This post is also available in: 简体中文 (Chinese (Simplified))

Power Cooling is a state-of-the-art, innovative cooling solution for both new and existing hot-strip mills, and one of the most sought- after products from Primetals Technologies. It enables producers to manufacture steel grades previously unachievable for them, such as line pipe and high-strength low-alloy steels. It is also a considerable cost-saver, as it lessens the need for alloying agents over the course of the production process. Power Cooling is typically installed at the beginning of a cooling line. When added as an upgrade to an existing plant, it requires only a very short plant downtime.

When China’s Wuhan Iron and Steel Co. approached Primetals Technologies for what would become an exemplary installation of Power Cooling, the steel producer’s objective was clear: Wuhan’s goal was to upgrade the existing laminar-cooling line in its 2,250 mm hot-strip mill so that the product mix could be shifted closer toward high-end steel grades such as high-strength low-alloy, dual-phase and line-pipe steels. Instrumental to this advancement was that the plant’s cooling intensity in both the early and the late cooling phases would be significantly increased.

A Custom-Tailored Setup

During the planning stage, Primetals Technologies proposed to install additional high-capacity “turbo-laminar” cooling headers in the rear section of the cooling line, which would allow the cost-efficient production of as-hot-rolled, multi-phase steel grades. Furthermore, a laser-type speed gauge was added to the cooling line so that the speed control accuracy could be increased. This measure was expected to especially have a positive effect on the temperature accuracy of those strips that are shorter than the distance between the last finishing mill stand and the downcoiler.

To facilitate an accurate tuning of the new cooling process model, intermediate temperature measurements proved necessary, especially in those instances where the mill produced strip through the application of an interrupted-cooling strategy. Together with the customer, the project team of Primetals Technologies decided to remove eight of the existing top headers and 24 bottom headers to create the gap required for making these measurements.

