This post is also available in: 简体中文 (Chinese (Simplified))

In an effort to further increase the production quality of advanced steel grades at thyssenkrupp’s Duisburg plant in Germany, the engineers of Primetals Technologies have devised a groundbreaking strip-steering method for the hot-rolling stage. This new solution was created in close collaboration with both thyssenkrupp Steel Europe and Johannes Kepler Universität Linz, Austria, and uses custom-built optical sensors in conjunction with an elaborate strip-threading, strip-guidance, and strip tail-out control system. Following conclusive results during the testing phase—particularly in terms of cobble rate and thickness wedge quality—, thyssenkrupp decided to make the technology an integral part of its regular production setup.

Prompted by the rising demand for high-quality strip, the steel industry has begun to use recent advances in control theory, measuring techniques, and machinery equipment to improve production capacity, efficiency, and product quality. The main quality parameters of the rolled strip are the dimensional tolerances of the material, essentially the strip’s thickness and width tolerance, shape, and flatness.

Usually, the shape (i.e. the thickness profile) of the rolled material is first set by the process automation system and then more finely adjusted in the hot-strip mill. The downstream stages are then focused on maintaining the shape and controlling the flatness of the strip. Any change in shape over the length of the strip can cause strip-run and flatness problems. Therefore, it is crucial that the produced strip exhibits a constant shape over the full length.

Another challenge facing plant operators involves preventing the build-up of camber, which can arise from numerous uncontrollable factors (temperature profile, non-uniform thickness profile, etc.). Since the occurrence of camber can cause process interruption and even equipment damage, solutions geared towards counteracting camber build-up are highly sought after in the industry.

Controlling the shape

The main actuators for controlling the shape in the hot-strip mill are the leveling and bending of the work rolls. Leveling is used to influence the thickness wedge, whereas work-roll bending and shifting affects the strip’s thickness profile. However, for strip that is not under tension, changing the leveling of the work rolls determines whether or not there is camber build-up.

The strip-steering control solution developed by Primetals Technologies in collaboration with its partner thyssenkrupp uses Primetals Technologies’ latest vision-based measuring equipment in combination with advanced control technology for automatic threading, in-bar control, and thread-out. The new control solution’s main targets are to improve mill availability and increase productivity by reducing the cobble rate. An additional goal is to increase the quality of the material in respect of the thickness wedge.

Custom-designed sensors

Reliable sensors are essential to any dependable control system. In the finishing-mill section of a hot-strip mill, the environment is heavily impacted by dust and cooling water, which puts substantial strain on sensor operation. Additionally, the strip surface is affected by unpredictable scale spots and temperature variations, which mostly affect the head and tail end but also the edge regions over the full length of the strip. All of these factors make it exceptionally difficult to utilize any sensors close to the strip in the hot-mill environment.

To meet these challenges, Primetals Technologies chose to install a highly specific optical sensor that would be able to withstand the harsh surroundings. This type of device combines camber and centerline-measuring techniques and can simultaneously assess strip width. The advantages of this method are the low number of components, the simple arrangement, and the sufficiently large distance between strip and sensor. Thanks to its operating principle, this sensor ensures high reliability combined with almost zero maintenance.

The engineers of Primetals Technologies decided to use a specific optical sensor (left photo) to obtain the strip data necessary for the new control system. Placement is equally important as the sensor itself: all involved sensors are positioned on top of their respective stands, which protects the measuring devices from the harsh steel-mill environment. The schematic above illustrates the sensor arrangement, with the blue cones of light indicating the sensors’ measuring area.

Two sets of controllers

Since the hot-rolling process needs to be controlled differently depending on whether or not the strip is under tension, two sets of controllers—each with their own particular objective—had to be developed.

The strip-threading control regulates strip threading at the first three stands and relies on strip-position measurements taken by the vision-based measuring equipment, which is located after each of the stands. Its purpose is to support the automatic threading of the strip from one stand to the next with a nonlinear model that describes the movement of the strip at the time it is threaded. This model, the simulation environment, and the respective controller were developed in cooperation with Johannes Kepler University in Linz, Austria.

