Selecting the proper casting speed in continuous casting is critically important for the productivity of a caster and the quality it produces. Many factors and requirements have to be considered when choosing the right casting speed: superheat, steel-grade requirements, quality, safety, machine limits, and other production aspects. In many instances, these requirements are at odds or effectively contradict one another; increasing production, for example, calls for higher casting speeds while safety requirements demand lower speeds.

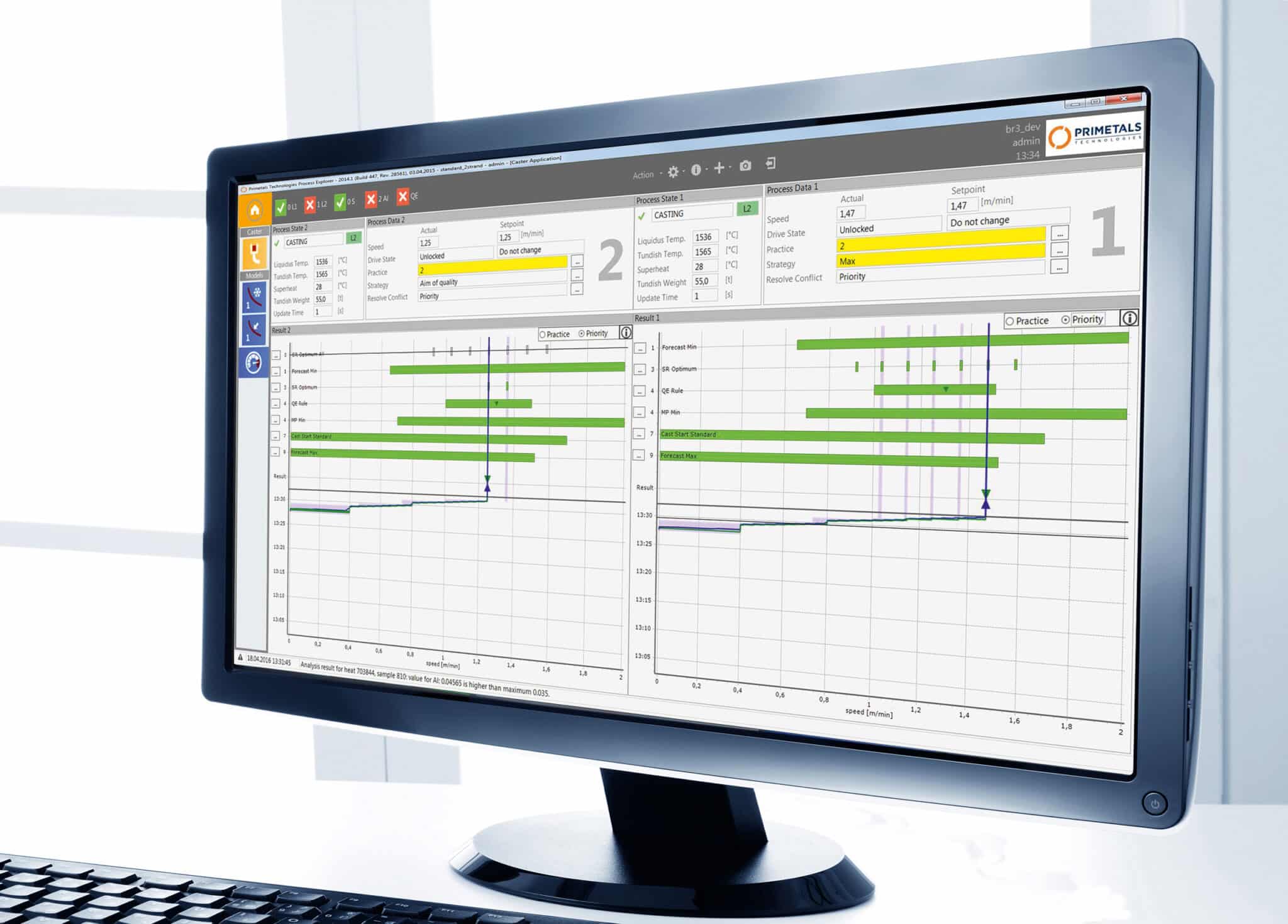

Speed Expert from Primetals Technologies was engineered to take all of these requirements into account and find the optimum balance between them in any given casting situation. It is based on a set of rules—one for each requirement relating to casting speed. Each rule defines the ranges of speed needed to satisfy the appropriate requirement. Rules can also be assigned priorities—if two rules yield contradictory requirements on casting speed, the rule with the lower priority is ignored. Speed Expert then determines the intersection of suitable speed ranges and makes a selection based on a predefined strategy.

Depending on the situation, this strategy may be to maximize speed within the possibilities, to aim for a particular speed, or to avoid any speed changes as long as all requirements are met. In continuous casters that apply soft reduction prior to solidification of the strand, Speed Expert will set the casting speed in such a way that the soft reduction process is completed right at the end of a movable segment. Most remarkably, the system can determine the casting speed necessary to achieve this online during a casting sequence.

Since its introduction in 2015, Primetals Technologies has added eight references for Speed Expert.