German steel producer Hüttenwerke Krupp Mannesmann (HKM) operates an integrated steel plant in Duisburg-Huckingen, now featuring two new ladle-treatment stands. Producing over 1,800 different steel grades and a production capacity of 5.6 million tons per year of slabs and round bars, HKM is one of Germany’s largest steel producers. Primetals Technologies has a history at HKM, supplying the BOF trunnion ring for converter No. 2, which began operation in 2016, and modernization of continuous slab caster No. 3 in 2015. Recently, HKM has granted Primetals Technologies the final acceptance certificate for the two 285-ton new ladle-treatment stands ordered in 2018.

Implemented with LiquiRob, a robotic system designed to increase safety and improve sample accuracy, the two stands can handle 5.2 million tons of liquid steel per year. LiquiRob has successfully replaced semi-automatic sampling solutions operated by personnel, and is able to perform tasks from connecting or disconnecting equipment to and from the ladle to measuring temperature and hydrogen content. The application of this fully automated system, alongside the automatically coupling purging gas systems, primes these stands for digitalization in the future.

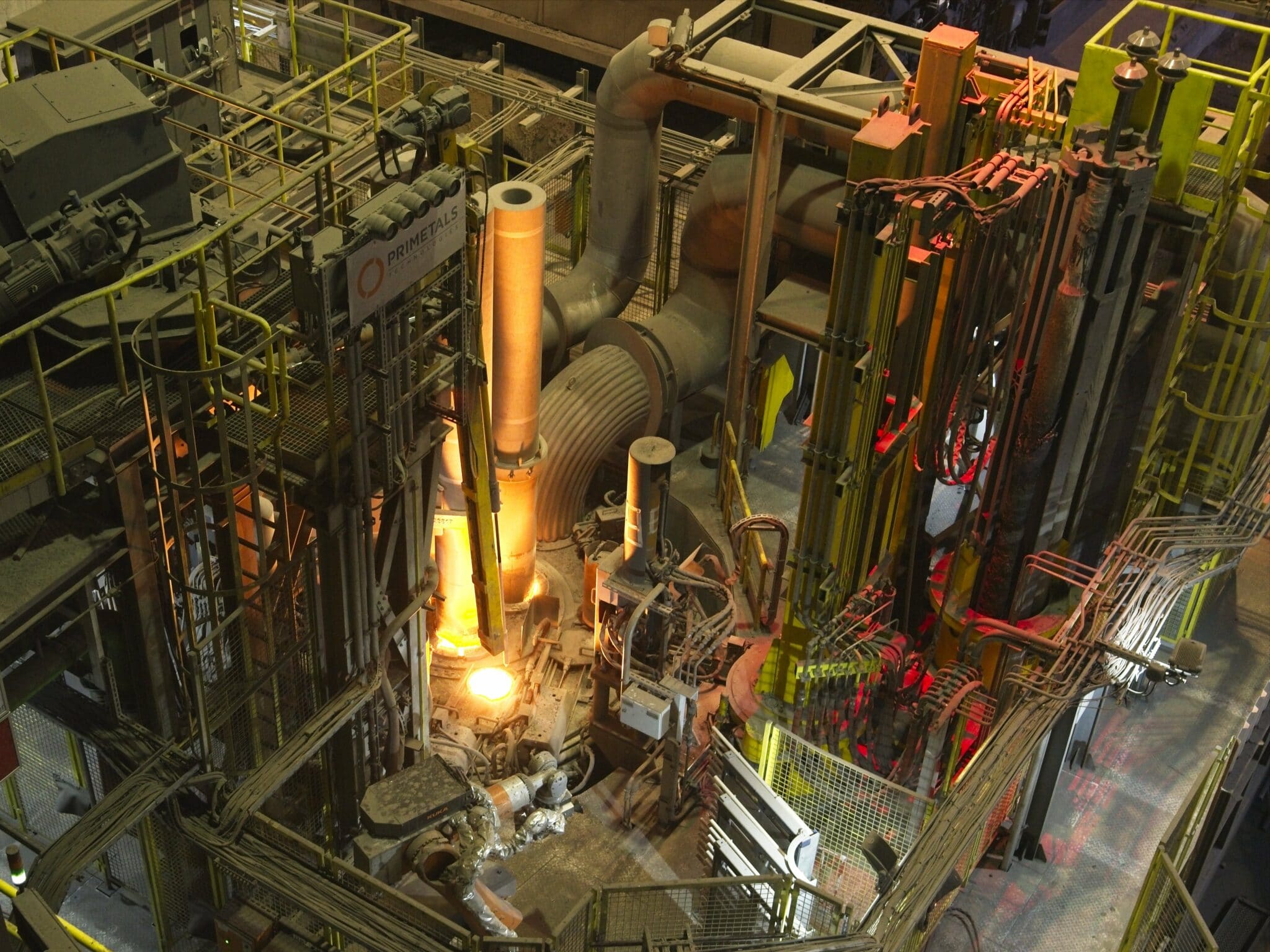

The ladle-treatment stands utilize electric arc technology and are equipped with copper-clad lids that increase the service life of each stand and ensures the production of high-quality steel. The copper-clad lids also ensure that production capacity is reached, by accommodating a high-performance high-current system. The ladle-treatment stands handle all melts produced in the two BOF converters in Duisburg-Huckingen without exception, meaning the design and implementation of the ladle-treatment stands integrates and operates smoothly with a high level of availability to meet the demands of the production line.

The tasks of the ladle-treatment stands are to reduce refractory consumption of the converters by lowering tapping temperature by up to 50°C, reduce phosphorus content in the steel, produce melts that necessitate a higher degree of alloying, increase the optional use of pig iron or scrap in steelmaking, optimize the use of lime, and reduce the amount of slag. By lowering the phosphorous content of the melts, the stands make higher alloying percentages a possibility. Additionally, Primetals Technologies also aided with the installation of the furnace transformers for the electrical supply of the treatment stands, control systems, and the electrics and automation. Adapting the design to the limited space available in the steel plant was key to meeting HKM’s needs. By implementing automated systems, which increase safety and efficiency, the ladle-treatment stands at HKM reduce operational expenditures and ensure high-quality end products.