This post is also available in: 简体中文 (Chinese (Simplified))

At Primetals Technologies, it is our mission to pioneer innovative solutions that will change the way steel is produced. We listen closely to the needs of our customers in the metals industry to help them stay ahead of the curve. We develop technologies that point the way to the fully automated plant of the future—a plant that is far more energy efficient, more flexible in terms of lot sizes and raw-materials, and capable of orchestrating all production-related activities using advanced digital tools.

Pioneering unique solutions

As pioneers at heart, we are driven to push the limits of what’s possible for metals producers worldwide. Our determination to create new, powerful solutions has led to numerous innovations that are still unique in the industry. While we could not list all of them here, we’ll mention some of those that have been attracting particular interest. Learn more about the technologies discussed below by visiting our website primetals.com.

SOLUTIONS ONLY AVAILABLE FROM PRIMETALS TECHNOLOGIES

Ironmaking

In the field of ironmaking, we make a point of innovating for nature. Our MEROS dry-type multi-component gas-cleaning solution is the best technology on the market for environmentally compatible sintering. Sinter Waste-Gas Recovery reduces the overall sinter waste-gas flow and increases energy efficiency. New, more reliable, and more durable stave solutions for blast furnaces are another unique contribution to more effective and eco-friendly ironmaking.

Steelmaking

In the steelmaking area, we could not be more proud of our LiquiRob—a highly versatile robot that takes care of the jobs too dangerous for human operators. Lomas uses sensor technology to continually monitor the off-gas stemming from the steelmaking process; this information is then passed on to the Dynacon system for dynamic blow-end detection. The EAF Quantum is unique by virtue of its capability to pre-heat scrap for increased energy efficiency.

Casting & Endless Strip Production

Primetals Technologies is world-renowned for its caster technology, with innovations such as the process models DynaPhase, Dynacs 3D, and DynaGap. The legacy is continued with the Single-Roll DynaGap Segment, DynaJet Flex secondary-cooling system, and Mold Expert mold-monitoring and sticker-prevention solution. Arvedi Endless Strip Production combines endless thin-slab casting and rolling, and can produce hot-rolled strip as thin as 0.6 millimeters.

Hot and Cold Rolling

When it comes to hot and cold rolling, Primetals Technologies has many innovative solutions in its portfolio that can’t be found anywhere else—such as the Hyper Universal Crown Control Mill. The Wedge and Camber Control technology is unique in its sophistication. Power Cooling is synonymous with unparalleled cooling performance, particularly for high-end steel grades. And the iBox is the descaling solution of choice that requires no circulation heating or jet nozzles.

Digitalization

Primetals Technologies has developed the concept of the Metals Orchestra to illustrate its vision for the digitalization of steel production. The core idea is that a steel plant is much like an orchestra, with individual, highly versatile “players” (aggregates) and a digital “conductor.” This conductor is represented by a unity of sophisticated digital solutions that cover everything from production management and quality optimization to maintenance scheduling.

