This post is also available in: 简体中文 (Chinese (Simplified))

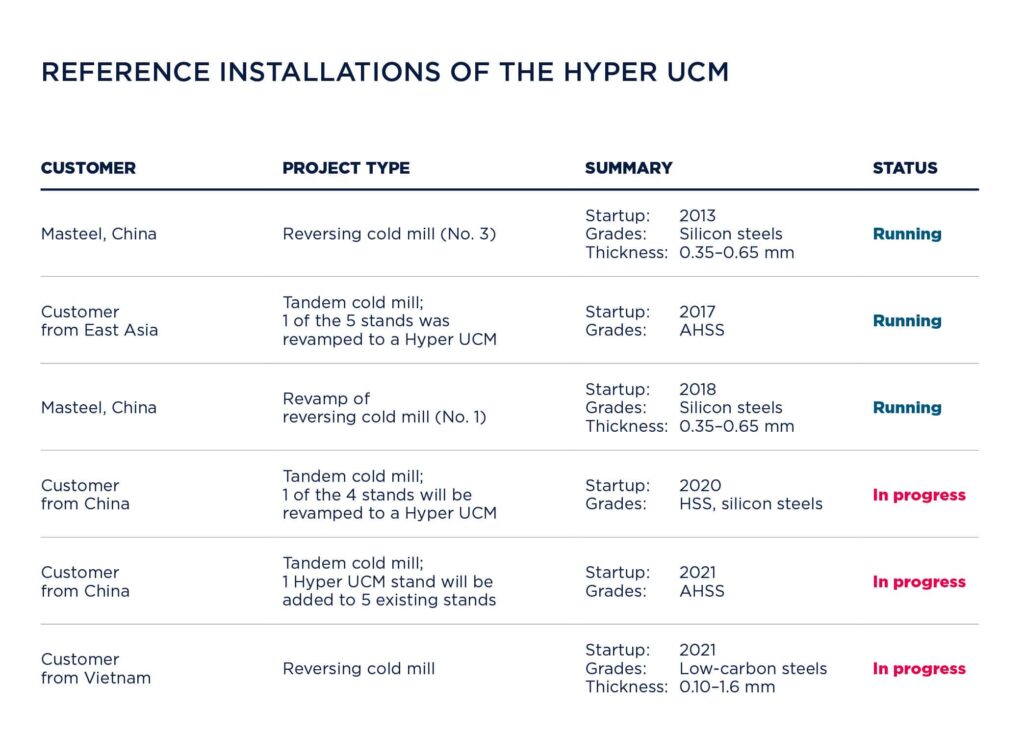

The Hyper UCM is the result of pioneering innovation combined with decades of refinement. It represents the technology of choice for new cold rolling mills but can also be implemented in the context of reversing cold mill and tandem cold mill upgrades. This article examines the development and refinement of the Hyper UCM, and showcases a recent reference installation at Chinese steel producer Maanshan Iron & Steel Co. (Masteel).

Given its significance in the industry, it is no exaggeration to say that the 6-Hi mill design marked a major milestone in the history of rolling technologies. This invention changed the course and shape of rolling mills as we know them today, and renowned Japanese technologist Dr. Toshiyuki Kajiwara (see “Taking New Inspiration from Mill Operators”) was instrumental in its development. Inspired by his passion to create the most user-friendly, high-performance rolling mill possible, Primetals Technologies later evolved his design to create a highly sophisticated cold-rolling solution.

