The Orbis+ is a rotating gauge designed to continually measure properties of hot steel in rod and bar rolling mills such as the diameter, and to pass on this information to the automation system. The system includes an in-line gauge head capable of withstanding the harsh environment of a rolling mill, as well as an operator workstation where the product dimensions and profile are displayed on a user-configurable screen in numeric or graphical form.

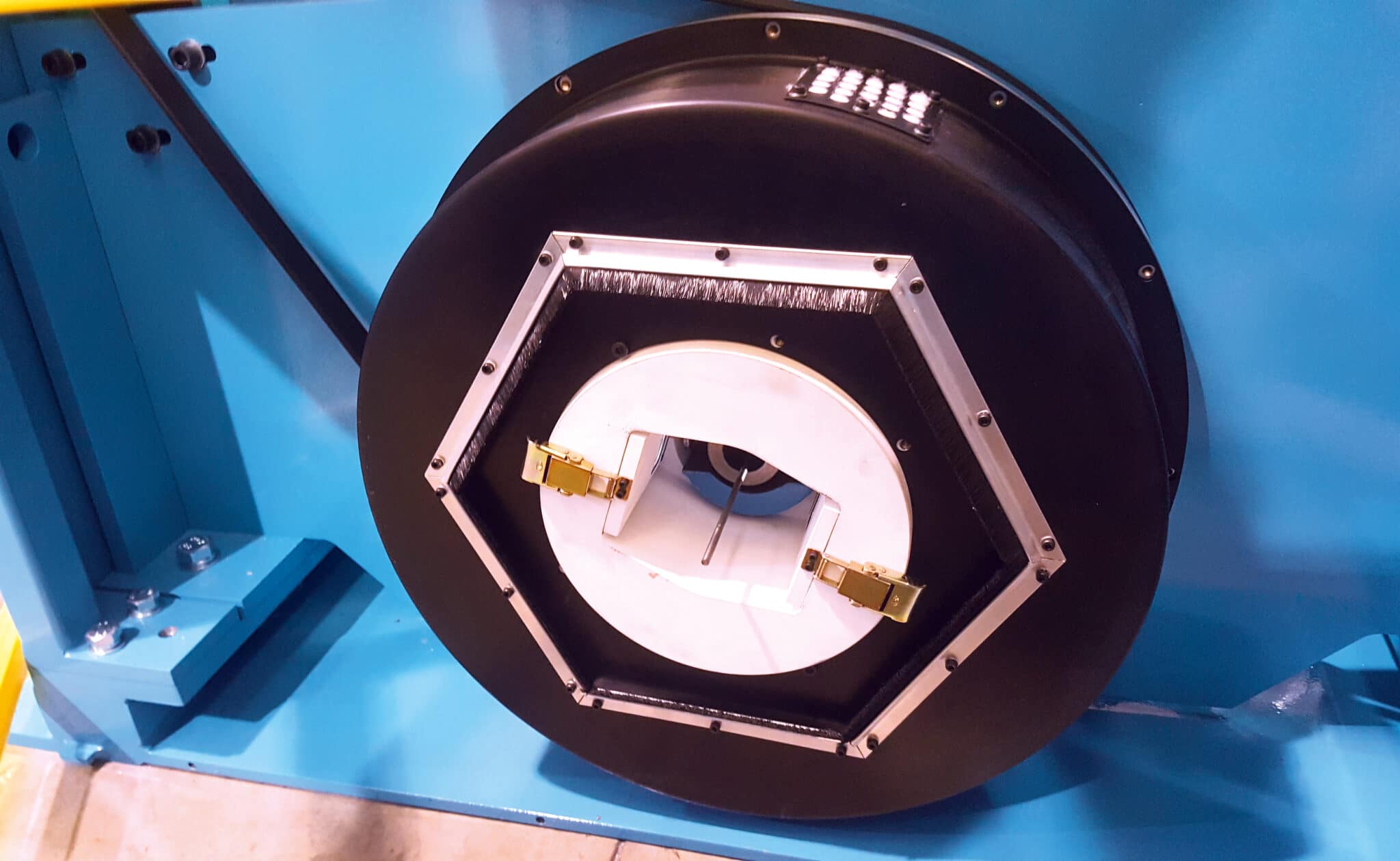

Fully rotating optics enable the gauge to measure and display the dimensions of round and non-round shapes regardless of product orientation. The optical system is mounted on a rotating assembly comprising a collimated light source and a dual- or single-line scan camera, and is sealed from the mill environment. The back light is a collimated source which utilizes an LED and lens assembly to produce a collimated beam across the field of view. As the product passes through the gauge, it obscures the light path, causing a shadow to be seen by the line-scan camera, and this is converted into an absolute measurement by a simple calibration algorithm. An optional pyrometer can be used to provide the product temperature; this input is used to convert the hot dimensions into cold-corrected measurements before they are displayed on the operator screen, allowing rapid judgments to be made about any necessary mill adjustments.

The graphical area is in the form of a polar plot, meaning that any bar defects (overfill, underfill, roll cross, etc.) are magnified to enable the operator to immediately identify potential problems in the rolling process. With 200 references installed to date, the Orbis+ has evolved to keep pace with technological advances in computing power and optical equipment while maintaining backward compatibility to ensure a long service life.