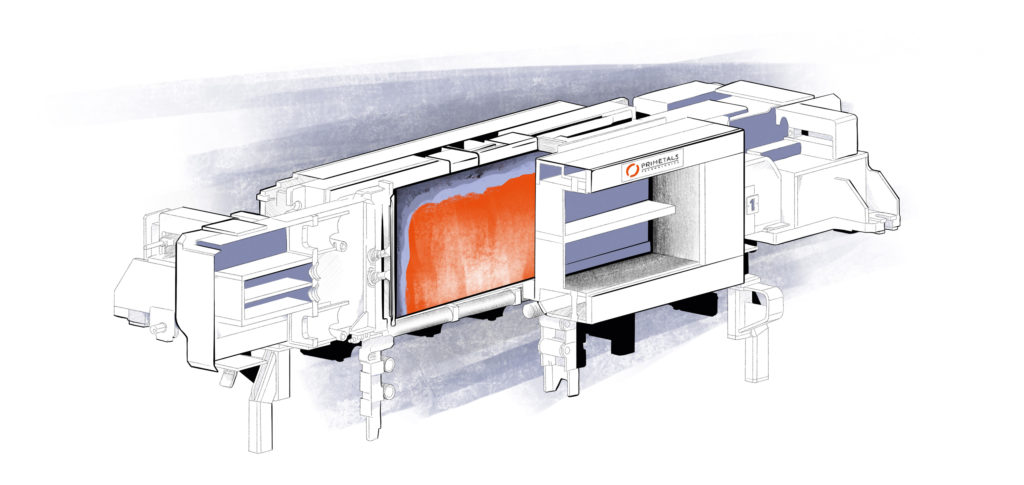

Have you ever wondered what the inside of the caster mold looks like? There are plenty of good reasons why you might be curious: the inner workings of the caster determine to a large extent the quality of the cast slabs, blooms, or billets. It is also essential that the caster operates smoothly and any stickers are detected early, as stickers can lead to breakouts and to costly standstill times. Mold Expert was designed to let you do exactly that—to see what goes on inside the mold. With 250 installations to date, Mold Expert is the best-selling mold-monitoring solution worldwide. The newest version, Mold Expert Fiber, adds a new level of detail to the system by increasing the number of measuring points from 120 to over 3,000.

Nicole Oberschmidleitner, together with her team, has made huge steps forward with Mold Expert. It was under her guidance that Mold Expert Fiber was developed, which uses fiber Bragg gratings to increase mold-specific data by a factor of 10–20. This gain in information led to a significant refinement of the algorithms used to monitor and analyze the casting process—and allowed Oberschmidleitner to keep an even more attentive “digital eye” on aspects such as mold levels and subminiscus speed inside the mold. Oberschmidleitner also pioneered new support packages for Mold Expert customers: “I realized we had more to offer steel producers in terms of providing them with specialist support after implementation. Over the years, we have forged many lasting relationships, ensuring that our customers can realize Mold Expert’s full potential.”

… is the most recent version of Mold Expert and uses fiber Bragg gratings to monitor the condition in the caster mold.

Nicole Oberschmidleitner…

… is Head of Mechatronic Products at Primetals Technologies and is committed to addressing steel producers’ challenges with innovative solutions and services.

