One common source of yield loss in cold-rolling mills is the strip’s unrolled head and tail ends. As each coil is loaded into the pay-off reel, sent through the rolling stand, and coiled onto the reel, a substantial yield loss between 1.5–3 percent, or more, of overall production occurs.

The process of loading coils and preparing the strip is also labor-intensive. It requires the involvement of skilled operators to send the strip through the mill and lock it into place. The process is commonplace in mill operation: depending on mill type, production capacities, and product mix, it can take place over 6,000 times a year. Reliance on this method creates a bottleneck in production, thus further increasing operational expenditures.

Smarter Threading

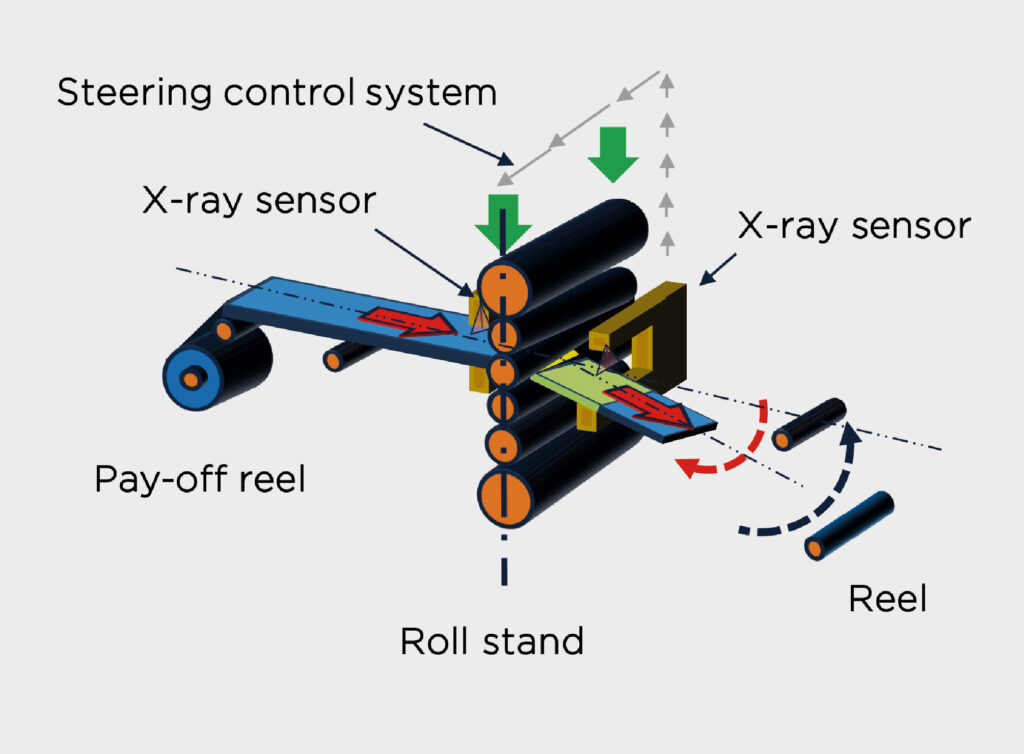

R&D specialists at Primetals Technologies have recently developed an efficient, stable, and consistent method to solve these issues at cold-rolling mills. The solution lowers the amount of scrap (yield loss) generated and makes the reduction process less labor-intensive. This new technology utilizes advanced x-ray sensor technology and a new control system for cold-rolling mills. While cold-rolling mills have relied on x-ray sensors to gauge centerline strip thickness, specialists have developed a new x-ray sensor to also detect any lateral movement of the strip. By measuring the movement of the strip, the sensor helps prevent various kinds of malfunctions even when threading at high speeds. Combined with the mill’s automated control system, the real-time data provided by the sensor accounts for necessary adjustments on either side of the strip. Remarkably, this controlled steering works even at high reduction levels and speeds up to 30 meters per minute.

The solution’s control system facilitates the automatic threading of the strip. After opening the mill stand and sending the strip head end through the roll-gap between the work rolls and centering, the roll-gap is adjusted to the target thickness for the respective pass. The rolling process can start immediately without any applied head tension onto the strip. The automated system means that no human interaction is required, and rolling can begin without stopping the mill. By eliminating the need to manually lock the strip into the reel or establish winding tension, this innovation accelerates production time and keeps operational expenditures low. This automated system ensures that more of the strip can be processed and transformed into a saleable product, meaning less scrap, and this technology can also be applied to the strip tail from the pay-off reel. The R&D team, drawing from Primetals Technologies’ international locations, estimates a 0.6 percent or more increase in product yields, depending on steel grades and product dimensions.

The x-ray sensor and the data it generates are combined with a steering control system to automatically thread and adjust the strip—and to ensure the production of high-quality cold-rolled steel. Smart Strip Threading also greatly improves consistency of production.

Integrated Solutions for Reversing Cold Mills

Dedicated specialists have tested the Smart Strip Threading technology at full-scale test facilities and are in the final stages of development at Primetals Technologies in Hiroshima, Japan. As a supplier of Smart Strip Threading technology and other unique rolling technologies, Primetals Technologies can readily upgrade existing cold-rolling mills and incorporate this technology as a standard feature of cold-rolling mills in the future.

MORE INFORMATION

Click here to read more on cold-rolling mills by Primetals Technologies