This post is also available in: 简体中文 (Chinese (Simplified))

Standardized sample taking is key to running sinter plants at full potential. The fully automated sinter raw-mix analyzer takes productivity to a new level.

Continuous optimization and constant supervision of the sintering process are key to meeting productivity goals and other business objectives in today’s competitive environment in ironmaking. When it comes to the precise control of the properties of the sinter raw mix in particular, there is still much room for improvement in today’s plants. Identifying and reacting to changes and fluctuations in these parameters as quickly as possible can yield enormous benefits in terms of sinter-plant productivity.

As things stand, however, the decisive factor in monitoring and controlling raw-mix properties is often the experience and expertise of a handful of operators working at the facility. In many cases, parameter control barely goes beyond visual and sometimes manual inspection by the operator in charge. Personnel and even shift changes can be detrimental or even disruptive to the process. The process of manual sampling and subsequent lab testing is too slow to be able to react to parameter changes. And proven online measurement solutions are scarcely available at this point.

The goal: automation & digitalization

This is what motivated Primetals Technologies and its partners at voestalpine Stahl Donawitz, an Austrian steel producer, and at Eirich, a German supplier of machines, plants and services for mixing and granulation technology, to launch an R&D project for a completely new breed of sinter raw-mix analyzer. The ambitious goal was to comprehensively automate and digitalize the sampling process and feed the obtained data into Level 2 automation, combining them with process models and Expert Systems to reap the full benefits in terms of productivity and efficiency.

Sintering and permeability

Essentially, sintering of fine iron ores is achieved by causing a combustion zone to move progressively through a suitably prepared porous bed of iron ore, different additives such as limestone and dolomite, and solid fuel (e.g., coke breeze). The granulated particles are agglomerated by fusion and the formation of a partial slag bond. Generally speaking, the faster the combustion zone passes through the bed, the higher the sintering rate will be—and therefore also the productivity of the sintering strand. As regards the relevant process parameters, it has been shown that permeability, i.e. the rate at which air can be drawn through the bed, is the key value in the properties of the sinter raw mix: High permeability allows for higher suction rates and thus higher sinter-strand productivity. The property can easily be adjusted by fine-tuning the amount of water that is added to the mix as a binding agent. But hitting and maintaining the “sweet spot” of the raw mix can only be achieved by frequent, high-quality online permeability and moisture measurements, ultimately combined with process models and Expert Systems.

A new control concept

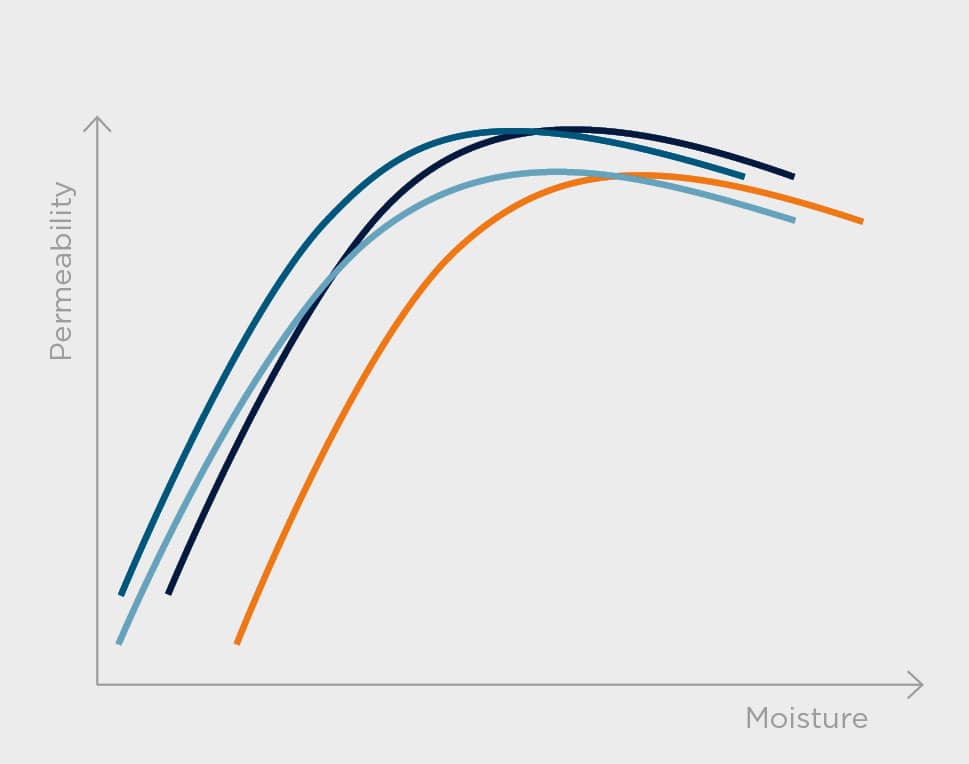

One of the first tasks in the R&D project was to run an extensive series of tests to establish the exact correlation between moisture and permeability on the one hand, and the effect of permeability on sinter strand productivity on the other. The results formed the basis of an advanced moisture/permeability control concept that is implemented with real-time robotic measurements.