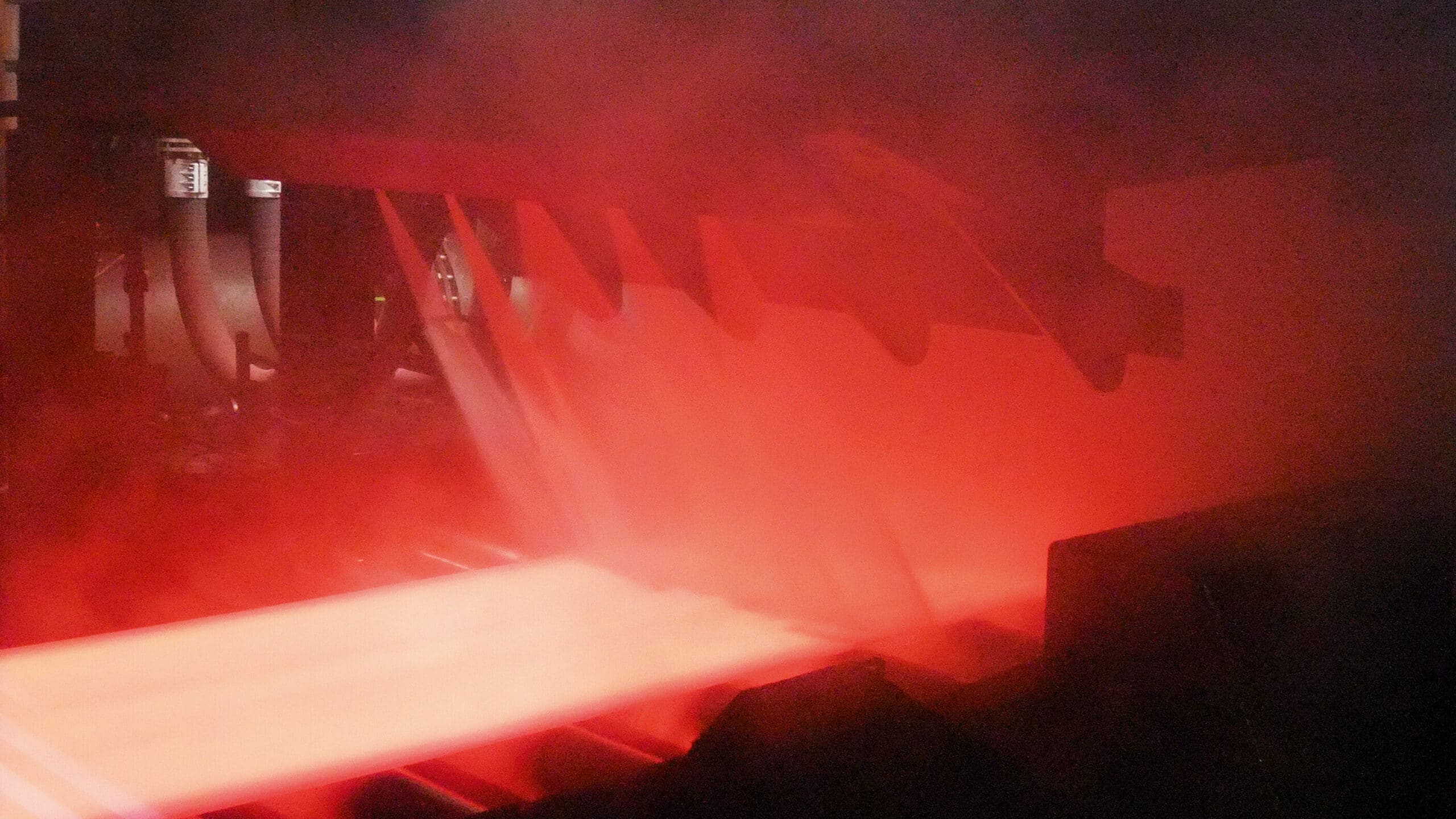

Power Cooling Comes Alive

The first 16 laminar-cooling header sets, with each set comprising one top and three bottom headers, were replaced by 18 sets of the far more effective Power Cooling headers. Each of these header sets consists of two top headers and two bottom headers. After the upgrade, the complete Power Cooling zone featured a total maximum flow rate of approximately 14,000 m3/h. This enabled extremely high cooling rates during the early cooling phase to be achieved in order to meet the demanding requirements of the production process when the most advanced high-strength steel grades are manufactured.

The flow rate of the new Power Cooling headers is widely adjustable, which thus permits an exceptionally broad range of cooling rates to be applied for the production of the desired steel grade. Applicable cooling rates can extend from mild up to intensive, depending on the steel grade specifications and quality and gauge parameters. For certain standard products that command a very specific cooling strategy, the previously existing laminar-cooling headers can be used in parallel with the new Power Cooling setup.

A Comprehensive Upgrade

As part of the upgrade, a new overhead water tank was installed. It was designed to supply water to the Power Cooling headers, which can be operated similarly to standard laminar-cooling headers that rely on gravity to build up the necessary pressure. When higher flow rates are called for, the water is pressurized by frequency-controlled booster pumps. This operational concept combines the most advanced high-capacity cooling technology with the most economic production costs. To ensure the most efficient cooling possible in all situations, the cooling system offers an additional operation mode called “quasi-laminar” cooling. In this mode, the pumps run at very low speeds so that a switchover to “pressure-cooling mode” can be facilitated within less than a second.

In order to increase the maximum cooling rate during the second stage of cooling of “as-hot-rolled multi-phase steel grades,” a number of turbo-laminar-cooling headers were installed in front of the existing trimming zone. These headers work like standard laminar-cooling headers and are fed from the new overhead tank, but can provide significantly higher flow rates due to their special design. In order to offer maximum flexibility in terms of cooling rates, as required for different products, all top headers and each corresponding group of three bottom headers are flow-controlled.