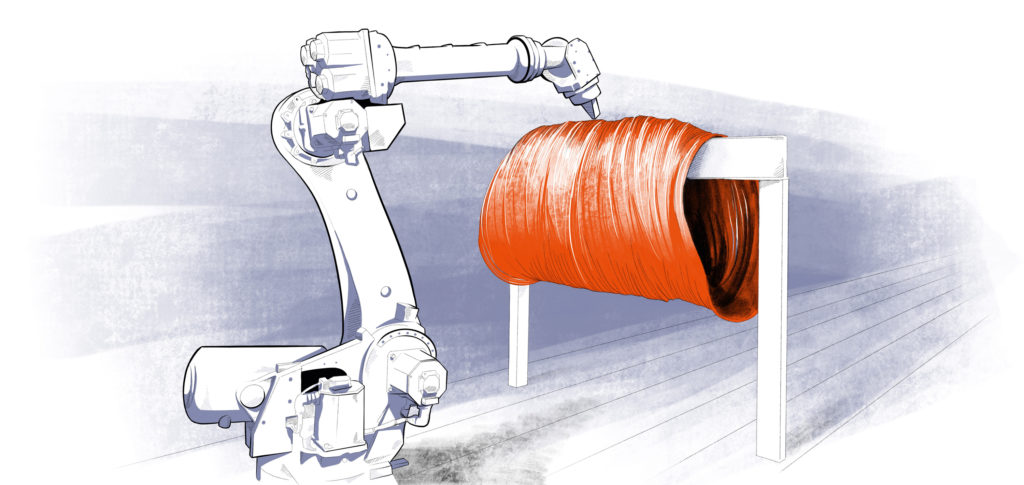

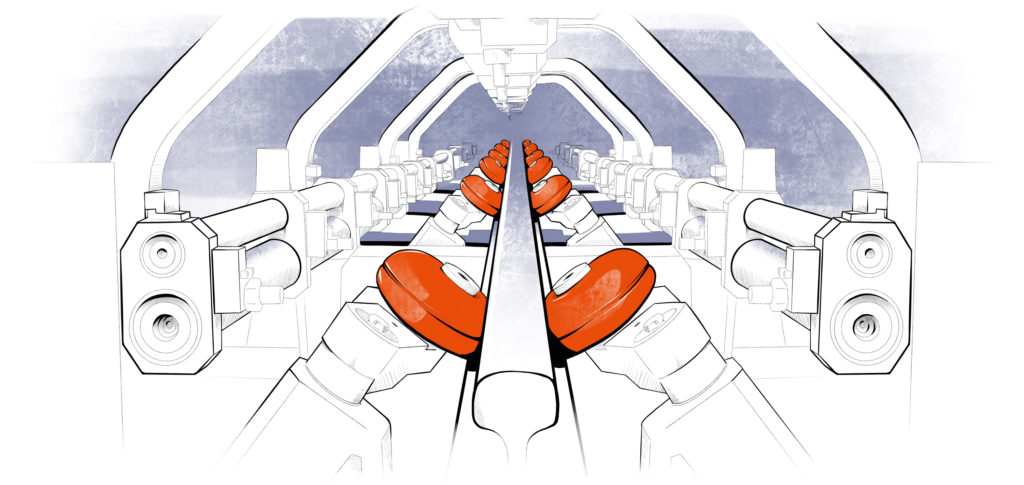

The cooling process in long rolling naturally produces wire rod coils with head and tail-end metallurgical inconsistencies. Trimming those ends has proven to be a production challenge, however, and Head of Technology Matt Palfreman and his R&D team in Worcester, Massachusetts, U.S.A., wanted to find a better approach. High-speed shear accuracy was difficult to maintain at speeds of 120 meters per second. Manually counting rings to clip off and remove was tedious and dangerous. So the team considered adapting existing technology with a novel application—vision-enabled robots programmed to trim coils exactly where needed.

“We wanted a completely different alternative to competitor products,” says Palfreman. “Robotics seemed the right solution.” The team soon discovered it “started with the most difficult of possible applications,” he says, “but we went all in.” Testing numerous iterations of rapid prototypes created with 3D printers involved “a massive effort and long hours” before the team was ready to share its results with the first customer. The new robot has proven to be simpler, safer, easier, and faster than existing approaches. Workers previously tasked with a repetitive, potentially hazardous operation can now be retrained with new skills in robot system maintenance. Steel producers benefit from the greater consistency of coil and higher overall metallic yield. And soon the vision-assisted capabilities of robots will improve other stages of the long rolling process

… for long-rolling applications can be programmed to trim coils exactly where needed.

Matt Palfreman…

… has pioneered vision-enabled robotics by prototyping new designs using 3D printing technology.

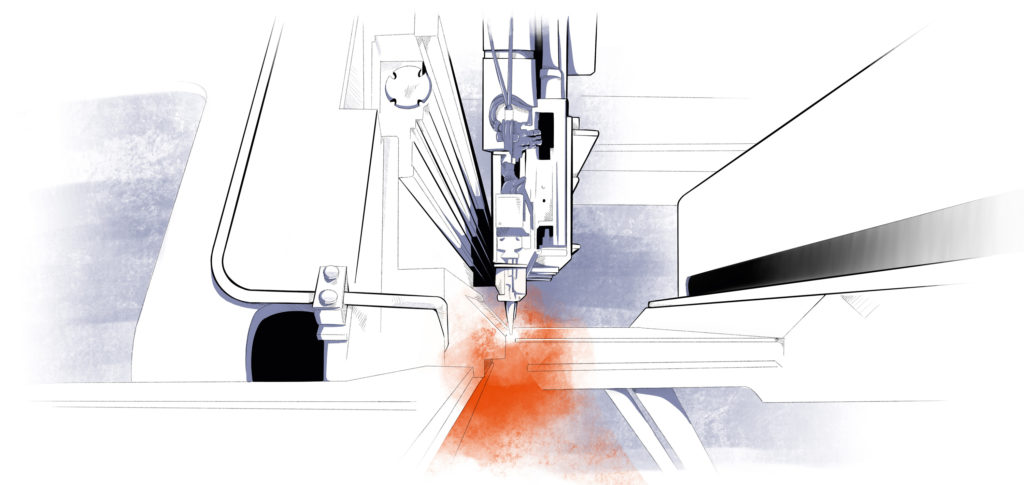

The laser-welder solutions of Primetals Technologies are unique within the steel industry. They are highly effective and reliable, and can be used to both cut and weld a large variety of steel grades: dual-phase, transformation-induced plasticity, twinning-induced plasticity, boron, silicon, stainless, and specialty steels can all be processed by laser-welder-based production lines, reaching tensile strengths of up to 2,000 MPa. The laser welders from Primetals Technologies are designed to prevent any deformation of the strip during treatment. Compared to other welders, they deliver much higher performance, with a 20 to 50% boost for welding and a 20 to 100% increase for cutting, depending on strip thicknesses.

