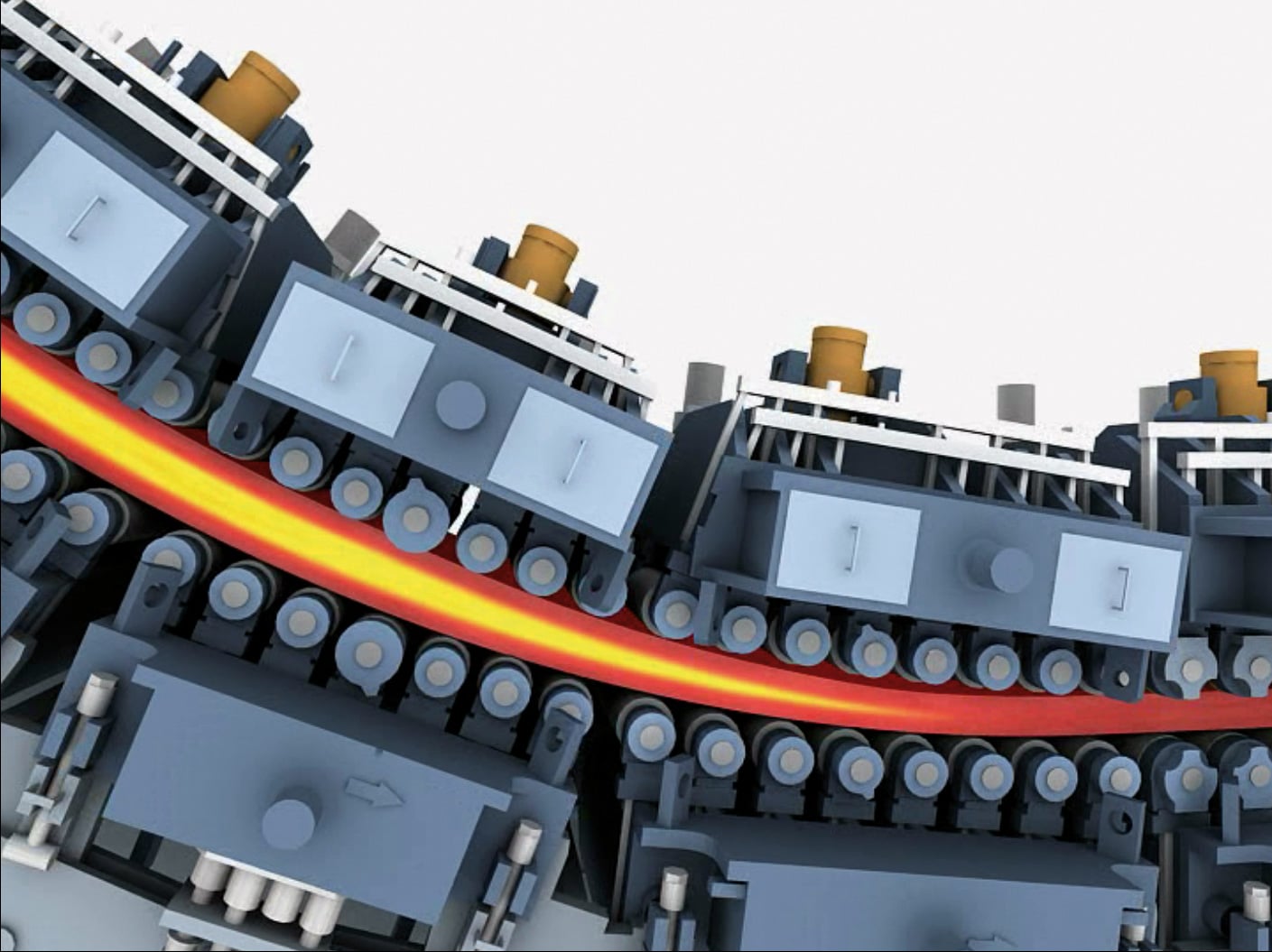

DynaGap Soft Reduction 3D (DynaGap 3D) is a sophisticated process model that allows for dynamic roll-gap changes in slab and bloom casters. Working in combination with remote adjustable segment types such as Smart, Single Roll DynaGap (SRD), and Withdrawal Straightening Unit (WSU), roller gaps can be adjusted to perform strand-thickness changes, eliminate centerline segregation, and reduce porosity for substantially improved internal strand quality.

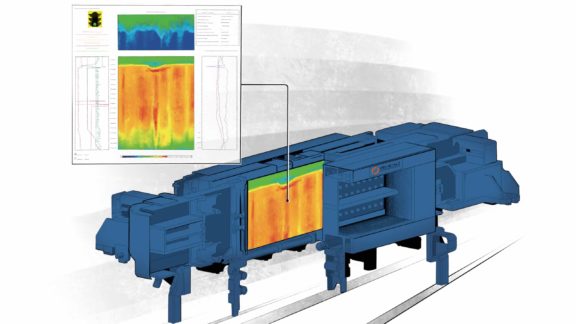

On the basis of detailed online information provided by the Dynacs 3D thermal-tracking model that includes steel shrinkage, DynaGap 3D dynamically calculates the required set points of the roll gap. Supervision of roll engagement, depending on the state of strand solidification and the calculated strand-thickness profile, is decisive for ensuring precise roll adjustments and outstanding product quality. Optimized roll engagement also prevents excessive forces from being exerted on the strand and reduces unnecessary roll wear.

Highly accurate control of the roller gaps also allows additional casting strategies to be implemented that include liquid-core reduction for high-speed casting, extended soft reduction, and also hard reduction to

further reduce porosity for additional product quality improvements. Thanks to its modular setup and design, this process model can be used on existing casters with basic automation systems supplied by third parties.

Number of references: installed in more than 50 casters since the introduction of this process model in 2011; 11 additional projects will be implemented in 2018 and 2019.