The goal of automatic strip threading is to prevent camber build-up by introducing a combination of measures, namely the prevention of wedge change and wedge reversion over the length of the strip; adherence to a maximum leveling value; keeping the strip-head position within the operating width of the side guides; and consistent performance in conjunction with all possible material grades, at all temperatures, and for all thicknesses.

Strip-STEERING Control

The second control handles the strip when it is under tension. The objective of the control is to maintain a parallel-loaded roll gap so that no wedge is formed even under asymmetric rolling conditions. The traditional solution is to level the work rolls of the mill stand according to the measured differential roll force multiplied by a constant differential stand modulus. Without camber control in the roughing mill of the hot-strip mill, the shape of the transfer bars is inconsistent, and there is the possibility that lateral movement might occur in the finishing-mill section.

There are several factors that influence wedge thickness, but the effect is dominated by the material’s lateral movement. When strip is rolled off-center in the roll stand, it undergoes asymmetrical reduction to shape the roll-gap profile, which results from thermal crown and roll wear but also from gap actuators (shifting, bending, pair-cross), including roll grinding. Therefore, the feed-forward pathway, including the lateral displacement of the strip, was added to the closed loop between the differential roll force and the amount of leveling. With active feed-forward control, the lateral displacement of the strip is measured and accounted for—before it can affect the system and create a disturbance.