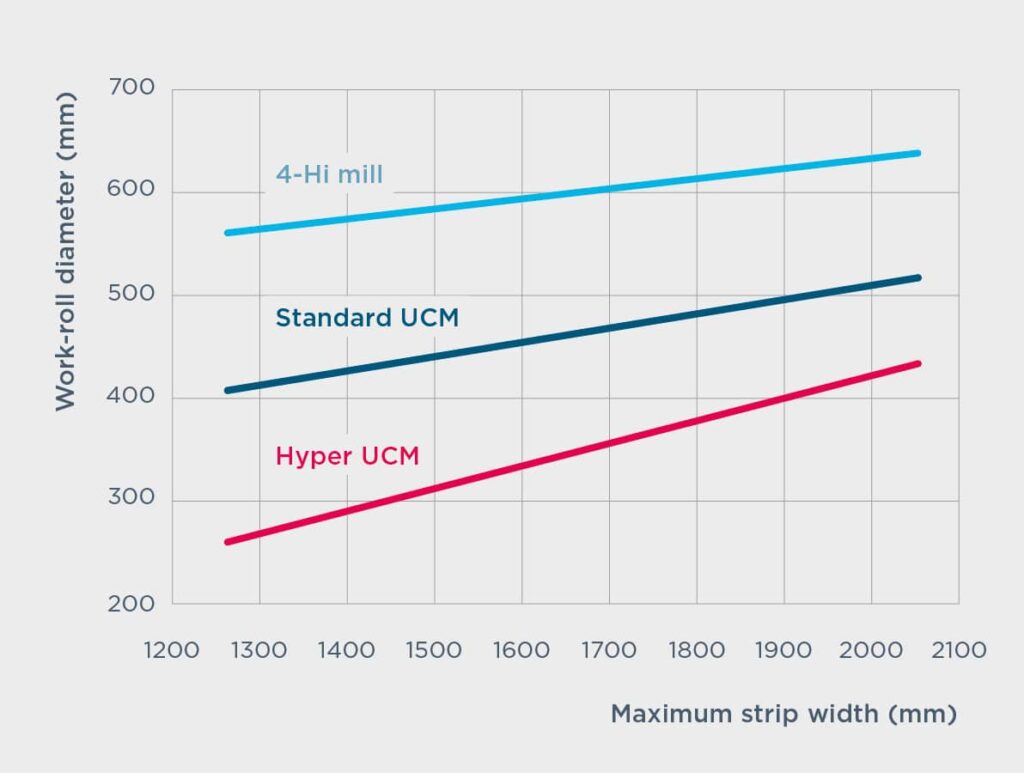

The Hyper UCM is the most advanced iteration of the Universal Crown Control Mill (UCM) and takes after Dr. Kajiwara’s 6-Hi mill innovation. While retaining all the incredible advantages of the standard 6-Hi UCM, the Hyper UCM features work rolls that are 20 to 30 percent smaller than those used in the standard UCM. It can roll materials of much higher strength into thinner strip, achieving uncompromising levels of quality and productivity.

The installation of a Hyper UCM enables steel producers to expand their product portfolio and gain a competitive edge in the metals industry. For producers to stay relevant in a low-carbon world, the manufacture of extremely strong yet thinner and lighter strip is no longer merely an option, but a must. The implementation of production methods that consistently deliver sophisticated steels has become a key strategic goal, because the demand for electric and lightweight vehicles is continually rising. The Hyper UCM is ready to meet this challenge.

