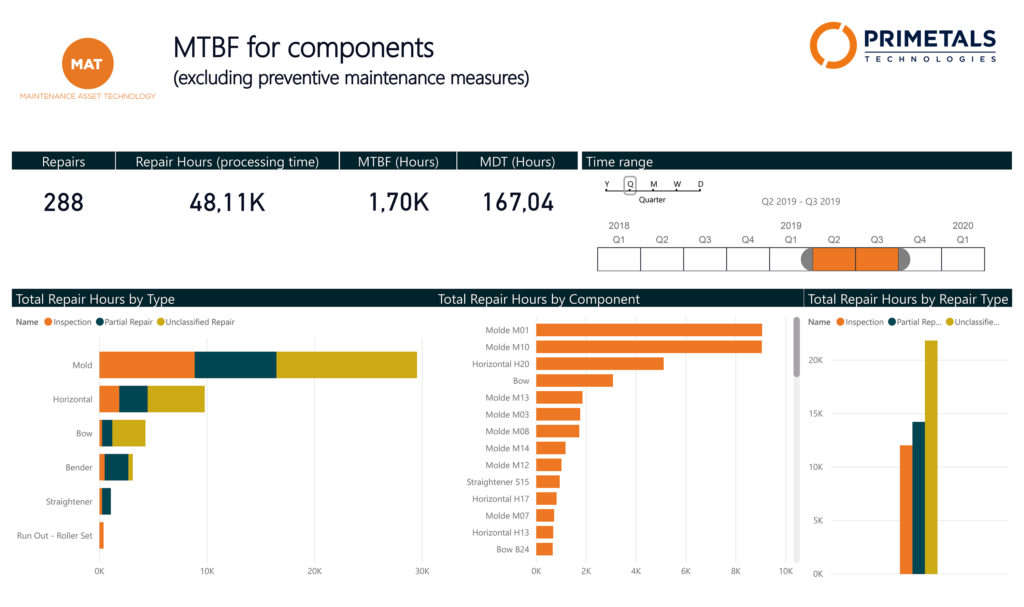

MAT provides instant access to component-part maintenance history, allowing staff to ascertain how often a particular part has been repaired or replaced. Data analytics help to make maintenance more predictable and planning more efficient, thereby reducing ownership costs and boosting productivity.

ADVANCED SCHEDULING

MAT’s work-order-scheduling module allows work orders to be assigned to on-site and field technicians. Advanced visual scheduling makes use of visual tools for managing human resources and equipment, thereby increasing efficiency and minimizing downtime.

RULES EDITOR

The rules editor is a maintenance-assistance tool that offers rule-based suggestions for recurring scenarios. Users can define the

suggestions that should be given in any particular situation, which helps to standardize and therefore streamline processes.

ASSET TRACKING

MAT provides instant access to component-part maintenance history, allowing staff to ascertain how often a particular part has been repaired or replaced. Data analytics help to make maintenance more predictable and planning more efficient, thereby reducing ownership costs and boosting productivity.

WORK-ORDER TRACKING

This graphical support tool is designed to track work orders as well as progress toward completion based on user-defined criteria. Work orders can be created at the click of a button and assigned to on-site or field technicians.

PORTABILITY

MAT runs on tablet computers for on-site and offline use. The mobile app allows service engineers to access work orders, log hours, and add notes offline and synchronize the data later when online. MAT is designed to provide instant access to all knowledge resources and built-in assistance features on the fly, making it a reliable mobile companion.

SEAMLESS INTEGRATION

MAT can interface with various third-party software such as enterprise resource planning (ERP) systems, automation systems, condition monitoring systems, or any other solution with standard application programming interfaces (APIs). Consequently, maintenance-relevant processes are streamlined and redundant tasks are reduced or eliminated entirely.