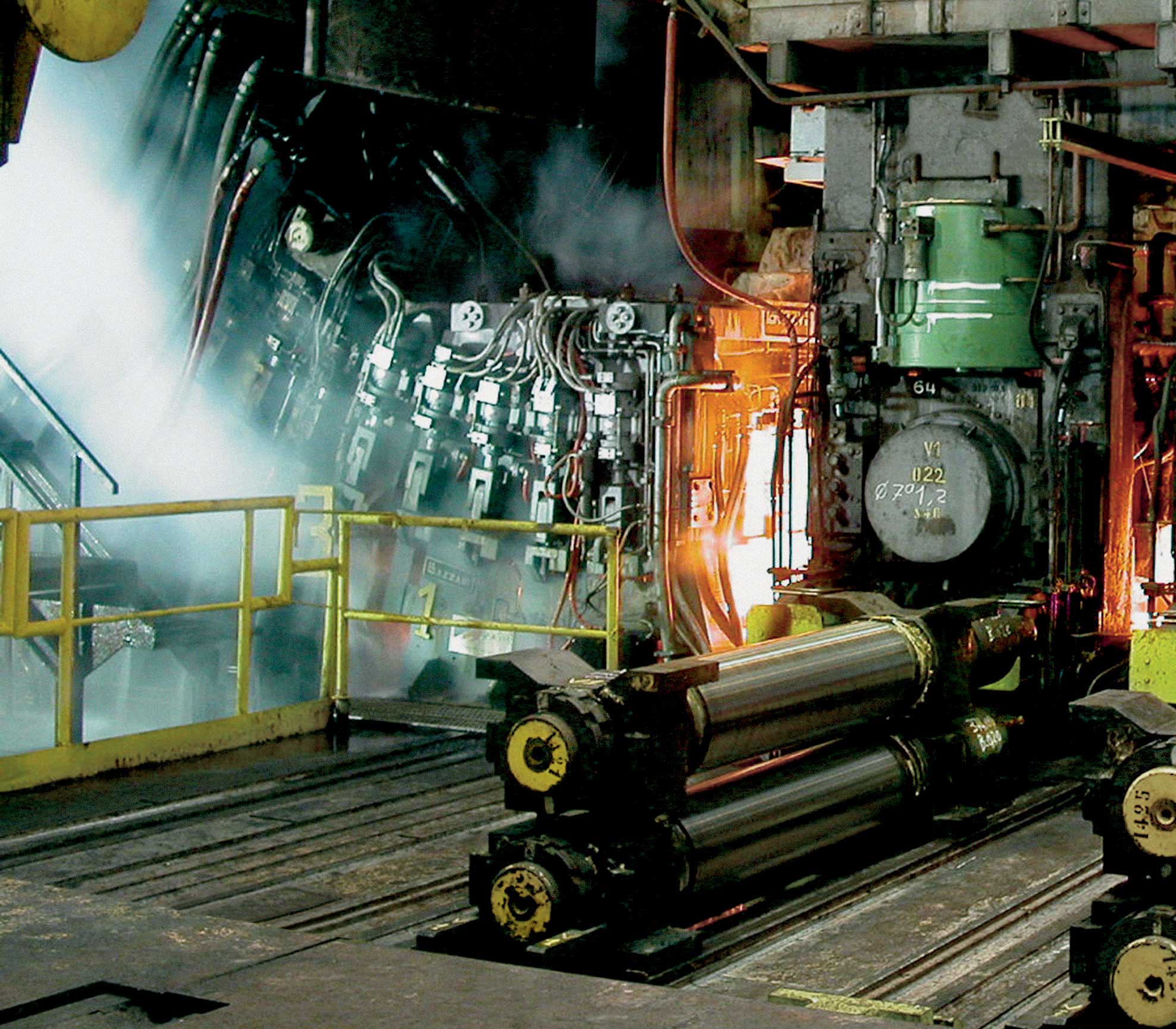

Primetals Technologies has obtained the final acceptance certificate (FAC) for a new type of continuous casting control on an Arvedi ESP casting and rolling line. The “LevCon Bender Anti-Bulging” process patented by Primetals Technologies was commissioned for the first time anywhere in the world. The mold level in the continuous caster is stabilized by means of a controlled oscillation in the distance between opposite rollers in the bending section. This new type of process reduces the “bulging” effect of the strand on the moldlevel at high speeds much more effectively than by simply controlling the mold level via the steel flow into the mold. For the first time ever, it is now possible to compensate moldlevel fluctuations with higher frequencies.

New type of patented mold level control

Primetals Technologies’ “LevCon Bender Anti-Bulging” is a process control for continuous casters and prevents fluctuations of the mold level caused by unsteady strand bulging. This control method counters the “pumping” of the mold level by means of position-controlled oscillations of the strand’s hydraulically movable bending zone. These oscillations support the control of the mold level by the steel flow into the mold. This new process reduces the variations in the steel flow, thereby stabilizing the strand casting process.

Process even stabilizes at high casting speeds

The bulging effect of a strand is greater at high casting speeds, and higher frequencies occur. This makes such control particularly interesting for Arvedi ESP lines, which produces hot strip in a combined, continuous and uninterrupted casting and rolling process. The casting speed can reach more than six metres per minute and is therefore much higher than with “conventional” continuous casters, where it is often below two metres per minute. The new process has also been successfully deployed at low casting speeds.

LevCon Bender Anti-Bulging is a registered trademark of Primetals Technologies in a number of countries.

MORE INFORMATION

Read the full press release and access contact details and other press resources using the following link: www.primetals.com/press-media/news