Genesis of the 6-Hi Mill

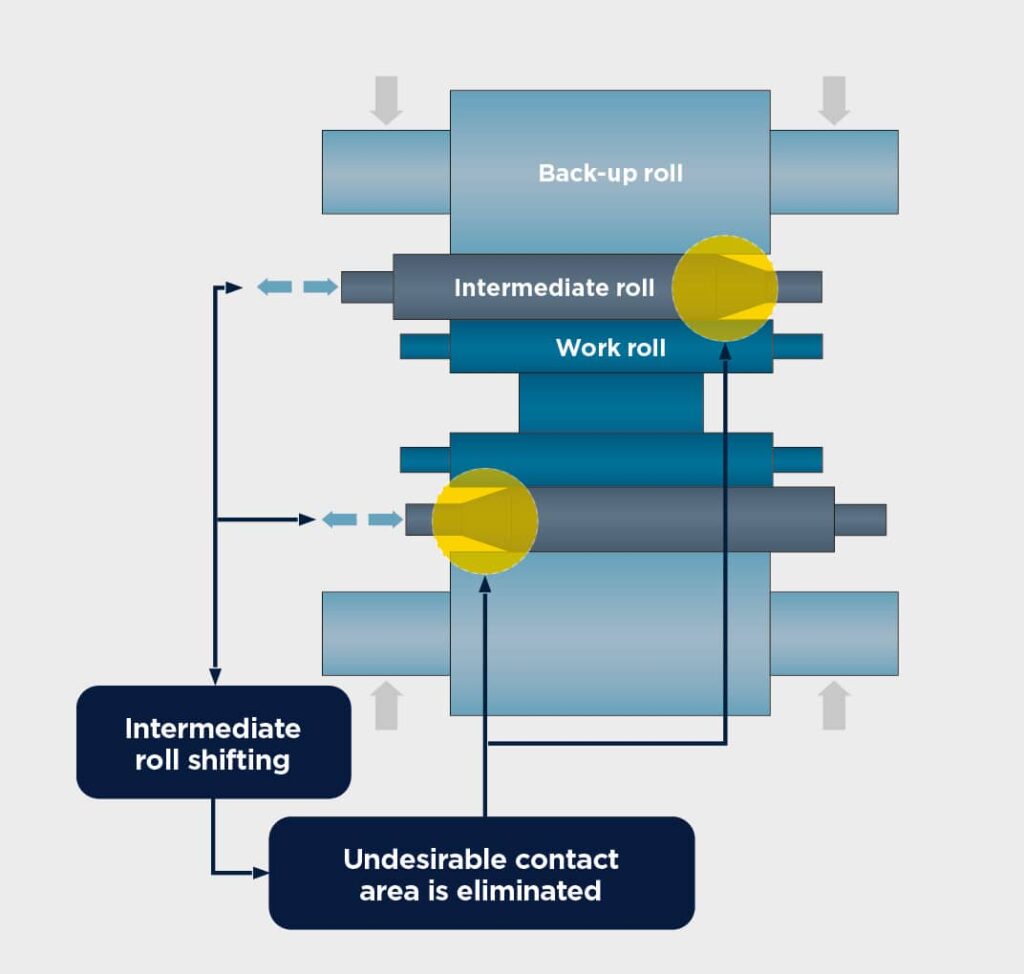

Before Dr. Kajiwara‘s innovation, which represents a quantum leap in terms of rolling methods, the 4-Hi mill consisted of a set of backup rolls and a set of work rolls were available as standard. In the 4-Hi mill, work rolls and backup rolls would come into contact with each other at their outer sections, at the areas that extend outside the strip width. These sections are known as the “undesirable contact area”, since they cause work rolls to deflect and make it difficult to roll strip to the required flatness levels. To eliminate these areas and roll quality strip on the 4-Hi mill, profound knowledge and considerable experience in mill handling was necessary, owing to the large and complex selection of work rolls that needed to be exchanged according to pass schedule and materials.

Dr. Kajiwara’s solution was to create a 6-Hi structure, a new mill design that employs shiftable intermediate rolls in between work rolls and backup rolls in order to eliminate the undesirable contact area. This groundbreaking method could then be used on a day-to-day basis to produce high-quality strip in a simple and straightforward process, much to the benefit of mill operators.

Arguably the greatest technological advancement of Dr. Kajiwara’s 6-Hi mill was its use of work rolls that are smaller than those of the 4-Hi mill: the 6-Hi mill’s smaller work rolls decreased rolling loads and led to a higher reduction ratio. Another key feature of his 6-Hi mill was its high degree of versatility—something that became particularly evident in day-to-day operation. A single set of straight work rolls could be used for any pass schedule, and there was no need for the operator to change rolls when switching from one product to the next. Consequently, a much smaller roll-inventory size became possible.

In the 6-Hi mill—and therefore in the standard UCM and Hyper UCM of Primetals Technologies—the undesirable contact area between the work roll and the backup roll is eliminated by the introduction of an intermediate roll, which is designed to shift across its axis according to strip width. This design suppresses work-roll deflection and maximizes the effect of the roll benders, which help to control the finer strip shape. Thanks to this innovative mill design, a straight work roll can accommodate any pass-schedule change, and much easier mill operation becomes possible.