Primetals Technologies has over 20 years of experience with laser-welder solutions, and Thomas Vallee has pioneered many of the most recent advancements. Vallee worked on adapting the laser-welder technology, which had originally been crafted for medium-size applications, to heavy ones. “To make a good weld, you need a perfect cut,” he says. “Steel producers want a solution that reliably achieves both, without any deformation of the strip.” Vallee likes to push the limits of what’s technologically possible: “I enjoy developing solutions that surpass others performance-wise. But they also have to be dependable and easy to operate.” To underline this conviction, Vallee refers to a Thomas Edison quote: “The value of an idea lies in the using of it.

… from Primetals Technologies are reliable and easy to maintain, and require up to 50% less energy than other laser welders.

Thomas Vallee…

… is the Lead Product Manager for Primetals Technologies’ laser welders, which he wants to be both innovative and practical.

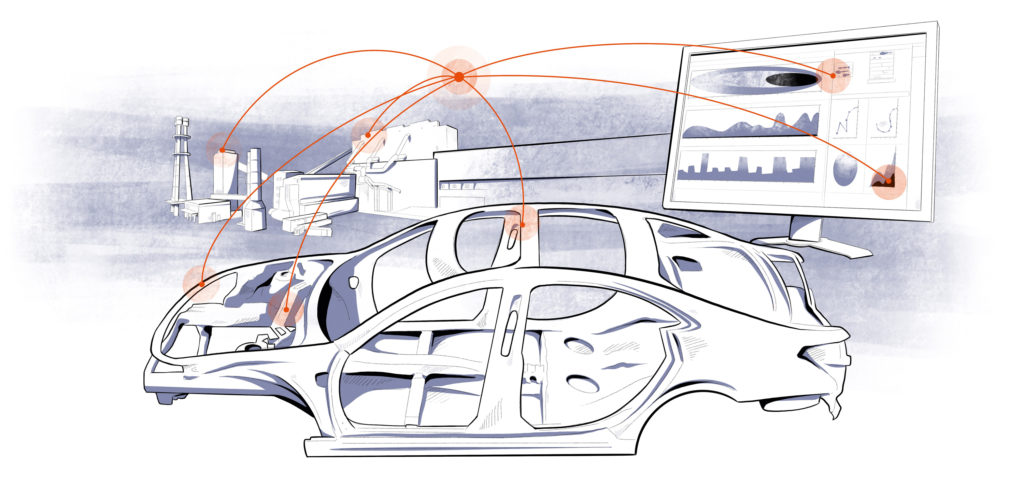

An innovative solution only available from Primetals Technologies, Through-Process Optimization (TPO) helps steel producers make the most of their equipment. It indicates in great detail what parts of the production chain could be further improved to facilitate a transition to higher-quality steel grades—for instance, steels for the automotive industry. TPO relies on two things: a powerful software system that incorporates many thousands of data points stretching right across the production chain, and the experience and insights into the steel-production process that the specialists at Primetals Technologies have gained over decades.

“Creating TPO was hard because it was based on such a novel approach,” says Dr. Thomas Pfatschbacher of the early days of his brainchild. “We were a small but dedicated team, and I remember constantly facing completely new challenges, coming up with new ideas for how to resolve them in my car, on business trips, and late at night.” At the core, the goal of TPO was to pioneer a new solution for the digitalization of all production-related processes in a steel plant. The combination of expert advice and information technology was unique, as other companies only provided traditional consulting without the ability to enable knowledge-based quality control. TPO emerged as a driver for customer-oriented innovation at Primetals Technologies: “The better we understand a steel producer’s situation, the more effectively we can support them,” says Pfatschbacher.

… uses human expertise and artificial intelligence to support steel producers in holistically optimizing their products, their processes, and their operations.

DR. THOMAS PFATSCHBACHER …

… wanted to channel decades of operational experience into one intelligent IT system, which could assist steel producers in upgrading their product portfolio.

