On March 18, 2014, a new, fully integrated hot rolling and processing facility (HRPF) supplied by Primetals Technologies on a process-turnkey basis was started up at the Brackenridge facility of Allegheny Technologies Incorporated (ATI) in Pennsylvania, USA (Figure 1). The mill is capable of rolling up to 3.5 million t/a of a broad range of highly diversified stainless and carbon steels, specialty metals and electrical steel grades that find use in the aerospace, automotive, defense, petroleum, chemical, construction, mining and power industries, in addition to various medical, food-equipment, machine and cutting-tool applications. The rolling forces are the highest ever to be applied in a hot-strip rolling mill. This article outlines the features and highlights of this worldwide-unique rolling complex.

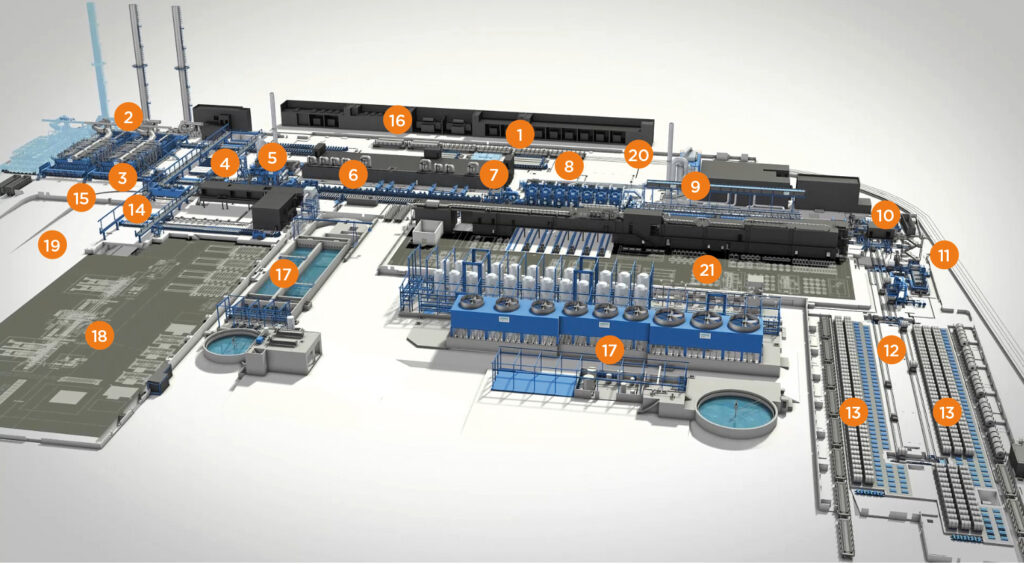

The HRPF project scope for Primetals Technologies included engineering, manufacture of special components, and the supply, installation and commissioning of mechanical equipment as well as electrical and automation systems. The scope of supply covered transfer and handling equipment for slabs and ingots; heating/reheating furnaces; primary and secondary descalers; slab and rotary crop shears; a 4-high reversing roughing stand with an integrated heavy edger; heat-retention Encopanels; a 7-stand, 4-high finishing train; a laminar-cooling section; two Power Coilers with integrated pinch-roll polishers and quick-exchange pinch-roll units; a coil-handling system; integrated sampling, inspection, marking and strapping machines; fume-exhaust systems; and a water- treatment plant. The electrical and automation systems comprised the main and auxiliary motors, drives, instrumentation, basic automation, process automation, the Siloc yard-management system and a manufacturing execution system (MES). The general layout of the HRPF is depicted in Figure 2.

Leading-edge technologies are built into the HRPF to ensure top-class performance and to control key parameters such as thickness, cooling and coiling temperatures through the use of built-in process models and the associated automation-controlled actuators.