The UCM is born

After the inception of the 6-Hi mill, market expectations kept changing and demand for thinner and harder strip with improved flatness characteristics increased. Consequently, R&D efforts to further develop the innovation continued and the Universal Crown Control Mill (UCM) was created. The UCM featured excellent strip-shape control capability, and a stable strip shape could be maintained under varying rolling loads with much less effort. Product yield was also improved as a result of the reduction in edge drop with the UCM. In the 1980s, it was recognized as a next-generation 6-Hi mill that, thanks to its performance, enabled steel producers to expand their portfolio to encompass sought-after high-quality materials.

The UCM has made a massive contribution to a steel industry that was hungry for better and more effective steel production, and has established itself as a reliable solution for rolling high-quality materials. Meanwhile, the growing demand for even harder and thinner materials in recent years has spurred further technological advancement. This is why Primetals Technologies has chosen to create a new mill design that can take the unique advantages of the UCM to the next level.

The discovery of the undesirable contact area in the 4-Hi mill and the respective solution—intermediate-roll shifting—enabled a reduction of work-roll diameter. The schematic to the left indicates the average work-roll diameter derived from plant-specific data of rolling mills worldwide, according to type of mill and strip width. In overall comparison, the work-roll diameter of the standard UCM is approximately 25 percent smaller than that of the 4-Hi mill. The Hyper UCM’s work-roll diameter is further reduced by 20 to 30 percent from that of the standard UCM.

Introducing the Hyper UCM

The Hyper UCM represents this next step in cold-rolling technology. It uses even smaller work rolls, which are driven by a small work-roll drive system. During the Hyper UCM’s development phase, the best combination of roll diameters for achieving the maximum reduction ratio was studied. Primetals Technologies used a simulation technique to calculate the maximum limit for rolling load required to maintain good strip shape, and maximum allowable loads based on roll strength. The simulation showed us what the suitable work-roll diameter would be in order to achieve the highest possible reduction ratio, according to maximum width of the mill. This research laid the groundwork for what would lead to a 20 to 30 percent reduction in work-roll diameter from the UCM to the Hyper UCM.

The technological superiority of the Hyper UCM results in major benefits to steel producers. The Hyper UCM reduces rolling force and the number of passes, and inherits the standard UCM’s excellent strip shape controllability. It also boosts rolling efficiency and effectiveness, and enables the production of high quality materials with cutting-edge characteristics.

