This post is also available in: 简体中文 (Chinese (Simplified))

The need to reduce ironmaking costs, increase raw material and operational flexibility, and fulfill ever-stricter environmental regulations count among the decisive reasons behind the co-development of the FINEX® (hereinafter written as Finex) process by the Korean steel producer Posco and Primetals Technologies. Starting with a 600,000 t/a demonstration plant, Finex technology has evolved to a production facility with an annual output of approximately 2 million tons. This article outlines the operational and production benefits of the Finex F-2.0M facility that was put into operation at the Pohang steelworks of Posco more than two years ago.

Evolution of the Finex process

The first commercial Finex plant (F-1.5M model) was designed with an annual hot-metal production capacity of 1.5 million tons. Started up in April 2007, its economic feasibility as an alternative ironmaking process to the blast furnace could be quickly confirmed (Figure 2). The blow-in of the F-2.0M (2 million t/a) Finex plant in January 2014 and successful production of hot metal since that time has proven that the Finex process is a viable and competitive alternative to the conventional blast furnace ironmaking route with coking and sintering plants.

Design modifications of the Finex F-2.0M plant

The design of the third-generation Finex plant features simplified plant construction and a lower overall weight compared to the F-1.5M plant concept. The following main design and process improvements were implemented:

- Pneumatic ore charging to a 3-stage (as opposed to the previous 4-stage) fluidized-bed reactor system resulting in a 30% lower building height

- Simplified design of the hot-compacted iron (HCI) plant for the compacting of direct-reduced ore and additives

- Installation of a dry-dedusting system in the HCI plant

- Elimination of the HCI bin and associated top-gas system in the melter-gasifier tower

- Installation of a center-positioned dynamic Gimbal Top distribution system at the top of the melter gasifier for the uniform charging of HCI, coal and additives into the melter gasifier

With these design and process improvements, the overall construction weight of the Finex F-2.0M facility was reduced by approximately 9% compared to the Finex F-1.5M plant – with no increase in the overall plant footprint. During the construction period of 31 months from groundbreaking to blow-in, roughly 77,000 tons of steel structure, equipment, piping and refractories were installed. Around 1,600 km of cables were laid and some 16,000 I/O (input/output) signal checks were carried out.

- Direct utilization of low-grade and low-cost iron ore fines as the oxide feed

- Direct use of non-coking coals as the reductant

- Favorable economics with respect to capex and opex (approximately 12% lower opex compared to a new blast furnace of similar capacity)

- Environmental benefits, including reduced emissions of NOx and SOx by 90% and 95%, respectively, compared to the conventional blast furnace route

- Flexibility in the selection of raw materials (e.g., use of ores with higher Al₂O₃ contents)

- Production of hot metal in a quality that is identical to blast-furnace hot metal

- Release of a valuable export gas for other industrial uses such as for power generation, DRI production or the manufacture of chemical products

- Brownfield installation within an integrated steelworks offers synergies with existing blast furnaces that include the charging of undersized coke and sinter fines directly to the Finex process