Engaging the robot

The point of discharge of the conveyor to the feeding hopper of the sinter machine was picked as the location best suited for installing the robotic sampling and measurement equipment, as it is easily accessible for cleaning and maintenance and allows excess material to be fed right back into the process. There is no need for any additional conveyors or transport systems.

To take a representative sample, the robot first picks up a vessel from a tool-changing system and holds it into the material stream for filling. Then the material is fed into a rotary divider to fill several cups with screen bottoms. These cups are transfered to measuring stations (Figures 2 and 3) where the raw mix is first weighed to calculate bulk density and then tested for gas permeability and moisture: Air is drawn through the cups to obtain the necessary values of pressure drop and volume-flow rate for permeability. Additional measuring stations can be easily added and an operator can request additional sample cups for outside laboratory testing to be put onto the turntable of a security gate (Figure 4). Once the measurements are all performed, the robot cleans up after itself: it empties the cups into the sintering belt’s hopper and removes any remaining material with a rotating brush and stationary air nozzles.

Putting the data to use

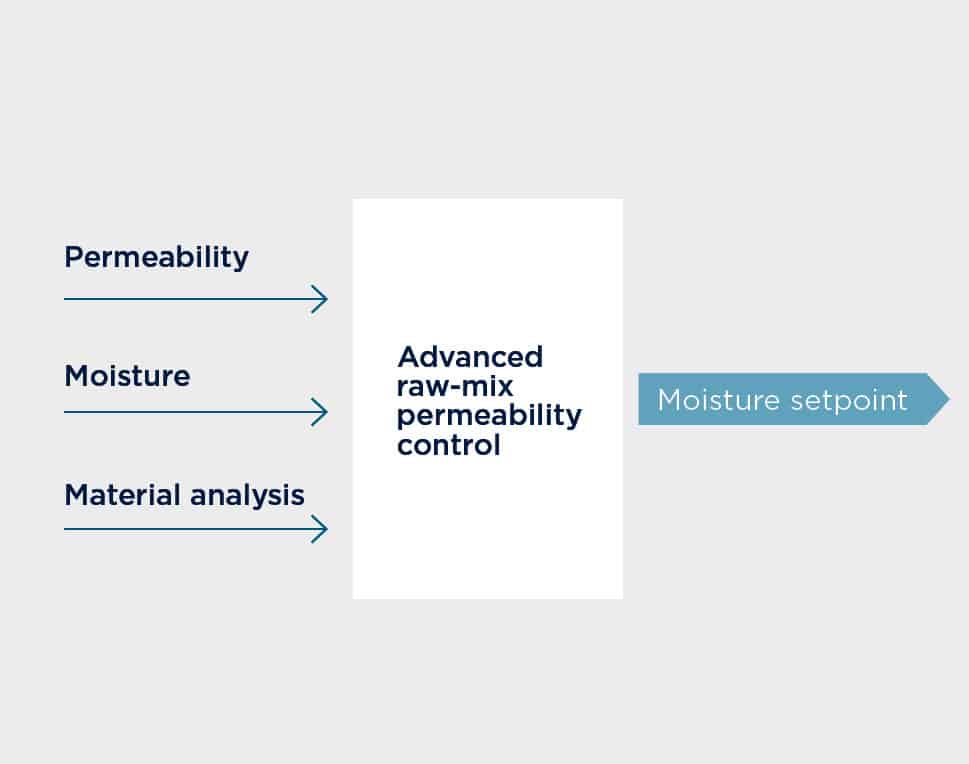

The moisture setpoint undergoes controlled variation as the robot continually runs tests to determine the effect on moisture/permeability. From this information, the control deduces the current position on the moisture/permeability curve (Figure 5) and reacts accordingly—by adding more or less water to the mix. In doing so, the Expert System also takes into account data on current moisture, the chemical composition of the raw mix, as well as other sinter-plant parameters.

This has allowed operators at voestalpine Stahl Dona-witz to run raw-mix moisture levels that they previously would not have dared—and increase productivity as a result.

Interview with

Johann Reidetschläger

Dr. Johann Reidetschläger is a process technologist at Primetals Technologies, specializing in agglomeration processes.

Johann Reidetschläger: When visiting sintering plants and asking customers about their pain points, there always seemed to be a demand for automatic sampling and online analysis of the sinter raw mix in connection with optimization and continuous supervision of the process. This encouraged us to go ahead and develop a system to meet this demand—the idea for which we had been kicking around for quite a while.

What were the biggest challenges for you and your partners in the project?

Reidetschläger: Generally speaking, it was the implementation of the new robot system in a harsh industrial environment, and interconnecting it to the existing equipment and control system. An essential task was to streamline the collaboration between several companies and our own people—from such different fields as process technology, layout, automation, robotics, and mechatronics, as well as data modelling.

Which kinds of plant would benefit the most from fully automatic raw-mix analysis?

Reidetschläger: I think pretty much any plant could benefit greatly—I don’t see any exceptions. Automatic and standardized sampling and analyzing is an unfullfilled wish in many plants I know. Now this can be rather easily achieved in sintering plants of any scale.