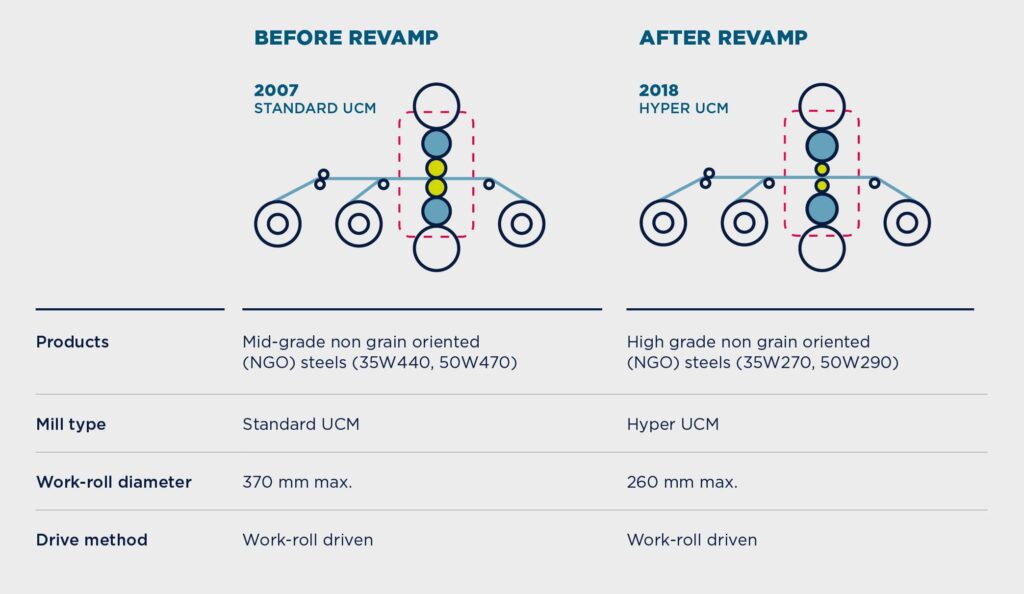

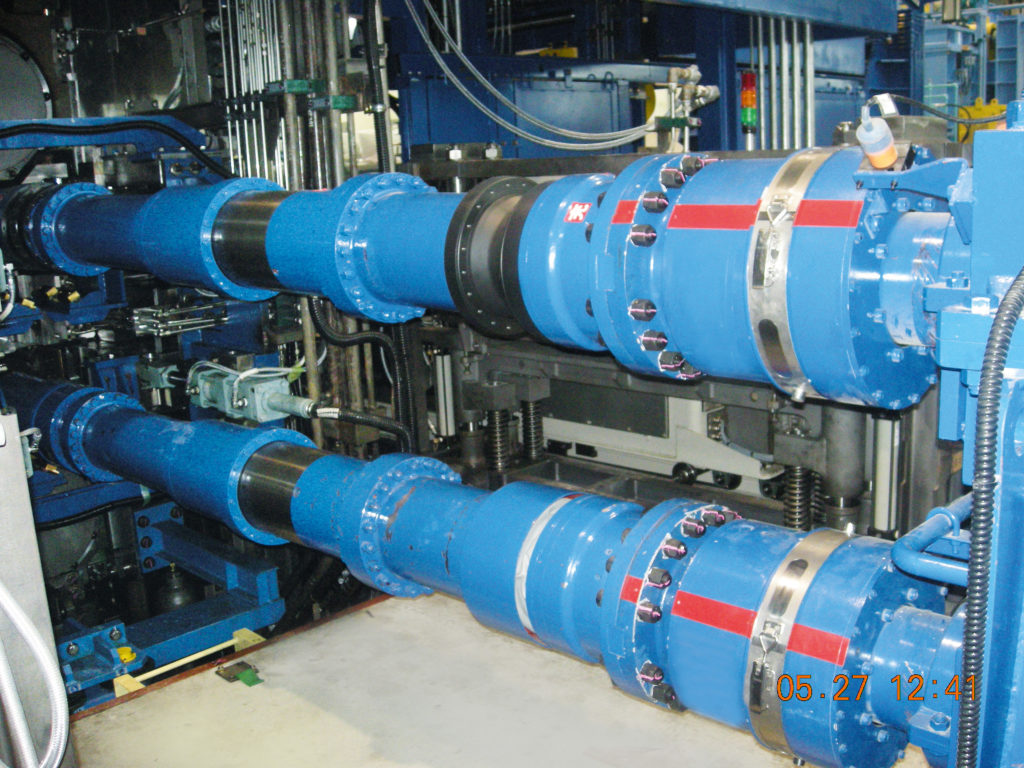

Primetals Technologies recently completed an upgrade of the Universal Crown Control Mill (UCM) for Maanshan Iron & Steel Co. (Masteel), a leading supplier of high-quality electrical steel. Masteel had been producing mid-grade non grain oriented (NGO) sheet since 2007, on their two standard UCMs in a single-stand reversing cold mill (RCM). Their third RCM was commissioned in 2010, using Primetals Technologies’ more advanced Hyper UCM solution, which allows for the production of higher-grade electrical steels. In 2017, Masteel placed an order with Primetals Technologies, this time to upgrade one of their standard UCMs to the Hyper UCM. The project resulted in a substantial boost of the plant’s output and performance. In order to minimize the shutdown period, Primetals Technologies decided to re-use the original housing of the standard UCM, which was possible because its roll-stack dimensions were almost identical to those of the Hyper UCM. The only required modification on the housing was the application of new screw holes for new bending blocks.

