This post is also available in: 简体中文 (Chinese (Simplified))

Mechatronics papers will be presented by Primetals Technologies specialists at the ESTAD Congress covering the topics of improved strip-steering control using an optical measurement device, inline determination of the mechanical properties of steel strip on the basis of electromagnetic parameters, and improved strip side trimming applying optical inspection devices.

Next-Generation Strip-Steering Controller Based on Optical Measurements of Strip Alignment and Curvature for Hot-Finishing Mills

Principal author: Andreas Lorenz

Paper number: 225

A stable and straight strip run without cobbles is crucial for system stability and safety of the rolling process in a finishing mill. This is a precondition to attain high shape quality and the required mill output. A new integrated robust control structure is presented that stabilizes strip run. Using asymmetric roll- stand models, including a roll-gap model and a finite element (FE)-strip model, a holistic simulation of the strip run in a finishing mill is achieved. This includes the simulation of lateral displacements and the resulting tension distribution of the whole strip. The control structure consists of a combination of strip position and differential tension controllers. Operators may choose between different modes. The measurement of the strip position between the mills was solved by the installation of an optical measurement device based on area-scan cameras positioned between each mill stand. New image processing algorithms were developed in order to obtain reliable results, even under the extremely harsh conditions prevailing between the mill stands. The equipment transmits strip alignment data as well as curvature data of the strip at each mill stand to the position controllers. Differential force and sum force are delivered by encoders mounted at the drive and operator sides of the looper and serve as input for the differential tension controller. Simulation results demonstrate the achievable improvements.

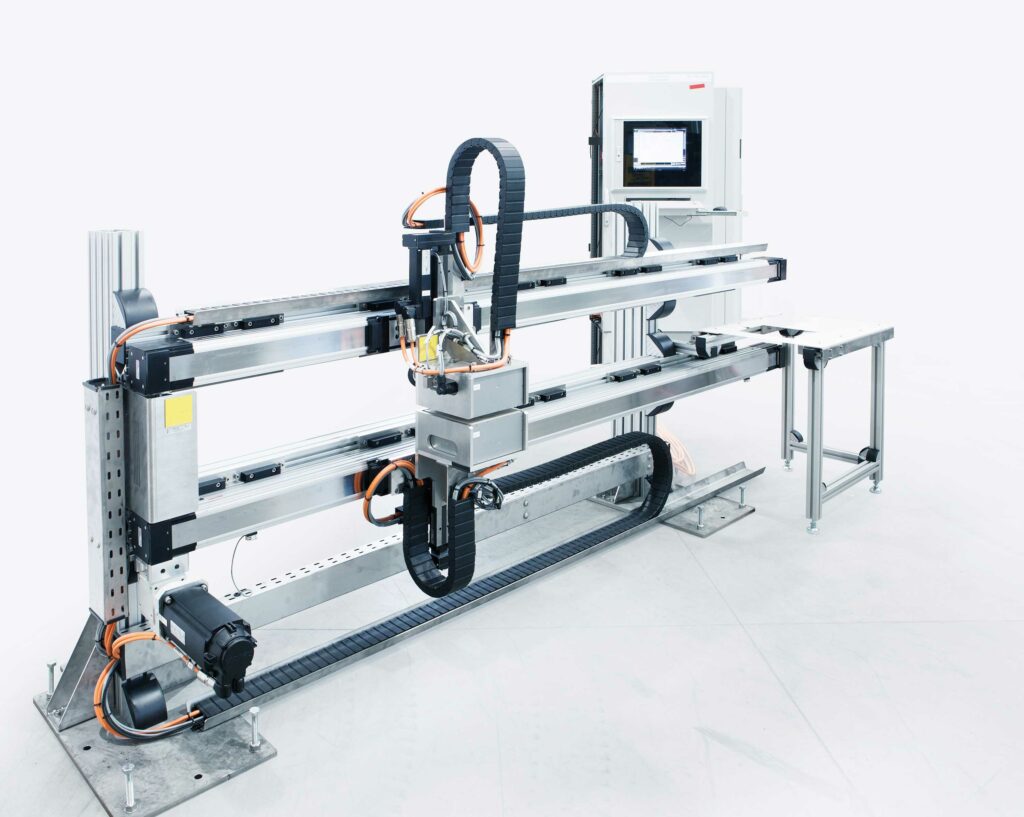

Inline Measurement of Electromagnetic Parameters and Their Application for Characterizing the Mechanical Properties of Steel Strip with a Focus on Hardness

Principal author: Dr. Alois Koppler

Paper number: 219

Inline measurement of the mechanical properties of steel strip with contact-free and non-destructive techniques offers considerable potential for further technological optimization and new applications. Up until now, it has not been possible to perform direct inline strip measurements. The PropertyMon system from Primetals Technologies employs state-of-the-art methods that allow indirect measurements to be carried out using electromagnetic signals. By measuring the magnetization of steel strip, the mechanical and magnetic properties can be calculated. This is done by applying regression calculations where the coefficients are derived from laboratory sample testing. This leads to reliable results for tensile strength and yield strength, etc. – as demonstrated by system installations.

