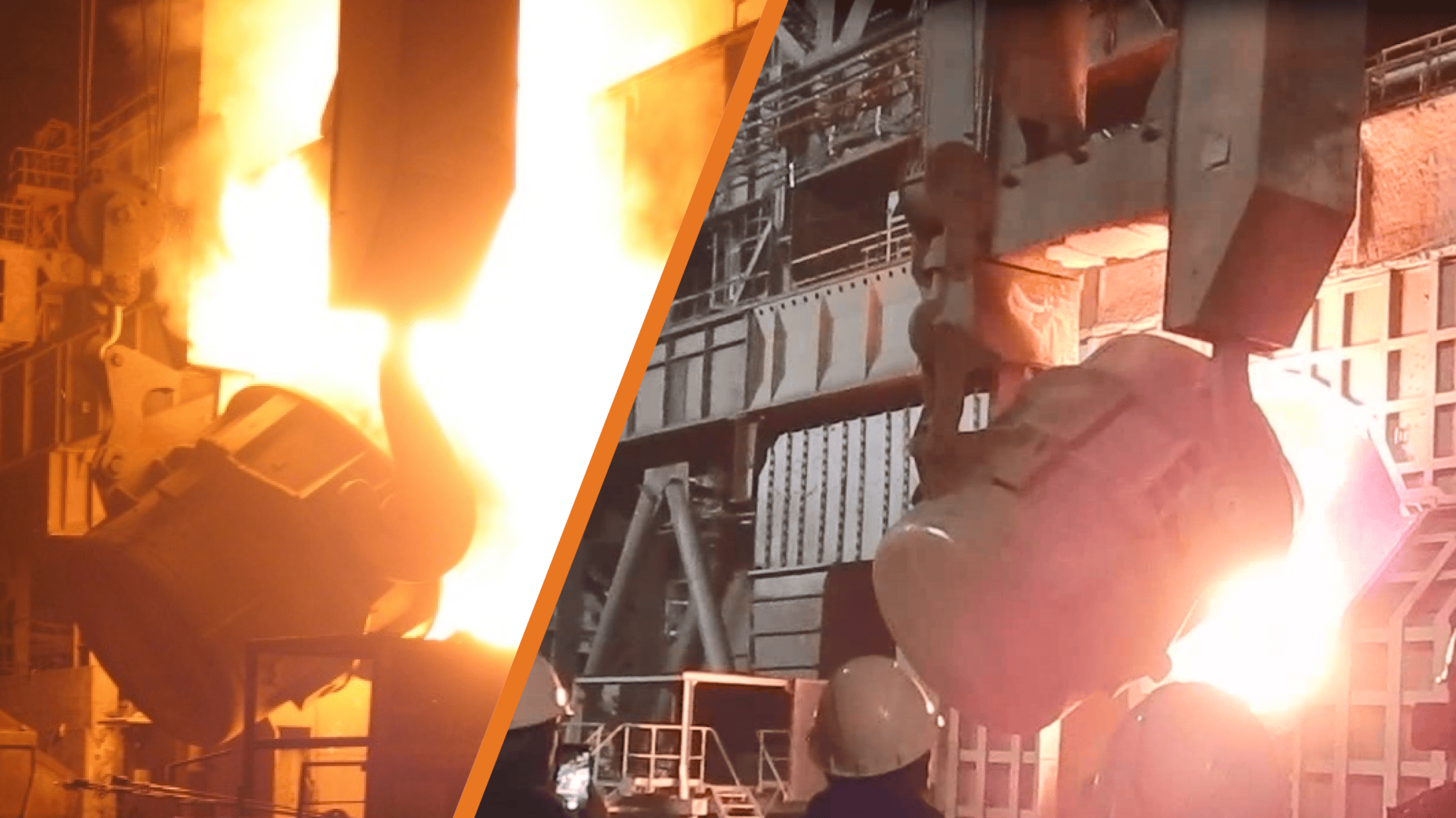

NLMK Group issued the final acceptance certificates for off-gas systems at LD converters (BOFs) No. 2 and 3 at steel plant LD2 in Lipetsk. The project aims to reduce emissions at the steel plant to levels lower than European standards, improve the heat-recovery system to supply steam to the existing network, use the converter’s off-gas for further utilization, and increase productivity. An increase in productivity was possible thanks to optimal synchronization of the metallurgical aspects, the dedusting system, and the automation. Due to the pandemic’s challenges and concerns, Primetals Technologies and NLMK joined forces and developed a unique acceleration program to tackle pandemic-related issues. Thanks to these efforts, the project was completed on schedule.

The primary BOF off-gas system was replaced by a sophisticated wet dedusting system, which achieved dust concentrations below European standards and fulfilled Best Available Technology (BAT) requirements. The new secondary dedusting system was designed to capture any emissions that would have remained inside the plant or were previously escaping through the roof. Additionally, the heat-recovery system was replaced by an advanced cooling-stack system for steam generation.

Entirely new Level 1 and 2 automation systems greatly improved production, including the metallurgical model Dynacon. The modernization process was performed for both BOFs in series. Although the project was affected by challenges around Covid-19, the commissioning and production ramp-up were completed quickly because of coordination efforts from the teams involved.