The Hyper UCM introduced different work rolls with a diameter of only 260 mm, compared to 370 mm previously. Despite this reduction in the roll diameter, the Hyper UCM was to be work-roll driven just like the standard UCM. The smaller work rolls made it possible to decrease the rolling force and reduce the number of passes. To accommodate the smaller work-roll diameter and the change in rotating speed, a new pinion stand, a new mill drive motor, and a new type of spindle were also installed. Furthermore, Primetals Technologies renewed the bending block, roll-changing car, as well as the entry and exit cobble guards, which helped to realize the implementation of work rolls with smaller diameters. Thanks to the Hyper UCM technology, the revamped RCM is now able to produce higher grades of electrical steel such as 35W270, while the standard UCM only produces up to around 35W440.

Cutting-edge steel grades

Recently, production of the latest type of non grain oriented (NGO) steels—called “new NGO”—and advanced high-strength steels (AHSS), which are harder and thinner than ever, has been growing at a rapid pace. These steels are used in electrical and light automobiles, which support a low-carbon footprint. It is expected that these materials will become increasingly relevant, pushing steel producers to continually adapt and evolve their production lines. The Hyper UCM enables the production of space-age materials and contributes to the sustainable future of the industry, and to the environment.

Over the course of the development of the Hyper UCM, Primetals Technologies discovered the ideal combination of roll diameters. This brought the researchers one step closer to a new, advanced mill. The next step was the application of these findings. In order to implement the desired work-roll size, the technologists had to craft a downsized work-roll drive system with smaller spindles. Although the work roll diameter became smaller, a higher-strength spindle was needed to transmit the required high torque. Nothing short of a technological breakthrough was necessary: a new type of spindle that would be capable of transmitting higher torque to smaller work rolls had to be designed.

Primetals Technologies successfully pioneered this innovation. The new spindle design laid the foundations for the shift to the Hyper UCM. The spindle’s material and structure were improved, significantly increasing its strength compared to conventional models. This new spindle is called Mitsubishi-Hitachi (MH) Spindle, and has the ability to transmit torque approximately 2.7 times higher than that of the conventional Universal Joint (UJ) type spindle. Since its development, the MH Spindle has already proven its merits in the cold mills of several Primetals Technologies customers.

Ready for the Future of Rolling

The advanced features of the Hyper UCM are applicable to reversing cold mill (RCM) and tandem cold mill (TCM). In the case of TCM modifications, the Hyper UCM can be incorporated into the existing TCM to partially replace the stands, so as to facilitate a large-scale and effective production of the latest and highest-quality steel grades. As illustrated by this article’s Masteel reference story [see page 68], RCM upgrades are also highly desirable.

The Hyper UCM is a mill design that has been proven to be remarkably reliable in providing a steady supply of materials that we need for modern living, both now and in the future. As our societies develop and technological progress is made, mill technology is also being continually refined and new, groundbreaking innovations are emerging. The cold-rolling experts of Primetals Technologies will continue to move the world of metals production forward and provide steel producers with the best-possible solutions to meet their strategic needs, wherever they may be located.

Interview with

Shinichi Yasunari

Shinichi Yasunari is one of Primetals Technologies’ most seasoned rolling experts. He was instrumental in developing the Hyper UCM.

What was your biggest challenge in the development of the Hyper UCM?

Shinichi Yasunari: We conducted hundreds of simulations to find the ideal combination of work-roll and intermediate-roll diameters. Our goal was to realize the highest-possible reduction ratio without compromising strip shape or exceeding contact-stress limits between rolls. In the end, we successfully applied work rolls that are 20 to 30 percent smaller than those of the standard UCM.

Is there any one aspect to the Hyper UCM that steel producers particularly value?

Yasunari: That would be the Hyper UCM’s excellent performance in effectively producing extremely hard and light materials, which are vital for decreasing the carbon emissions of cars. For example, a recent TCM upgrade project that involved the replacement of one of the mill’s five 4-Hi stands with a Hyper UCM enabled AHSS production.

Can you share with us what you are currently working on? Any top-secret projects?

Yasunari: The Hyper UCM is operational at three locations, and three more projects are at the design and manufacturing stage. Also, we are working on several pre-projects for a new TCM application that will be used to produce electrical steel sheet, an essential material for hybrid and electric vehicles.