This post is also available in: 简体中文 (Chinese (Simplified))

The quote “Nothing great is easy” has been used for many decades, and the ability to produce high-quality rolled products consistently and rapidly is no exception. Primetals Technologies offers a whole range of solutions to meet the challenges facing aluminum rolling and steel plate mills.

In striving to produce world-class material, Primetals Technologies has worked all over the world with steel and aluminum producers to create new products at higher and higher quality levels without reducing mill throughput or reliability. A number of process optimization examples for aluminum rolling mills and steel plate mills are described in the following:

Significant improvements with small changes

Primetals Technologies was recently contracted to visit an existing aluminum foil mill in order to improve hydraulic automation gauge control (HAGC) and roll profile systems that have been operating for several years, but not at their highest potential. The changes included not only tuning the system parameters such as system gains, but also rethinking various control logic settings. One outcome of this review led to moving the software filter from measurement feedback to the controller output. This relatively innocuous change created significantly faster response times and improved flatness.

Optimized schedule increases quantity and quality

Improvements in quantity as well as quality were made by one European aluminum producer through the optimization of a specific low-load rolling schedule. Engineers at Primetals Technologies studied the aluminum rolling mill design and carried out a series of calculations using in-house models to ascertain what would be possible. The conclusion of the calculations was that a downward revision of the low load limit was technically feasible.

The desired change to the minimum load limit was successfully made and the control loops retuned. At very low speeds, the heat generated by deforming the material is small, and it is difficult to get the ideal temperature difference between work rolls and the coolant to ensure high-quality flatness performance. The increased rolling speeds resulted in greater heat generation rates in the mill bite. This, in turn, led to more stable flatness performance. Results from the initial trials for aluminum rolling speeds are impressive, with a near doubling of rolling speed to 700 meters per minute (mpm).

Comprehensive process know-how for optimized throughput and lower costs

In cooperation with a major European steel producer, Primetals Technologies established a reliable route for the production of normalized steel plates. The benefits included reduced processing costs for these particular plates, and consequently a lower load on the existing heat-treatment line that allowed throughput to be optimized in this area.

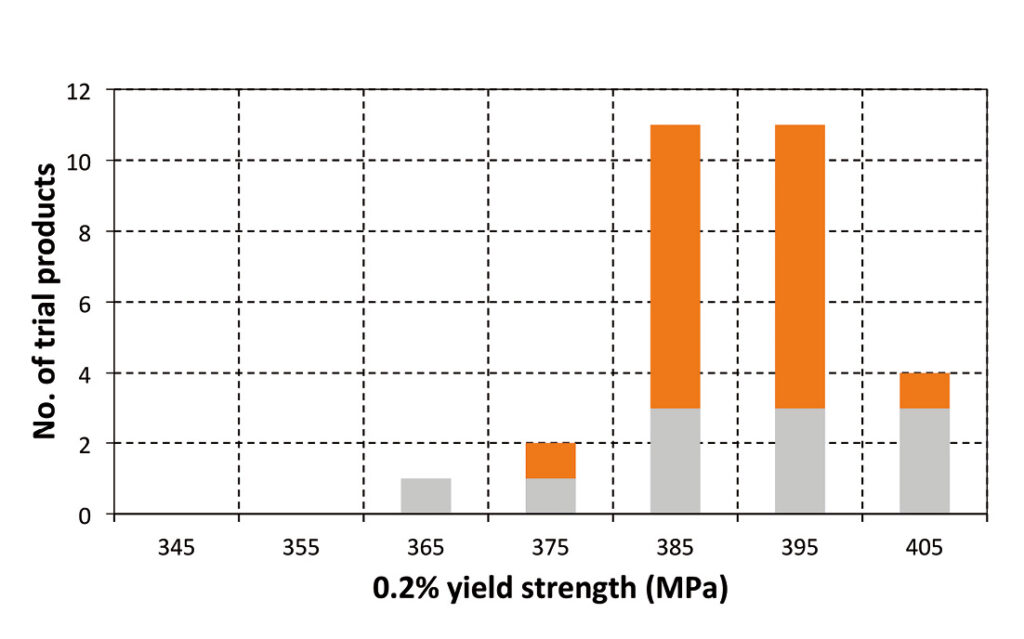

The aim of the work was to develop and expand the normalized rolling production range for structural steel grade S355J2+N. Primetals Technologies provided process know-how for the whole process and production route in the areas of material chemistry, reheating furnace practice, rolling schedules, cooling bed and hot stacking. Results for samples taken from both the end and body sections of a selection of the trial products manufactured with two slab compositions were compared to EN Standard 10025-2. The requirements for this thickness are 0.2% offset yield strength of 345 MPa, and an impact toughness of 27 J at -20°C for the normalized rolled delivery condition.

All products passed the EN Standard 10025-2 requirements for yield strength and exhibited only a small spread in the data set (Figure 1). As a result of these trials, up to 72% of the customer’s product mix for normalized plates could be produced by normalized rolling, thus dramatically increasing the capacity for normalized products. In addition, the costs of the offline heat treatment could be saved; the environmental impact of the process was lower because fuel did not have to be burned for the heat-treatment process; and alloying costs were reduced through the use of specific material chemistries prescribed by Primetals Technologies.

