The extensive R&D efforts of Primetals Technologies are an integral part of the company’s larger strategy to continually promote innovation for the metals industry. In this series, we present new, remarkable solutions pioneered by Primetals Technologies’ engineers — solutions that may still be in their infancy today but have the potential to change the way steel and other metals will be produced in the decades ahead.

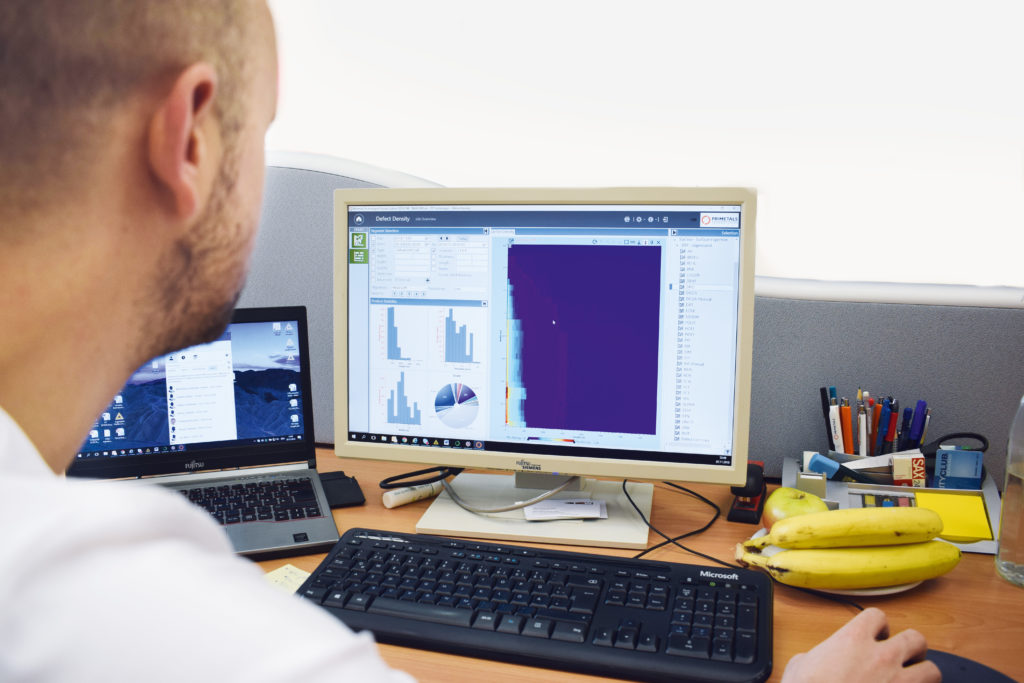

Manfred Kügel, data scientist at Primetals Technologies, has a colorful and diverse job. While his main tool clearly is his computer, his tasks range from data analysis and the evaluation of rule-sets to the creation of entirely new algorithms to solve problems that previously remained unaddressed. He does all this with great ingenuity and persistence—as well as a very high intake of seasonal fruits (see Figures 1 & 3), which give him the energy to come up with fresh ideas.

Customer-oriented development

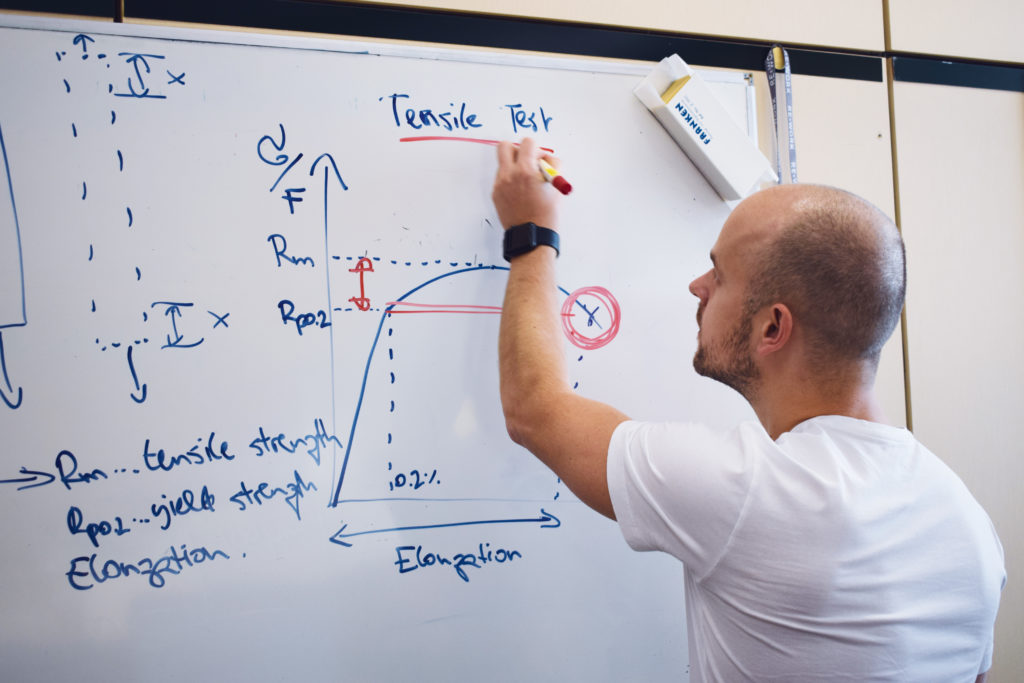

Much of Kügel’s work starts with specific issues that steel producers are dealing with. These issues may be related to quality concerns over the respective manufacturer’s end products or the need to improve certain aspects of the steel-production chain—for instance, the alloying concept. Whatever the problem, Kügel will use production data provided by the customer to make data-driven assessments and draw his conclusions as to what’s going on and what needs to be improved. Of course, his work is highly dependent on the domain experts of Primetals Technologies, who support him with their knowledge and experience of the more intrinsic details of the steel-production process. Since he works in tandem with non-programmers, it is indispensable to occasionally visualize the objectives of new projects in a straightforward manner. Kügel says he has found that using a rather “non-techy,” classic white board is the best way to sketch out mutual challenges and goals. It allows him and his colleagues to brainstorm and ensures that everyone is on the same page regarding the project’s objectives.

Through-Process Optimization

Kügel has the important role of being one of the main designers of Primetals Technologies’ Through-Process Optimization (TPO). This renowned technology consists of the Through-Process Quality Control IT system and an expertly crafted rule-set called “Through-Process Know-How.” With the combined power of these two components, TPO enables steel manufacturers to make the inner workings of their production process more transparent, to increase end-product quality, introduce higher levels of flexibility in terms of batch sizes and raw materials, and realize easier and faster product development. Kügel crafts and improves the algorithms used in TPO and ensures that the solution remains at the cutting edge of technology.