First two years of hot-metal production with the Finex F-2.0M plant

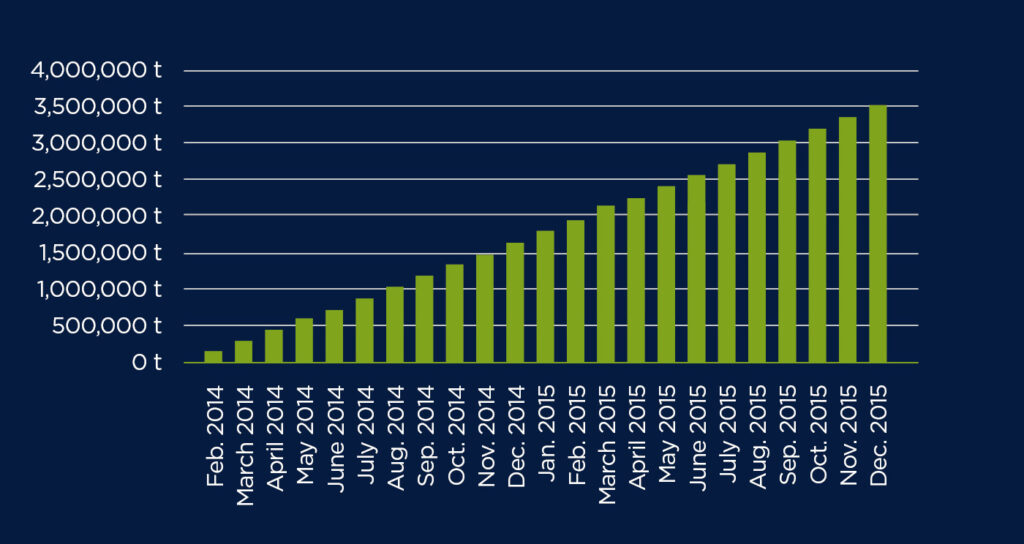

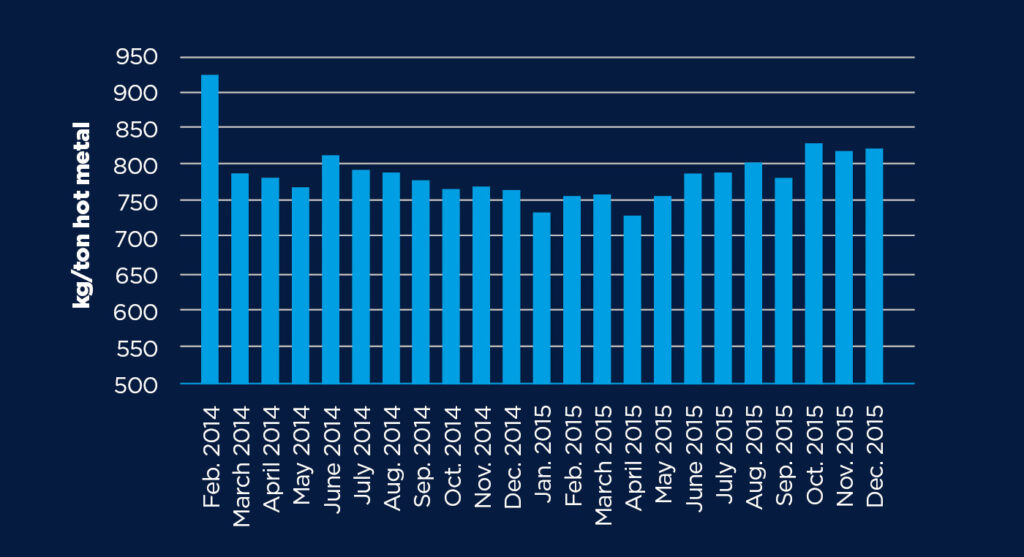

Following the plant start-up in January 2014, process and production parameters were optimized and production was gradually ramped up to design capacity. Productivity of the F-2.0M Finex plant reached its target value of 5,760 t/d in April 2014. Since then, all other key operational targets were met and a plant availability of >95% was achieved during the first two years of production operations. Figure 3 shows the cumulative hot-metal production of the F-2.0M Finex plant during a 23-month period that extended from February 2014 to the end of December 2015. Figure 4 depicts the specific fuel consumption during the same period, and Table 1 shows typical consumption figures of the Finex F-2.0M plant with an annual hot-metal production of 2 million t/a.

Planned energy savings and environmental system installations

Posco’s Finex F-2.0M plant will be additionally equipped with a waste-heat recovery system, a dry-dedusting unit and a top-gas pressure-recovery turbine (TRT) with the objective to further enhance overall energy efficiency and environmental compatibility of this ironmaking facility. Start-up and commissioning is scheduled to commence in May 2017.

A bright outlook

Finex is the world’s only hot-metal production process that is based on the direct use of iron ore fines and non-coking coal. As proven at the Pohang steelworks of the Korean steel producer Posco, Finex represents a highly competitive alternative to the conventional blast furnace route and offers producers decisive environmental advantages. Since the introduction of this technology in 2003, a total of more than 22 million tons of hot metal have been tapped from all Finex plant variants as of the end of April 2016. Currently, new Finex plant installations are under consideration for iron- and steelworks in China, India and Iran.

Iron ore consumption: 1,550–1,650 kg/t hot metal

Fuel rate: 750–800 kg/t hot metal (including 50–100 kg coke)

Additive consumption: 250 kg/t hot metal

Oxygen consumption: 500–550 Nm³/t hot metal*

Export gas quantity: 335,000 Nm³/h

Net calorific value of export gas: 5,500–6,250 kJ/Nm³

Electrical power consumption: 220 kWh/t hot metal

Nitrogen: 400–450 Nm³/t hot metal

Make-up water: 1–1.5 m³/t hot metal

*Nm3 stands for normal cubic meter