Excellent cooperation, excellent results

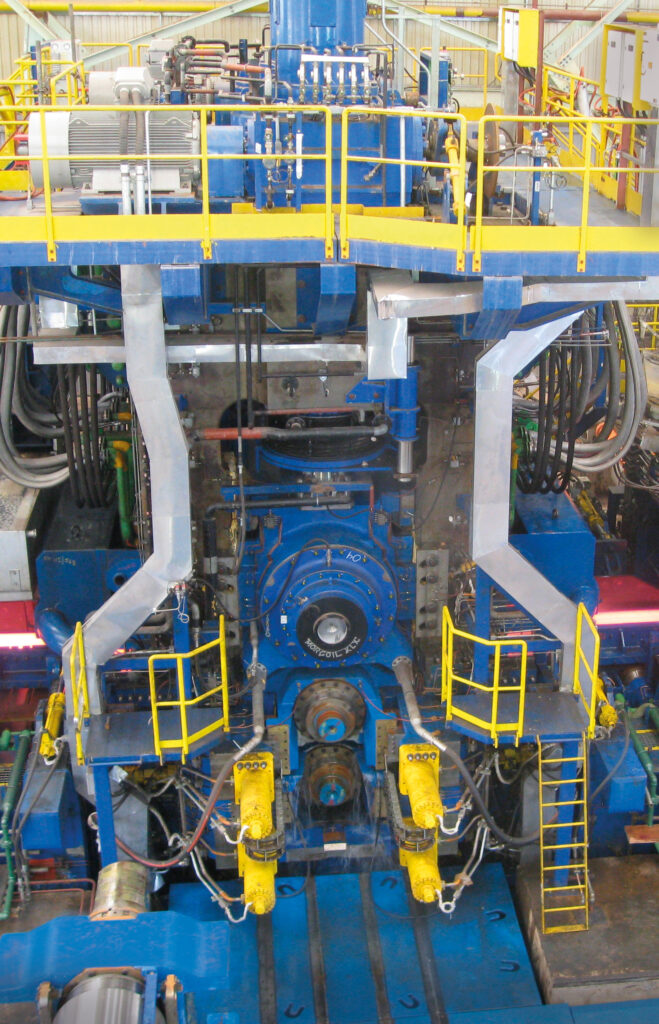

Primetals Technologies was asked to work with a well-established plate manufacturer to help produce very wide (>4 m) plates at 6 mm and 7 mm thicknesses with low levels of cold leveling. The customer was very familiar with the plate rolling process and had been rolling many difficult grades for the international market with success, but at higher thicknesses and lower aspect ratios. Site visits along with preliminary trials identified what could be achieved, which practices were used as standard and what, if any, mechanical changes would be required. A full mill survey was then conducted by Primetals Technologies using the latest laser survey equipment, and the necessary changes were implemented by the customer.

To achieve consistency, the rolling schedules for all grades and sizes were studied in depth, which resulted in the model controlling the mill being tuned to ensure that the predicted load and torque accuracy was within +/-10% of the actual values. As a result of the excellent cooperation between the plate producer and Primetals Technologies, the final trial resulted in direct shipping values of 90% compared to the original value of less than 30%. The main photo for this article shows the high degree of final product flatness on the cooling bed.

Interview with

Hermenio Pinto Gonçalves

Industrial, Engineering and EHS* Corporate Director, Gerdau, Porto Alegre, Brazil

What are the main challenges that your company is currently facing?

Hermenio Pinto Gonҫalves: Our markets are in the United States, Brazil and the rest of South America. Each of these regions has a different situation. In the United States steel demand is currently growing and prices are improving. In Brazil there are problems related to the economy. Maybe in two years or so we will see some improvements here. South America is generally open for imports because most of the countries don’t have a large local steel industry, so we have to compete here with other steel suppliers.

How do you see the future of the steel industry in your market area, and what factors need to be taken into consideration?

Gonҫalves: Our markets are in the United States, Brazil and the rest of South America. Each of these regions has a different situation. In the United States steel demand is currently growing and prices are improving. In Brazil there are problems related to the economy. Maybe in two years or so we will see some improvements here. South America is generally open for imports because most of the countries don’t have a large local steel industry, so we have to compete here with other steel suppliers.

What major activities, efforts or investments are planned by the Gerdau Group to meet the challenges that lie ahead?

Gonҫalves: We want to increase the mechanization of our plants to reduce manpower requirements followed by more automation and process control. In particular, it will be important to increase the degree of automation and robotic solutions in dangerous areas to improve safety.

What do you see as the main areas for further research and development to improve production operations, costs and market opportunities at Gerdau?

Gonҫalves: Solutions for improving overall efficiency and process control would be important. We ourselves don’t have the capacity to do major R&D work in these areas, so a partner is required to develop new technologies and to improve existing ones.

What are the main criteria that you consider when selecting a technology supplier, and which factors do you value most when dealing with business partners?

Gonҫalves: For us it is important to maximize the total lifetime of a plant investment. Committed lifecycle support from a supplier is therefore a key factor. Construction costs are high where we are located, which means that simple and reliable facilities generally offer us the best cost-investment option. A supplier’s reputation and know-how are very important for us.