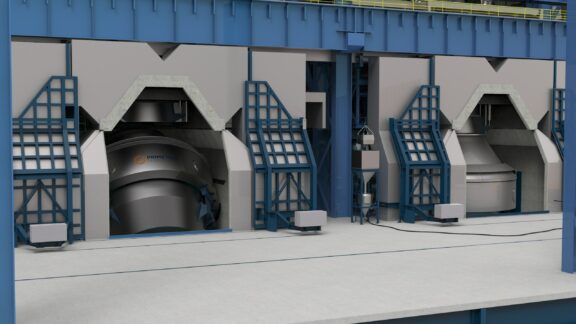

In April, Bosnian steel producer ArcelorMittal Zenica placed an order with Primetals Technologies to replace the vessel of BOF converter #2 and supply associated equipment. An optimized design will increase the vessel volume and make production easier. The well-proven Vaicon Link 2.0 suspension system eliminates maintenance requirements. A new design of the exchangeable bottom ensures reliable sealing and minimizes the risk for leakages. The converter replacement will be executed in an open consortium with the experienced Serbian company GrappS as installation partner. Start-up of the converter is expected by end of 2022.

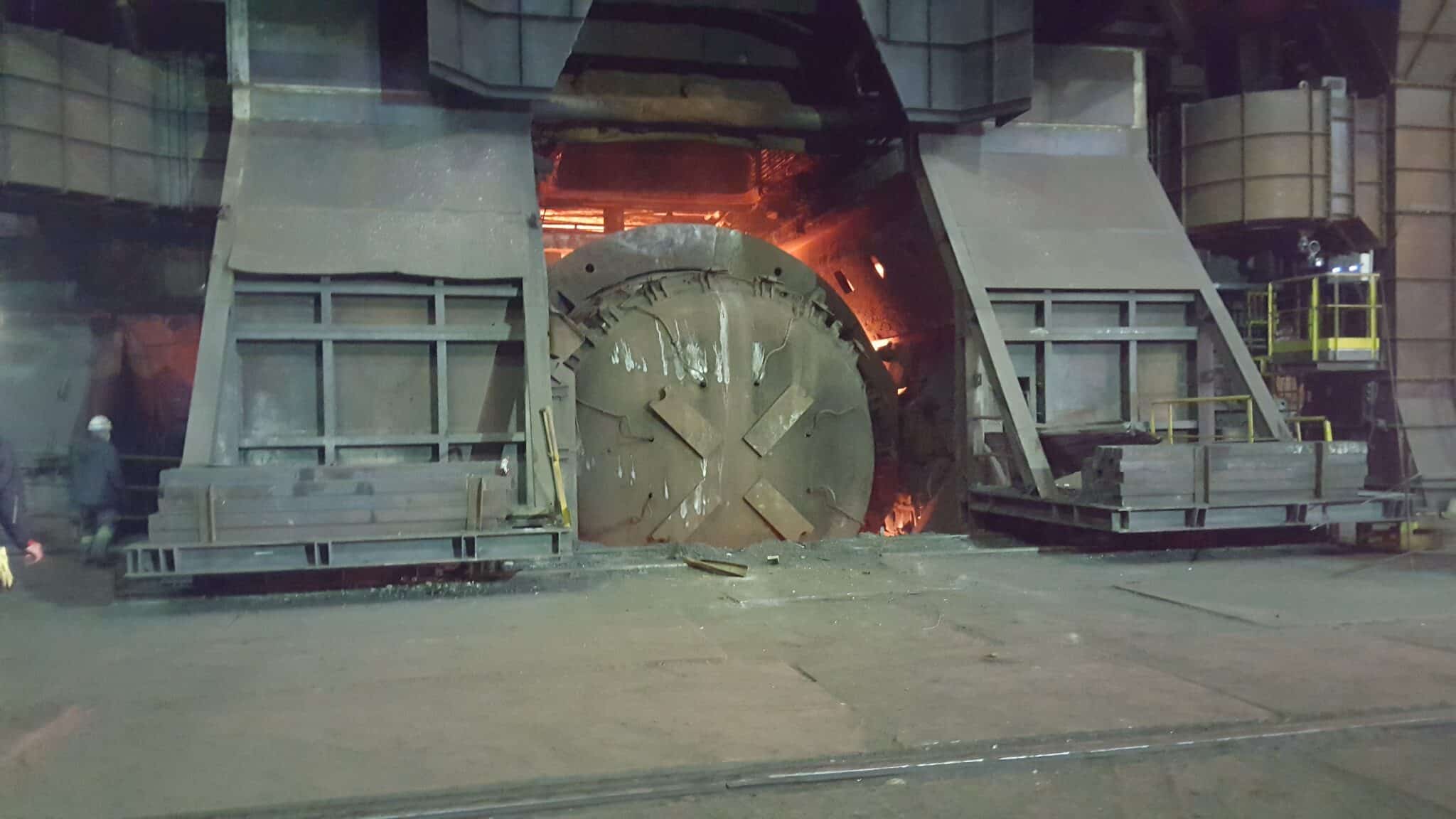

The old BOF converter #2 vessel shell and trunnion ring had reached the end of their lifetimes, with the current bottom design leading to steel leakages in the joint area. For the new 125-ton-BOF converter, Primetals Technologies will be responsible for engineering, manufacturing, project management and quality assurance. The scope of supply includes the BOF vessel, the trunnion ring, the Vaicon Link 2.0 suspension system, bearings and housings and the tilting drive coupling. The lining machine and the detachable bottom exchange device will be modified. In addition, Primetals Technologies will provide the transport to site (Delivery-at-Place) DAP, training on site, and advisory services for erection and commissioning as well as for cold and hot commissioning

The Serbian partner company GrappS will be responsible for dismantling the current converter, preassembly of the new equipment and mechanical erection execution.

ArcelorMittal Zenica is the largest producer of long steel products in the Balkans with a production capacity of almost one million tons per year. The company has integrated route of production. The basic product range includes rebar (in bars and coils), wire rod, mesh and lattice girders. ArcelorMittal Zenica is part of the ArcelorMittal Group, one of the world’s leading steel and mining companies.

MORE INFORMATION

Read the full press release and access contact details and other press resources using the following link: www.primetals.com/press-media/news