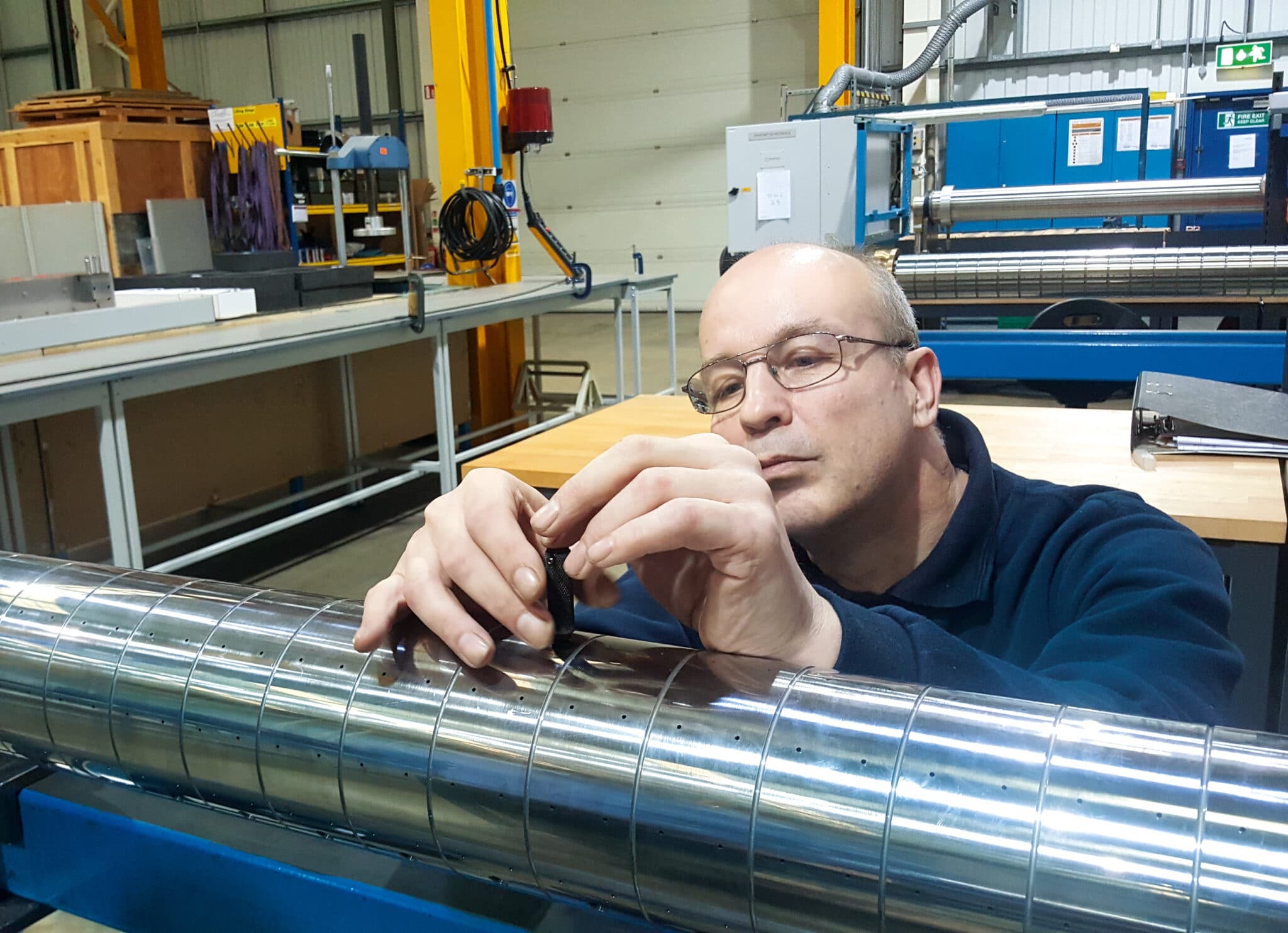

The Air-Bearing ShapeMeter of Primetals Technologies accurately measures the shape of rolled metal sheet and foil material (Aluminum and other metals). It provides continuous, high-accuracy readings with fast signal-response rates even at low rolling speeds. Thanks to its modular construction, the Air-Bearing ShapeMeter can be adapted to almost any application without compromising its full operating capability. The core of the instrument is a roll comprised of hardened, precision-ground rotors, which are supported by an air film on a stationary, stainless-steel arbor. Each rotor is supplied with air by an array of jets that are connected to a common plenum chamber in the arbor’s center. This design results in low-inertia rotating elements that exhibit the minimal frictional resistance typical of air bearings. The need for helper drives is eliminated.

The operating principle of the Air-Bearing ShapeMeter is straightforward: the pressure differential between the top and bottom of the inside of each bearing is proportional to the load applied to the rotor. It is therefore possible to calculate the tension at each rotor position across the width of the rolled metal sheet. As a result, the Air-Bearing ShapeMeter can accumulate enough data to determine a profile of the stress distribution—a “shape”—of the sheet. Every differential-pressure output is measured by a high-integrity pneumatic transducer, which is located remotely in the transducer housing attached to the end of the arbor through an armored signal cord. With more than 600 installations worldwide, the Air-Bearing ShapeMeter has a track record of excellence going back 40 years. Its high accuracy, robust construction, modular design, low maintenance needs, and strikingly positive impact on end-product quality have convinced many customers of Primetals Technologies to trust its readings for optimal rolling operation.