2. Walking-beam furnace

3. Slab shear

4. Primary descaler

5. Roughing mill with edger

6. Encopanels, plate pusher and plasma cutter

7. Rotary crop shear and secondary descaler

8. Finishing mill

9. Laminar-cooling section

10. Downcoiler section

11. Coil inspection and heavy-gauge cutter

12. Coil handling

13. Coil yard

14. Manipulator and underground slab ferry

15. Ingot buggy

16. Transformer

17. Water-treatment plant

18. Ingot yard with slab grinder, car-bottom heating systems and induction furnace

19. Soaking pits

20. Hot boxes for heat retention

21. Roll shop

HRPF equipment and systems

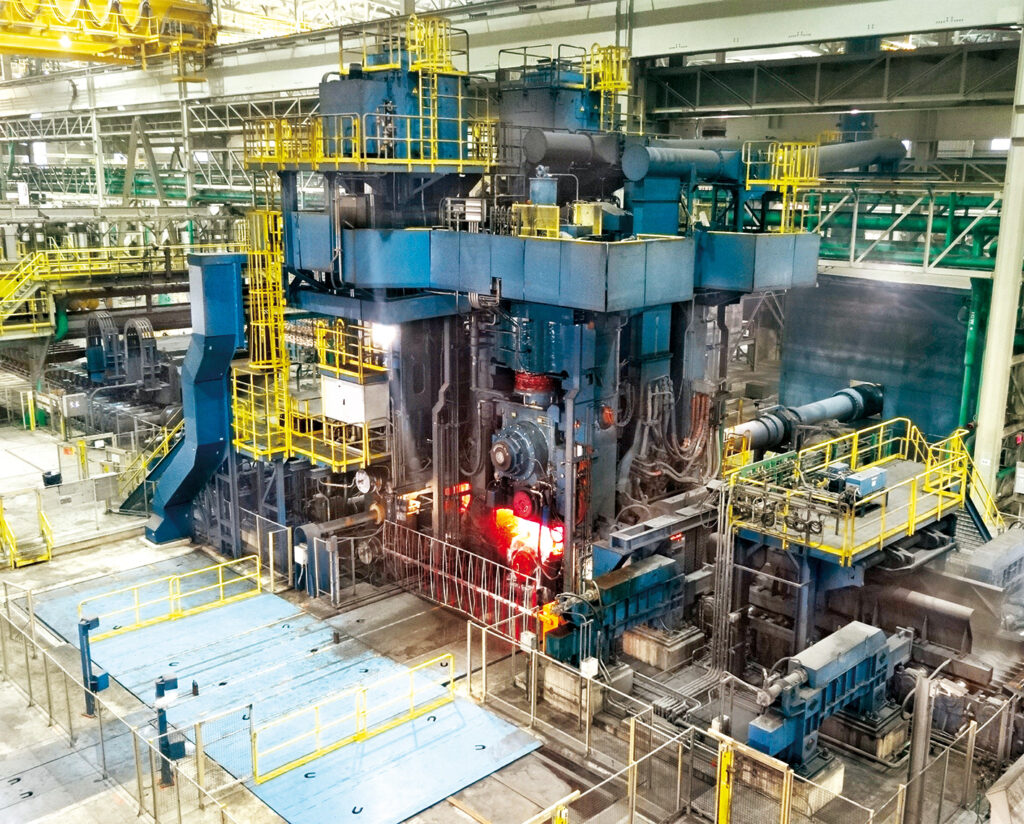

Roughing mill

Following reheating and descaling, the slabs or ingots are initially rolled in the roughing mill (Figure 3), which is equipped with an edger and state-of-the-art twin drives with a motor power of 9.5 MW each. The roughing mill stand is capable of exerting a maximum load of 60 MN. This immense power gives the HRPF the capability and versatility to process and roll the broadest ranges of specialty metals in the industry. Slabs can be processed up to thicknesses of 250 mm (10 inches), at widths up to 2,083 mm (82 inches) and at lengths up to 12,497 mm (492 inches) – allowing a maximum coil weight of up to 40 metric tons to be produced. Ingots can be processed with thicknesses up to 660 mm (26 inches), at widths up to 1,778 mm (70 inches) and at lengths up to 5,080 mm (200 inches). Following roughing, the transfer bar passes on to the finishing mill through an Encopanel-covered section to minimize temperature loss and provide a more uniform finish-rolling temperature.