PropertyMon exhibits some unique features such as the combined measurement of strength and electromagnetic properties or directional measurements, i.e., longitudinal and transversal to the rolling direction. For the first time, test trials to determine strip hardness were carried out in a heat-treatment line of a German steel producer. The initial results are presented and show that the measurement system can provide continuous hardness calculations with a high degree of accuracy for online process monitoring and quality control. This approach complements and supports standardized, destructive testing procedures in the laboratory.

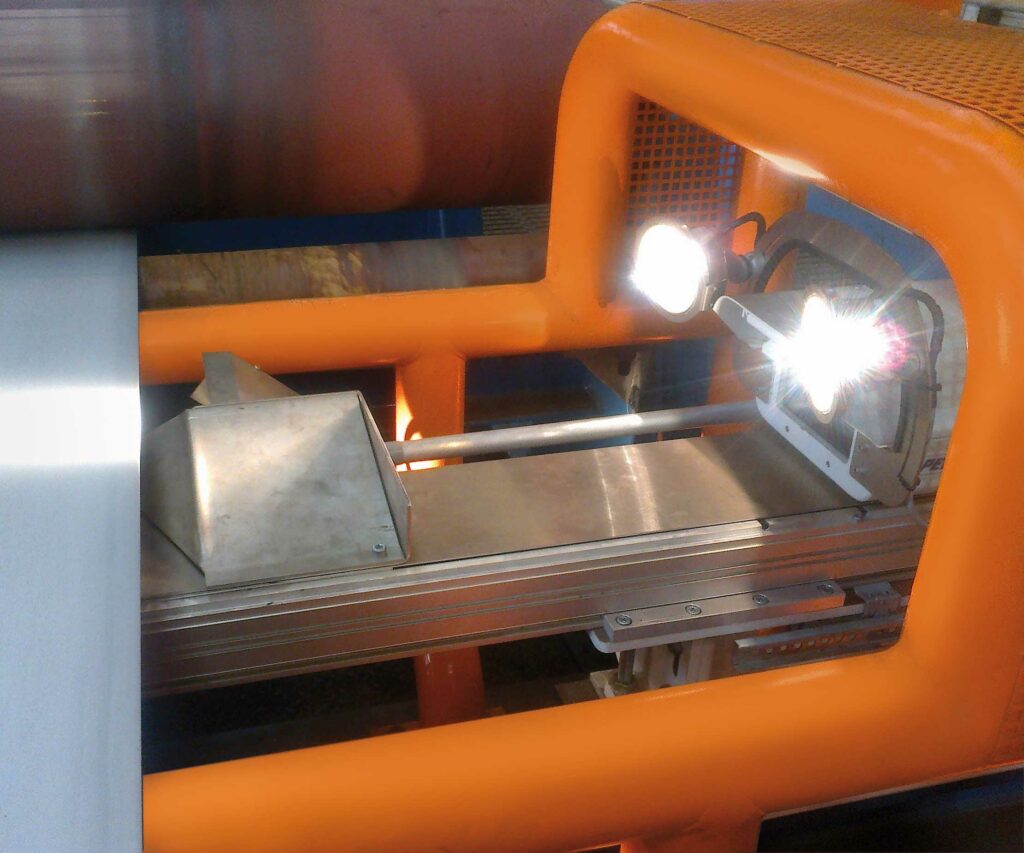

Improvement of Side-Trimming Quality Based on the Use of Optical Inspection Devices

Principal author: Helmut Hlobil

Paper number: 218

Problems arising during the side-trimming process in pickling lines may lead to strip-edge defects. This, in turn, can cause lower yield performance, loss in product quality, unnecessary maintenance efforts as well as higher tool costs. The paper describes project results that show the improvements that were achieved in the side-trimming process. This was done in two steps: The first step was the identification of the quality defects and the impact to the subsequent processes and on maintenance. The second step was the implementation and evaluation of specific improvement measures that were carried out at the plant. The installed optical inspection device known as EdgeMon served as the basis for strip-edge examinations and the subsequent improvements in side-trimming quality. Its functionality and its positive impact on the project results are described in this paper.