Primetals Technologies has received an order from Indian steelmaker Jindal Stainless Ltd. (JSL) to extend the company’s meltshop in Jajpur, Odisha with a new production line. This will more than double JSL’s production capacity at the Jaipur production site to approximately 2.2 million metric tons per year. The order comprises a new AOD converter, a new ladle furnace, a new continuous casting machine, and related dedusting facilities. The AOD production automation system delivers constant fast and low-cost production. Start-up is expected by the end of 2022.

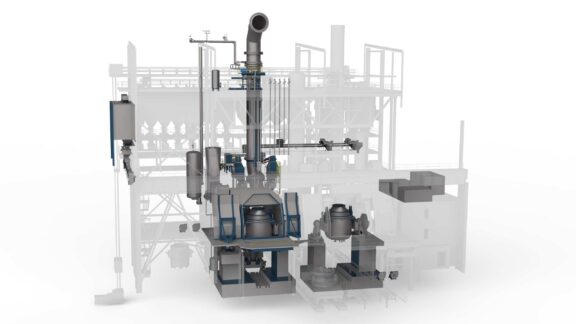

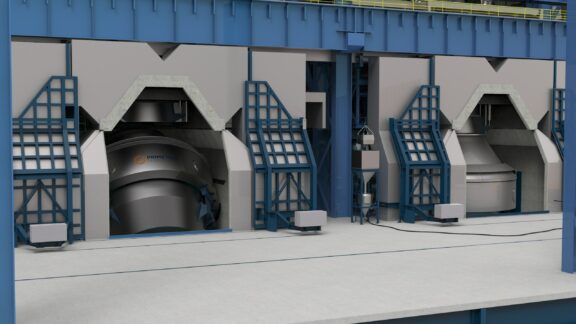

Jindal Stainless Ltd. was founded in 1970 by Shri O.P. Jindal and is the largest stainless-steel producers in India. The company is one of the world’s top ten stainless steel conglomerates. The Jindal Stainless Group has an actual annual crude steel capacity of 1.9 million metric tons. Primetals Technologies will supply the 150-ton AOD plant with top blowing lance, an exchangeable converter with Vaicon Quick suspension, a tilting drive with damper system and a gas mixing station.

Primetals Technologies Vaicon Damper leads to a more stable AOD production with reduced vibrations and extended tilting drive service life. The material handling system will be adapted. The basic automation system as well as the level 2 process optimization are also included. In 2019, Primetals Technologies already had installed successfully level 2 automation system for the existing AOD #1.

The 150-ton ladle furnace to be supplied by Primetals Technologies features a water-cooled roof and the well proven Melt Expert electrode control system. The scope of supply also includes the high-current system and the current conducting arms. The single-strand continuous slab caster is designed to produce slabs in a width range of 850 to 1,680 millimeters at thicknesses of 160 to 220 millimeters. The metallurgical length amounts to 25.65 meters. It will process ferritic and austenitic stainless 300 and stainless 400 series steels as well as Duplex stainless grades

The caster is equipped with latest state of the art technology, including LevCon mold level control, DynaFlex mold oscillation, Mold Expert breakout prevention and DynaPhase phase transformation modelling for maximum possible slab quality. Latest design DynaGap Soft Reduction 3D in all segments, Dynacs 3D spray cooling, and Quality Expert for on-line slab quality assessment are also provided.

MORE INFORMATION

Read the full press release and access contact details and other press resources using the following link: www.primetals.com/press-media/news