Metals producer Ege Çelìk Endüstrisi Sanayi ve Ticaret A.Ş. has contracted with Primetals Technologies for upgrades to its wire rod mill in İzmir, Turkey. The addition of a new wire rod outlet will expand its value-added product range for markets in Turkey and Europe, with greater capability for surface finish quality and dimensional tolerance in its wire rod products. Thermomechanical rolling will improve drawability while reducing overall heat treatment costs. Commissioning for the new wire rod outlet is expected in summer 2023.

The new wire rod mill will be capable of rolling rods with a diameter of 5.5 – 26 mm at speeds up to 134 tons per hour, or 120 tons per hour with thermomechanical rolling, using both a 130 mm square and 160 mm square billets. Ege Çelìk operations will produce low, medium, and high carbon steels, along with cold heading quality, and welding wire grades for the automotive and other industries seeking higher-quality products.

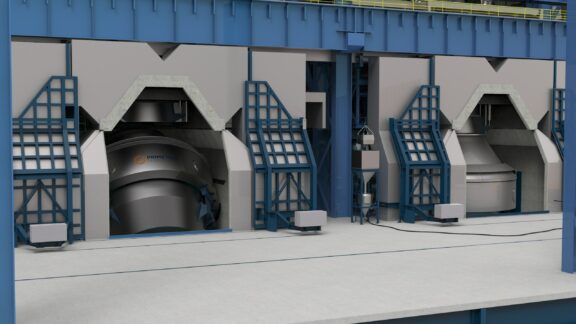

The scope of supply for the contract includes upgrading an existing roughing/intermediate mill with new drives and automation, two roughing mill stands (1H +2V), and a new wire rod outlet with several Morgan products, including an individually driven eDrive 8-stand Vee No-Twist Mill, new inline cooling with an Enhanced Temperature Control System (ETCS), an on/offline reducing/sizing mill, intelligent pinch roll, high speed laying head, and 10½-zone Stelmor conveyor. Coil forming and handling will be accomplished through a vertical/horizontal conveyor system and compactor. A level 2 Process Expert automation package provides reliable material tracking functionality and leads to key performance indicator improvement.

Founded in 1986 with headquarters in Istanbul, Ege Çelìk began steel production in 2001. Ege Çelìk is the leading producer of quality steel wire rod in Turkey and supplies to local and worldwide steel customers.

NO-TWIST and STELMOR are registered trademarks of Primetals Technologies in certain countries.