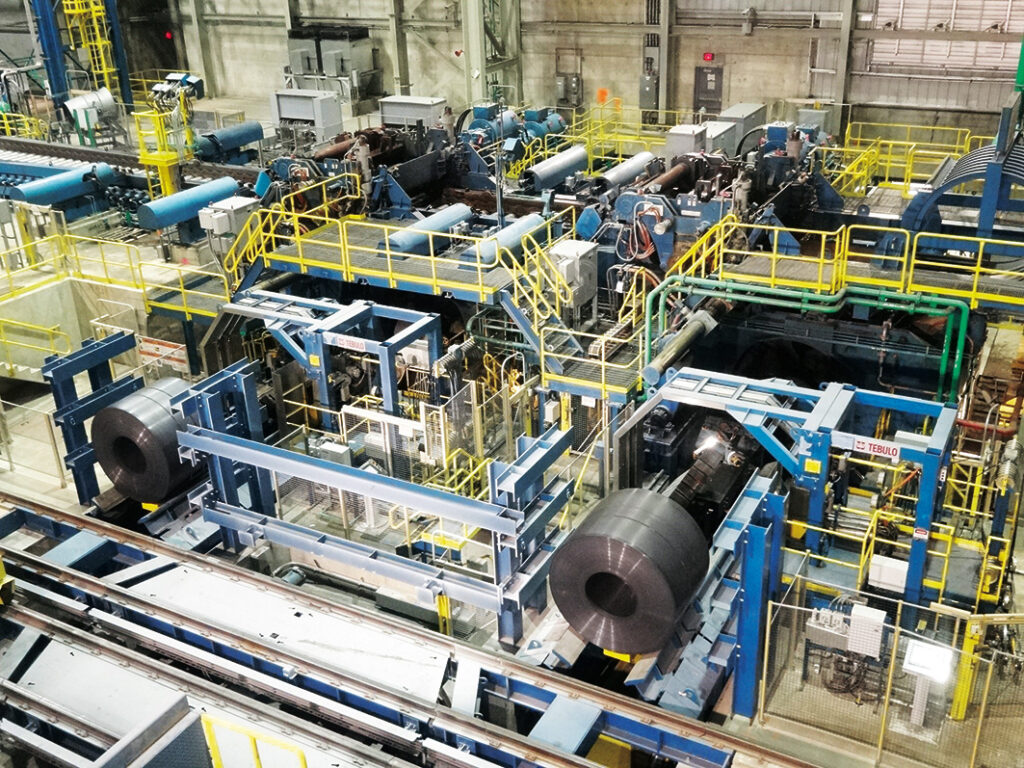

Finishing mill

The finishing mill is designed with seven 4-high stands, each of which is powered by 10 MW drives (Figure 4) and is capable of exerting a mill-stand load of up to 55 MN. Patented technological controls allow the application of long-stroke HAGC (hydraulic automatic gauge control) cylinders for improved operation and maintenance. All stands feature dynamic work-roll cooling that permits defined cooling patterns across the work-roll barrel length to be carried out. Additional systems include interstand cooling, work-roll lubrication, a fume-suppression system, strip cross sprays, entry-guide cooling as well as looper cooling as the basis for optimum process parameters and equipment conditions.

In order to ensure that the highest technological demands are met for rolling ATI’s extremely sophisticated product mix, the mill is furnished with numerous state-of-the-art technological packages. These include SmartCrown rolls installed in the finishing stands, which operate in conjunction with L-type bending blocks and the work-roll shifting system. This technology is a decisive factor for assuring excellent strip profile and flatness control.

