The extensive R&D efforts of Primetals Technologies are an integral part of the company’s larger strategy to continually promote innovation for the metals industry. In this series, we present new, remarkable solutions pioneered by Primetals Technologies’ engineers—solutions that may still be in their infancy today but have the potential to change the way steel and other metals will be produced in the decades ahead.

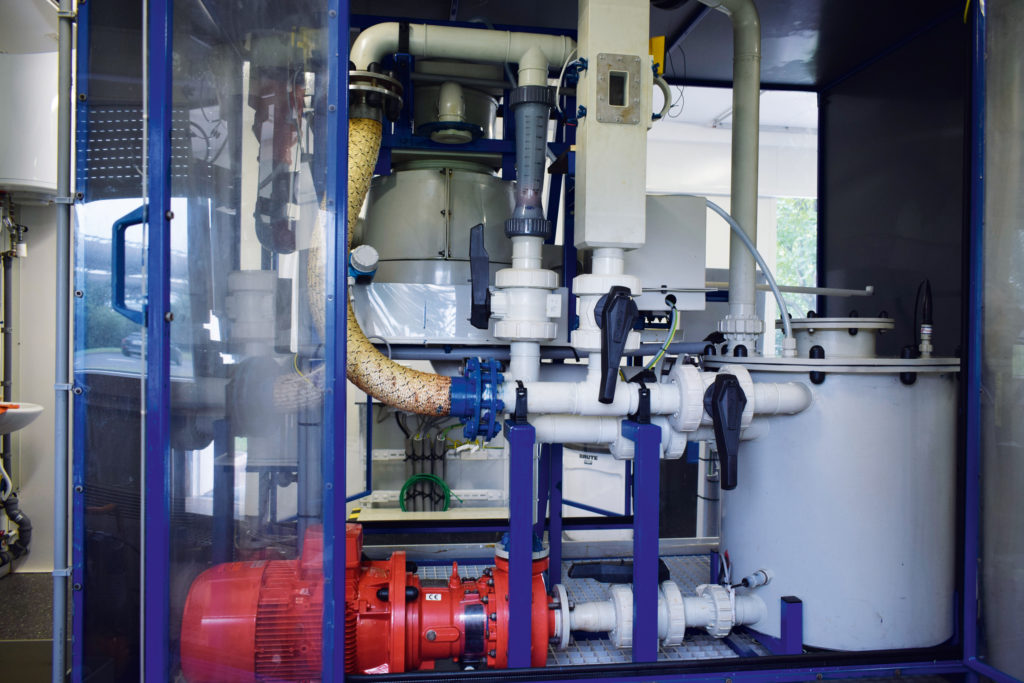

The moment you meet him, you can tell that Sabari Sridhar is a tireless and dedicated researcher. His eyes light up and his energy feels almost electric as he steps into what he calls his “pickling simulator.” The story of how the simulator, a tiny yet effective and highly specialized laboratory, came into being, is a long and colorful one. Because it was built on the location of Primetals Technologies Austria in Linz, a large number of permits had to obtained from the local government. First the construction of the container itself had to be greenlit; then Sabari was asked to demonstrate that all relevant health and safety standards would be met. Dedicated measures had to be taken to address additional environmental concerns: Sabari would be experimenting with acid, and any evaporation had to be proactively prevented. Finally, after 18 months of jumping through regulatory hoops, Sabari was able to conduct his first experiments.

PICKLING, THE BETTER WAY

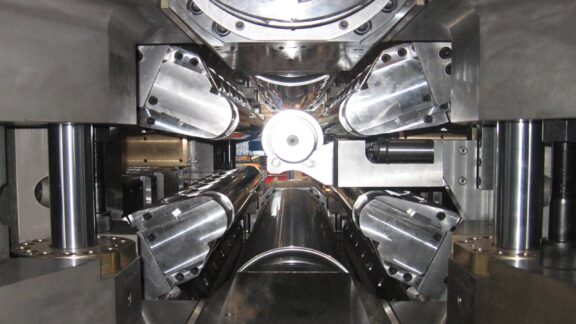

Sabari’s dedication to the project quickly paid off. The simulator showed that a new pickling technology Sabari and the team had developed actually worked when tested in the real world. “Advanced high-strength steels are difficult to process when it comes to pickling,” Sabari says. “After hot rolling, a layer of iron, silicon, or manganese oxides builds up on the surface of the strip. This is very hard to remove with conventional methods.” Sabari made it his mission to pioneer a new approach to pickling.

DEMANDING STEEL GRADES

Exactly how the innovation by Sabari and his team functions is still top secret. But the technology has already attracted the interest of one of the world’s largest steel producers, who is now partnering with Primetals Technologies to advance the development. “I’m really happy with this partnership,” says Sabari. “Our partner provided us with samples of novel, next-generation steel grades, which were next to impossible to obtain otherwise.” These samples are subjected to the special surface treatment in the pickling simulator, using the same acid as in conventional pickling but to much greater effect. “Advanced high-strength steels are known to be tricky, but they are also in very high demand by the automotive industry,” Sabari explains. “They are used for high-end steel applications such as car bodies—very cutting-edge and future-oriented.” So do you need a special future-proof permit to make or own them? “Probably many,” Sabari says. l