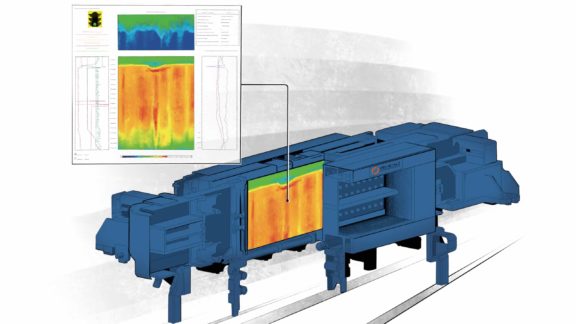

The Automatic Thermocouple Checker is a computer-aided tool designed to test the quality of a thermocouple installation. The test involves heating the copper plate in the same position and with exactly the same intensity each time so that it is impossible to damage the copper plate.

The device delivers highly accurate temperature measurements with deviations within a range of only 0.1°C. Any bad contact between the thermocouple and the copper plate can also be detected. The automatic, repeatable heating of thermocouples allows the quality of thermocouple installations to be markedly improved, while keeping the exchange of molds from bad thermocouples to a minimum.

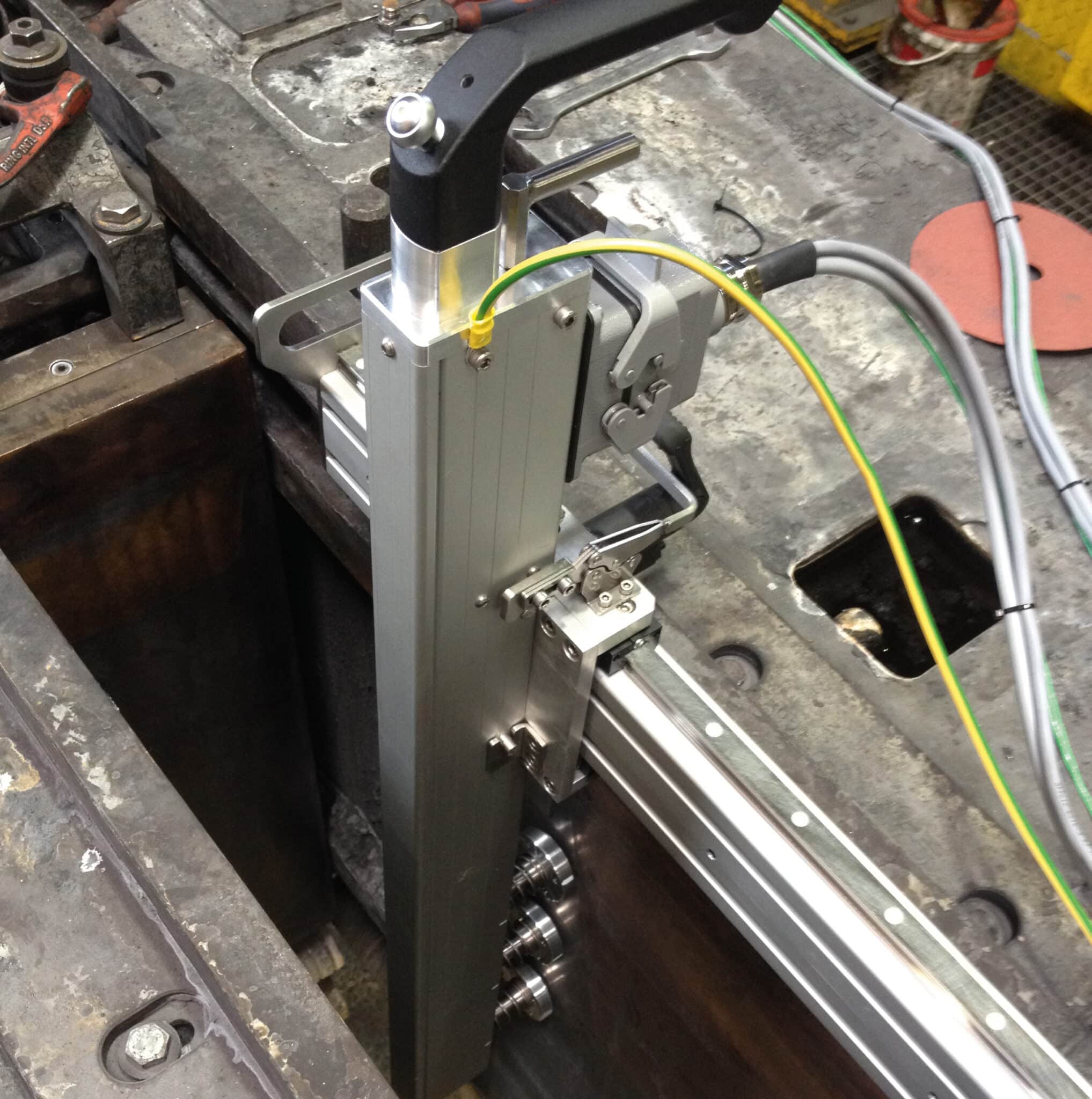

The Automatic Thermocouple Checker is delivered as a transportable unit that is connected to standard thermocouple connectors. It is suitable for testing the integrity of narrow faces as well as broad faces and can be used to measure either single-mold plates (maintenance area) or mold plates at the assembled mold (in the machine). The measuring arm is positioned manually by the operator to a predefined (lockable) thermocouple column requested by the software. In a fully automatic procedure, the thermocouples in a column are heated one after another, and the temperature reaction is evaluated. Once an entire copper plate has been checked, any thermocouples with bad contacts are flagged and a report is generated.

The Automatic Thermocouple Checker eliminates measurement errors as a result of incorrect heating positions and guarantees the optimum performance of thermocouples. Consequently, maintenance work can also be kept to a minimum and quality management improved based on the recorded data.