A joint venture of Chinese steel producers Taiyuan Iron and Steel Group Co. (TISCO) and Shandong Xinhai Industry have granted the final acceptance certificate (FAC) to Primetals Technologies for an extensive combination of meltshop and casting equipment at a stainless-steel plant in Linyi, Shandong province, China.

TISCO is a holding subsidiary of China Baowu Iron and Steel Group, founded in 1934. TISCO focuses on developing special steels—e.g., ultra-wide, ultra-thick, ultra-thin strip tubes and high-quality silicon steel for electric vehicles. Based in Linyi, China, Shandong Xinhai Industry processes, manufactures, and distributes metal products. The company produces plating alloys, high nickel alloys, manganese alloys, and other products.

Optimized Results

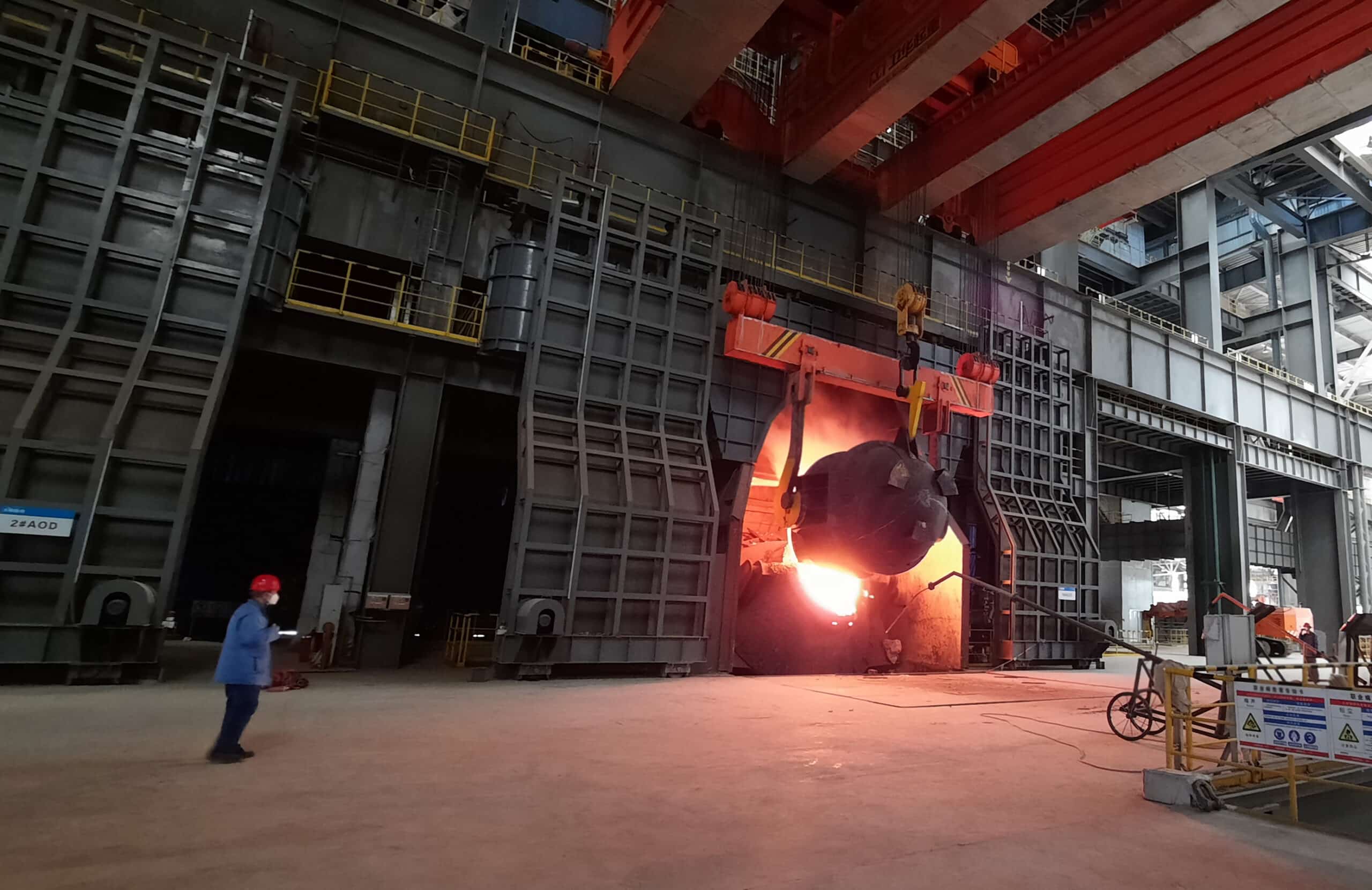

All equipment has been implemented successfully, with performance figures exceeding expectations. Charge-to-tap times of less than 89 minutes, including the intermediate deslagging process, are a regular occurrence, which is particularly remarkable as the mass build-up of materials in the AOD converter is high.

The process optimization systems are also demonstrating excellent results. The contractual performance value for the hitting rate, i.e., 85 percent for a temperature range from -10 to +15 degrees Celsius, was already reached during startup. These systems are now exhibiting hitting rates of almost 100 percent for the given temperature and carbon windows. In addition, plant availability was above 99 percent during the performance test phase.

AOD Supplier

Primetals Technologies is a leading provider of AOD equipment, which was one of the main factors contributing to the customer’s choice of supplier. The portfolio also includes special processes, like intermediate deslagging, and process optimization systems tailored to the AOD process. An additional important factor for the customer was Primetals Technologies’ extensive reference base, which includes several major stainless steelmaking projects in China.

Since 1988, Primetals Technologies has supplied eight new slab casters to TISCO, and the Chinese steel producer has tasked Primetals Technologies with 24 casting projects to date. The two stainless slab casters at the site in Linyi have an annual capacity of 0.9 and 1.2 million tons and a maximum width of 1,600 and 2,100, respectively. The bow radius is 9 meters.

- Two AOD converters and two AOD/DeSi converters

- Converter suspensions

- Trunnion rings

- Pedestals and main bearings

- Tilting drives

- Top lance equipment and process valve stations

- Converter exchange car

- Process control system “AOD Controller”

- Process optimization system “AOD Optimizer”

- Two continuous slab casters

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.