Laminar-cooling section

The laminar cooling section comprises 54 top headers and 162 bottom headers that provide a maximum water- flow rate of 20,000 m³/h. The cooling headers are flow-controlled on the basis of calculations from a microstructure target-cooling model. Laminar cooling is split into a fast cooling zone (first 20 top headers) and a normal cooling zone (remaining 34 top headers). Each top header and each group of bottom headers is separately regulated by a flow-control valve. This setup increases the overall flexibility of the cooling system and allows a variety of cooling rates to be applied for exact control of phase transformation, depending on the desired steel grade to be produced.

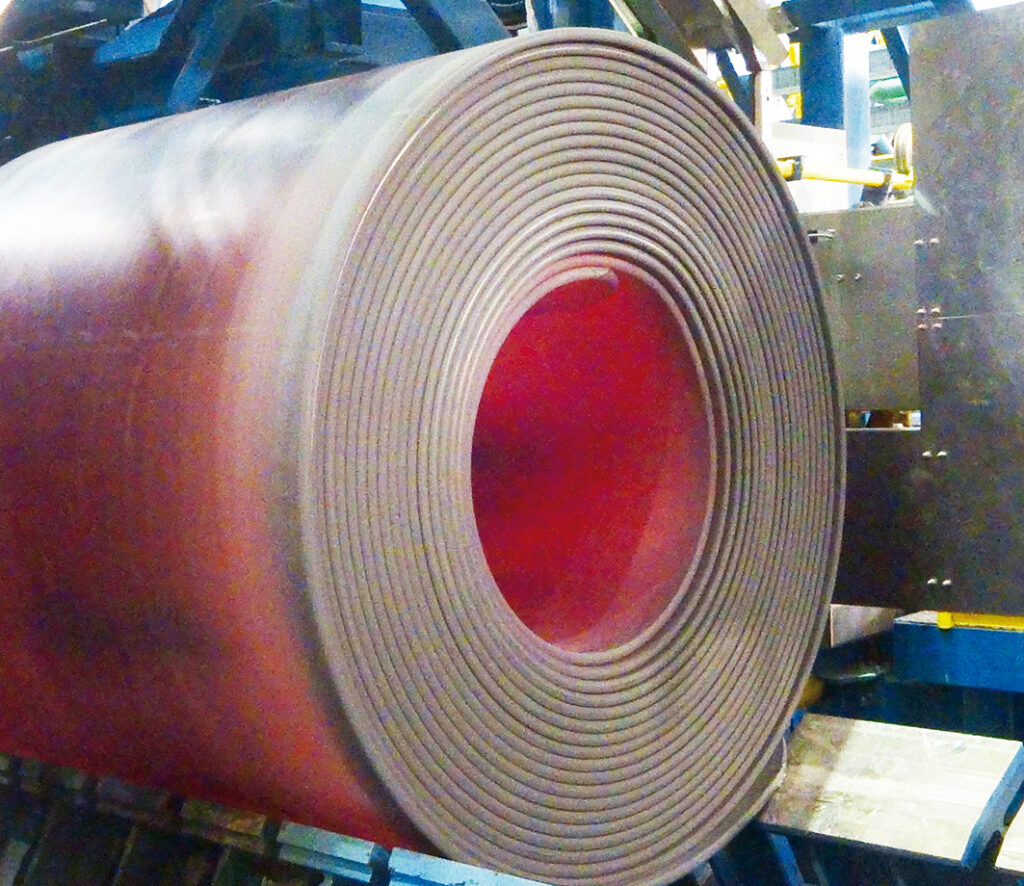

Downcoiler section

Two so-called Power Coilers are installed in the coiling section, which are dimensioned so that they are capable of coiling API X100 pipe-grade material at a thickness of 21.2 mm (0.83 inches) and a width of 1,956 mm (77 inches) or API X80 pipe-grade material with a thickness of 25.4 mm (1 inch) and a width of 2,083 mm (82 inches) – Figures 5 and 6. The Power Coilers are equipped with servohydraulically controlled side guides, pinch-roll units and four wrapper arms. They are also outfitted with pinch-roll polishers, quick-exchange pinch-roll units and coil-springing-prevention devices. The coils are subsequently strapped, weighed, marked and, if required, inspected before they are transferred to the coil yard for subsequent processing or dispatch.

