The steel plant in Gent is part of ArcelorMittal Europe’s Flat Products division. The plant produces high-quality flat products for various markets, including the automotive, household electrical appliances, and construction industries. In Bremen, ArcelorMittal produces more than 3.6 million tons of steel annually for several markets, including the automotive industry.

Recently, ArcelorMittal ordered new copper staves for both steel plants. Dealing with the wear and bending of current copper staves, the steelworks in Gent and ArcelorMittal sought an ideal substitute technology.

Bend Prevention and Reduced Wear

ArcelorMittal has ordered multiple rows of copper staves for the blast furnace in Gent, Belgium. Using a well-proven anti-bending solution, the copper stave technology prevents stave corner bending caused by thermal effects and stave bending around pipe connections. In turn, it helps avoid cracking in critical weldments and an unnecessary loss of cooling water.

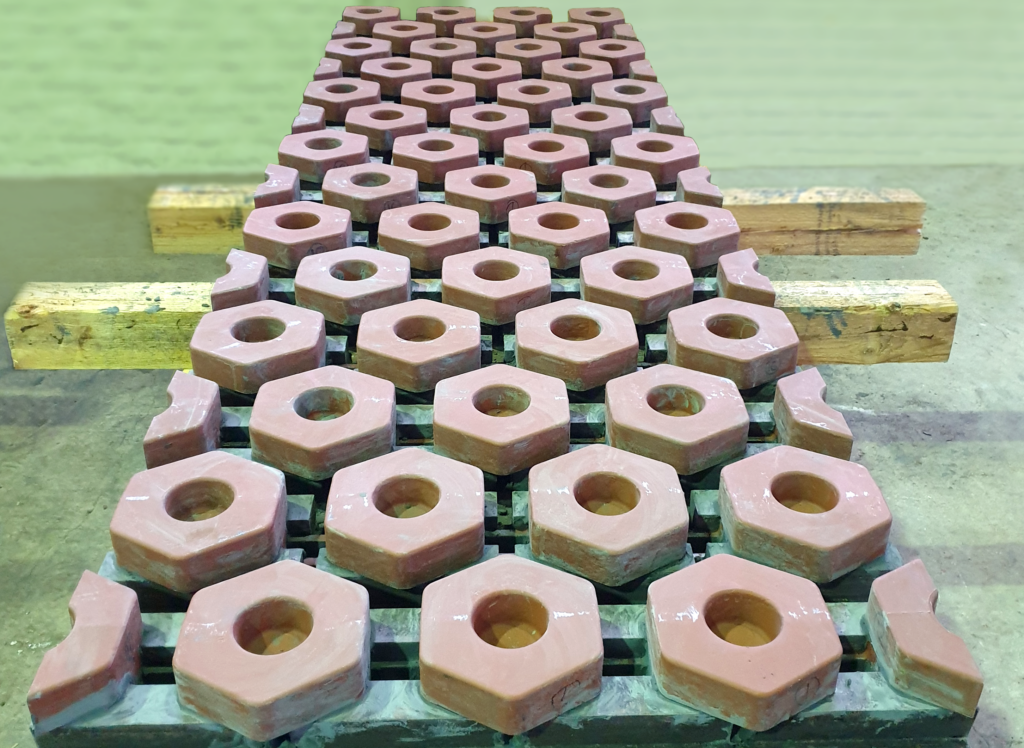

The rows of staves in the stack also feature slide-in hexagonal inserts. These inserts capture and retain unreduced materials on the staves’ hot face, leading to significantly less wear and lower maintenance-related expenditures.

Primetals Technologies will also supply ArcelorMittal with multiple rows of copper staves for the steel plant in Bremen, Germany. The current staves are at the end of their lifetime, and ArcelorMittal has asked for replacement staves.

Recent Orders from Primetals Technologies

Over the last few years, ArcelorMittal has placed several stave orders with Primetals Technologies. In July 2022, new cast-iron staves were installed in the blast furnace at the steel producer’s plant in Newcastle, South Africa.

These staves feature a tailormade anti-bending solution and a fixing system that eliminates the risk of bolts being pulled out—a common cause of cooling pipe failures resulting in cooling water leakage into the furnace. In addition, Primetals Technologies will be supplying copper and cast-iron staves to ArcelorMittal Poland for the relining of a blast furnace.

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.