As one of the pioneers of continuous casting technology—a legacy extending back to the 1960s—Primetals Technologies has always been the leader in the development and implementation of sophisticated process models geared toward maximizing operational efficiency and the quality of the cast products. As far back as the 1970s, Voest-Alpine Industrieanlagenbau (VAI), a predecessor company of Primetals Technologies, introduced complex nonlinear models for evaluating strand mechanics such as bulging and material creep at high temperatures. Results of these investigations led to the application of many of the process and machine design features that Primetals Technologies still incorporates into its casting machines today.

The use of advanced process models in continuous casting remains indispensable today to meet new challenges arising from changing and increasingly difficult market requirements. The models also help to satisfy the need for new and special steel grades for ever-demanding downstream applications. Primetals Technologies therefore continues to drive innovation in this area, especially by offering a complete range of expert technological packages and models that cover all aspects of the casting process—from the casting platform to the strand run-out area.

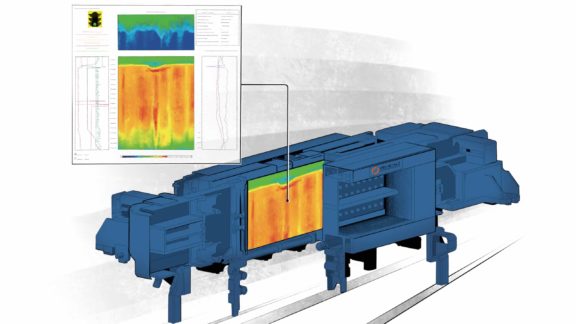

This capability is impressively demonstrated by recent advancements in caster-automation solutions with the introduction of the DynaPhase, Dynacs 3D, and DynaGap Soft Reduction 3D models. This suite of dynamic secondary cooling and soft-reduction packages takes into account thermodynamic effects such as steel shrinkage and phase transitions, thereby significantly contributing to impressive quality improvements during the strand-solidification phase.

All process models from Primetals Technologies are being increasingly integrated with each other to take operating efficiency and product quality to the maximum level. This not only eases the work of the operator but also ensures that customers will have at their disposal the tools and capabilities to thrive and excel in their respective markets.