Automation and logistics

The entire facility is controlled from control pulpits positioned at the roughing mill, finishing mill and downcoiler. A complete suite of Level 1 automation systems and sophisticated Level 2 process-optimization systems with integrated tailored process models ensures that nothing is left to chance (Figure 7). Level 2 rolling systems include models for the precise control of rolling parameters; models for monitoring and governing strip temperature, heat transfer and phase transformations; and other models for profile and flatness control, roll bending, roll thermal crown and roll wear, material flow, roll flattening and roll shifting. The cooling section includes models for temperature monitoring and control, heat-transfer and phase transformations. The application of a manufacturing execution system (MES) and a logistics system (Siloc) serve as the basis for record-breaking melting-to-shipping throughput times. These systems enable ATI to operate this exceptional facility at maximum output without the need for a slab yard. Space requirements for the coil yard only had to be designed to store the coil output from a single production shift. Furthermore, the installed automation systems reduced personnel expenditures for the operation of the HRPF. All of these factors support ATI to reduce its managed working capital significantly.

Expanded product mix and rolling capabilities

Following the successful completion of all required performance tests, the final acceptance certificate (FAC) was issued on February 3, 2016. ATI now has at its disposal the capability to offer its sheet and plate customers a significantly expanded range of specialty metals and product dimensions that are unique in the industry. Larger, longer, thicker and wider coils are produced with thinner gauges, superior tolerances, improved surface quality and more consistent mechanical properties. Overall hot-rolling performance has been significantly augmented with the new HRPF as follows:

- Unprecedented short melt-to-shipping lead times

- Reduced manufacturing throughput time

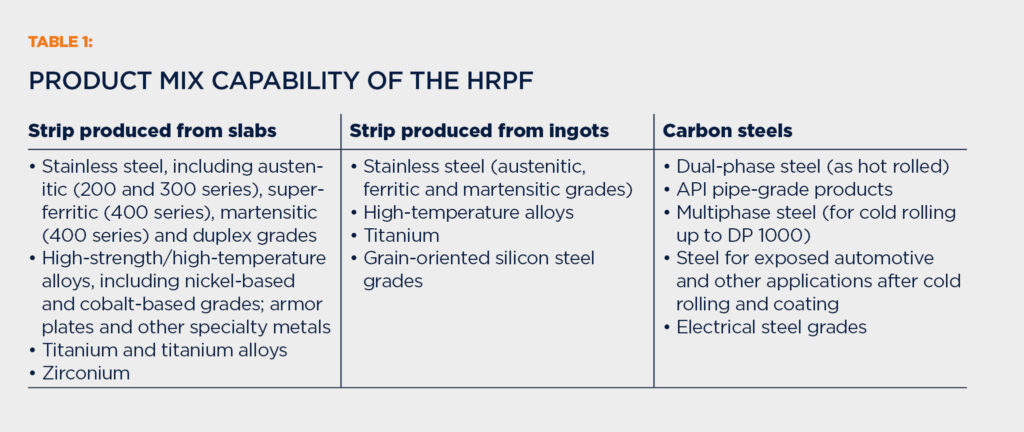

- Production of an incomparably and highly diverse product mix (Table 1 and Figure 8)

- Enhanced capacity to meet customers’ product design needs and increased range of product applications

- Unique capability to offer best-in-class coil geometry

- Rolling of outstanding 1,500 mm to 2,000 mm wide coil and plate products at the lowest and highest gauges in the industry

Outstanding cooperation

The HRPF project represents an outstanding example of a successful cooperation between a market-leading supplier of specialty metals and a metallurgical plant builder. The installed power, size and advanced technology of the mill, combined with decades of operational expertise, allow ATI to fully meet the most demanding customer requirements in a highly efficient and productive manner.