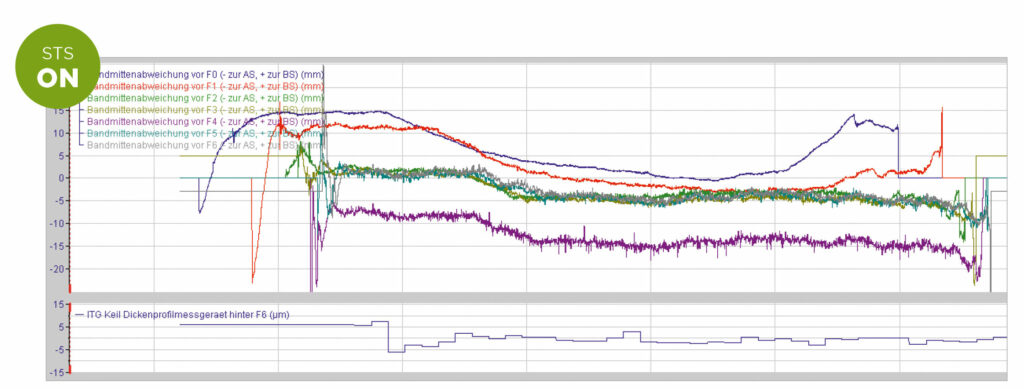

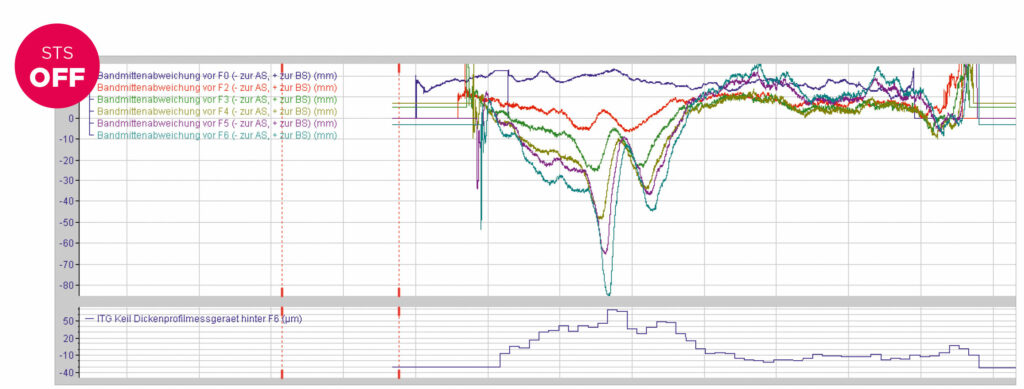

The figures shown in the graphs above compare data from a strip rolled where strip steering control is active (left) and inactive (right). The upper parts of the charts show the lateral displacement of the strip at each roll stand. Without steering control, there is a strong correlation between lateral displacement and the evolved thickness wedge after the finishing mill section outlined at the bottom of the charts. This is not the case when steering control is active, and even where lateral displacement of the strip occurs, there is no effect on the rolled product’s thickness wedge thanks to the strip-steering control.

Excellent results

In 2016, the strip-steering control system was implemented and tested at thyssenkrupp’s Duisburg-based WBW1 plant. Initial tests were performed for common rolled products, subsequent tests targeted special steel grades. Directly after completion of the pilot phase, further tests with approximately 18,000 rolled coils were run to statistically validate the new strip-steering control method.

Results showed that the absolute mean of the thickness wedge remained largely unchanged, but the standard deviation of thickness wedge over the strip length could be significantly decreased. This improvement was achieved for all of the mill’s rolled products, independent of their particular material grade. During the performance-test phase, no cobbles were detected that would have been caused by strip-run failures or during threading. This was in stark contrast to the cobble rate of 0.1% that was previously common for the mill.

The newly developed control as well as the respective measuring equipment is now in regular use at thyssenkrupp Steel Europe’s WBW1 Duisburg plant. Based on the success of the project, further installations at other plants and for other steel producers are expected.

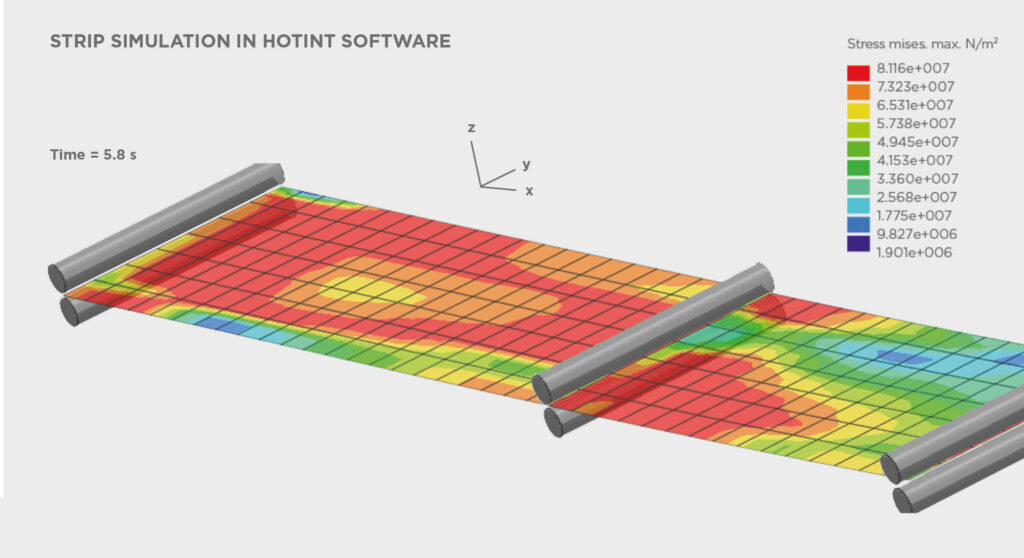

Prior to its implementation at the real plant, the new control strategy was rigorously tested by means of numerous simulation-based studies. For this purpose a new computer-simulation model of the overall strip run was developed. The respective model consists of two coupled sub-models: the “Free Strip Model,” implemented through the framework of the HOTINT software, and the “Roll Gap Model,” implemented in a separate, dynamically linked library. The software tool not only allows for autonomous studies of the overall strip motion to be performed, it also provides an interface to MATLAB/Simulink, through which the controller is implemented.