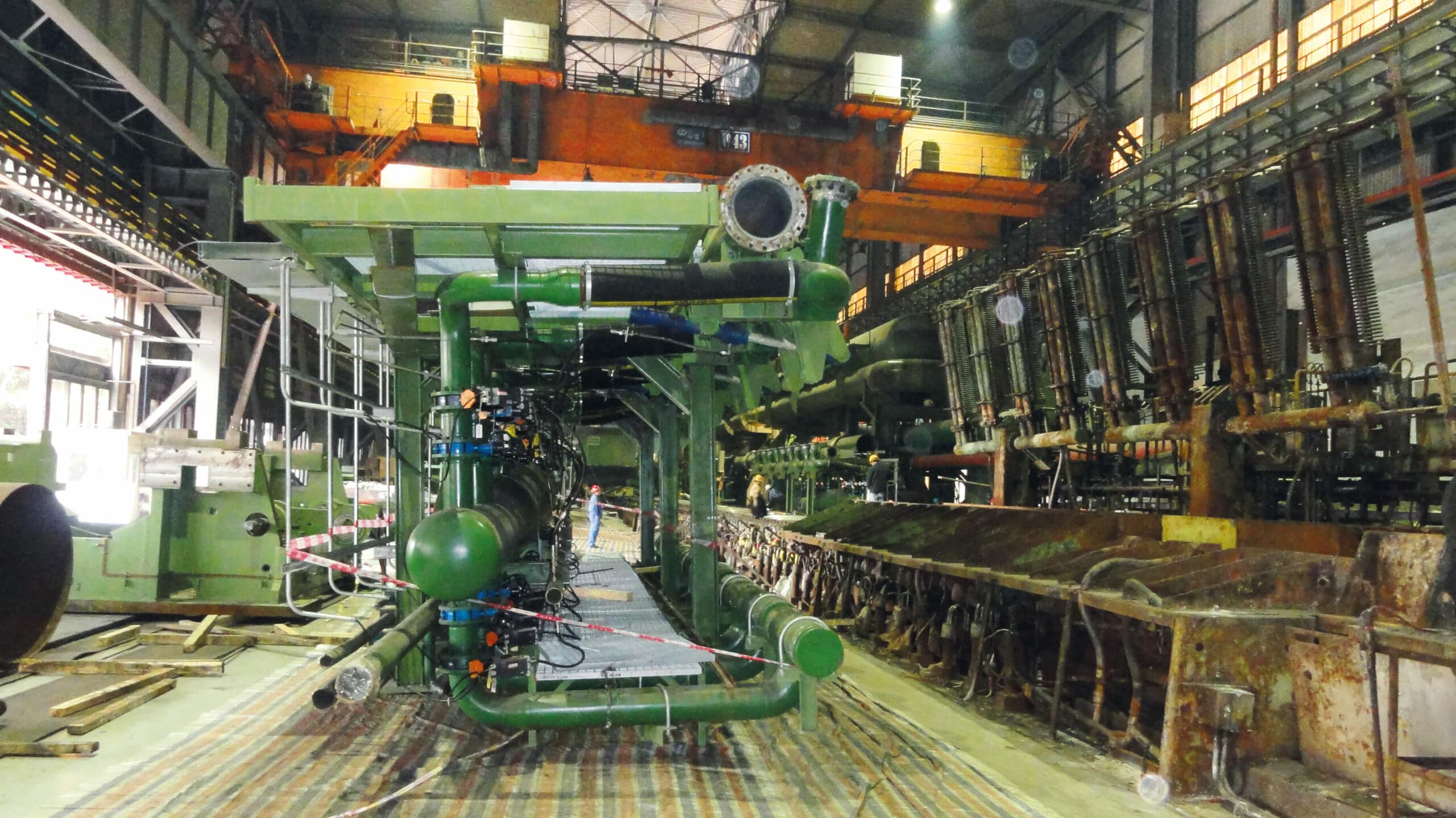

Streamlined Installation

To minimize the shutdown time that would be imposed by the installation, all new equipment was preassembled on site and into units that could be lifted and moved into position using an overhead crane. This was done directly after the existing equipment had been removed. The upgrade also entailed the replacement of the roller table section in the Power Cooling area to ensure a proper drainage of the water on both the top and the bottom side of the strip. The Power Cooling headers were pre-tested at the manufacturer’s site to verify that all requirements would be fully met immediately after the start-up of the cooling line. Due to the highly detailed planning and streamlined execution that Primetals Technologies provided over the duration of the installation, the total plant downtime was kept to just 15 days. Future installations of Power Cooling are expected to be completed in an even shorter timeframe.