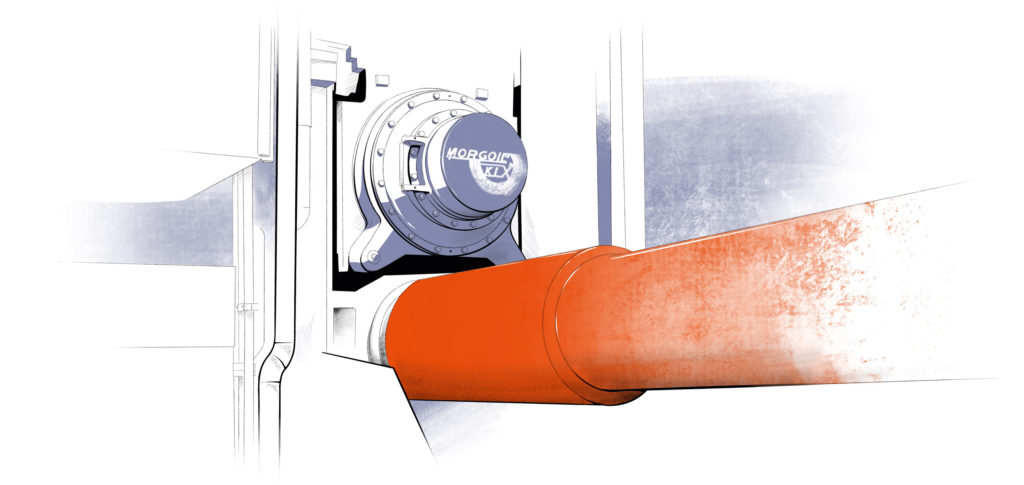

In 1932, the Morgan oil-film bearing, branded MORG-OIL, offered rolling mills a radical alternative design—a thin film of oil with immense load capacity. The new MORGOIL bearings reduced friction, increased speeds, and lowered power demands, all while achieving better product tolerances with increased reliability. To date, the tapered-neck MORGOIL bearing has seen three generations of hydrodynamic technology. The latest innovation, the MORGOIL KLX, has maintained the position as the industry standard, while offering more than 25% increased capacity in the same space.

Thomas Wojtkowski, a former aerospace engineer, led the team behind the MORGOIL KLX. “The challenge was to redesign the bearing technology without overloading other components that mate with the bearing,” he says. For the first time ever, the new technology was tested on a custom-built half-scale device that runs at realistic speeds and loads. “We measured what was actually happening inside, rather than relying on theoretical work,” he says. That knowledge allowed the MORGOIL R&D team to refine the design with a thinner bearing still robust enough for real-world applications. “The proportions looked so different that many people were skeptical,” says Wojtkowski. But 100-plus mills later, the technology has more than proven its value. “It’s great to see how widely KLX has been adapted to so many types of mills worldwide. Our team is very proud of the success of the product.”

… is the latest MORGOIL product, offering 25% higher capacity at the same space requirements.

THOMAS WOJTKOWSKI …

… took an innovative approach to advancing the MORGOIL bearing and created a half-scale testing device that allowed his team to gain invaluable real-world insights.

idRHa+ is the inline injector dual-phase rail-hardening system from Primetals Technologies, capable of applying the desired temperature profile and microstructure distribution of the rails during manufacturing in real time. Optimized for the requirements of today’s rail producers, idRHa+ is fully Industry 4.0 compatible and offers advanced thermo-metallurgical process control, state-of-the-art production management, and strictest quality assurance. The system was designed from the ground up to be future proof and provides pioneering, highly advanced functionality. It can predict the rails’ material properties in terms of hardness gradient, microstructure transformation, deformation behavior, and more. The high energy efficiency of idRHa+ rounds off a solution that is without equal in the metals industry.

Alberto Lainati was involved with the development of idRHa+ from the beginning. He started by studying in detail what market conditions the new technology would be facing and got in contact with rail producers, end users, and standardization organizations around the world. “With rails, you have zero room for mistakes,” says Lainati. “Rails are among the very few steel products that go into operation as rolled, so their performance, consistency, and reliability are absolute.” For idRHa+, an innovative pass-through rail-production method had to be crafted, with selective and flexible quenching protocols using water, air, and mist. “Ahead of the first production run, I was up all night, hoping it would go as planned.” It did.

… integrates with advanced sensors and electronics, thus implementing Industry 4.0 principles to harden rails.

ALBERTO LAINATI …

… has been with Primetals Technologies (and predecessor companies) since 1989 and led the efforts behind idRHa+.

What’s next in the world of metals

What are the “hot topics” for steel producers who want to anticipate the future and ensure their long-term success? The experts of Primetals Technologies have studied the current trends, and have carried out extensive research to prepare for future developments. Based on their findings, they are pioneering innovations designed to meet the challenges ahead. But even with the technologies in place to meet these demands, every steel producer still has to find the ideal implementation strategy. Primetals Technologies is ready to support its customers individually.

- Utilize new digital solutions

- Maximize productivity

- Increase operational flexibility

- Enhance product quality

- Lower operational costs

- Improve asset utilization

- Lower maintenance costs

- Increase safety of staff

- Minimize energy consumption

- Lower emissions