Magnitogorsk Iron and Steel Works (MMK) held its sixth annual best supplier competition and recognized its most reliable supply chain partners. MMK’s management places great value in this competition since relations with suppliers are one of the key factors for successful future development. An honorary diploma in the category “Leader of Environmental Solutions in Metallurgy” was awarded to Primetals Technologies, for supplying asecondary dedusting system for the BOF melt shop.

The award was presented during a gala event, where Pavel Shilyaev, MMK CEO, thanked the winners for their cooperation. Primetals Technologies is proud to be honored as one of the selected suppliers. Wilhelm Fingerhut, Vice President Environmental Solutions, received the prize: “We would like to thank the MMK management and the project team for their excellent cooperation and this gesture of appreciation inspires and motivates us further. We will continue to complete projects together and ensure that we live up to this award.”

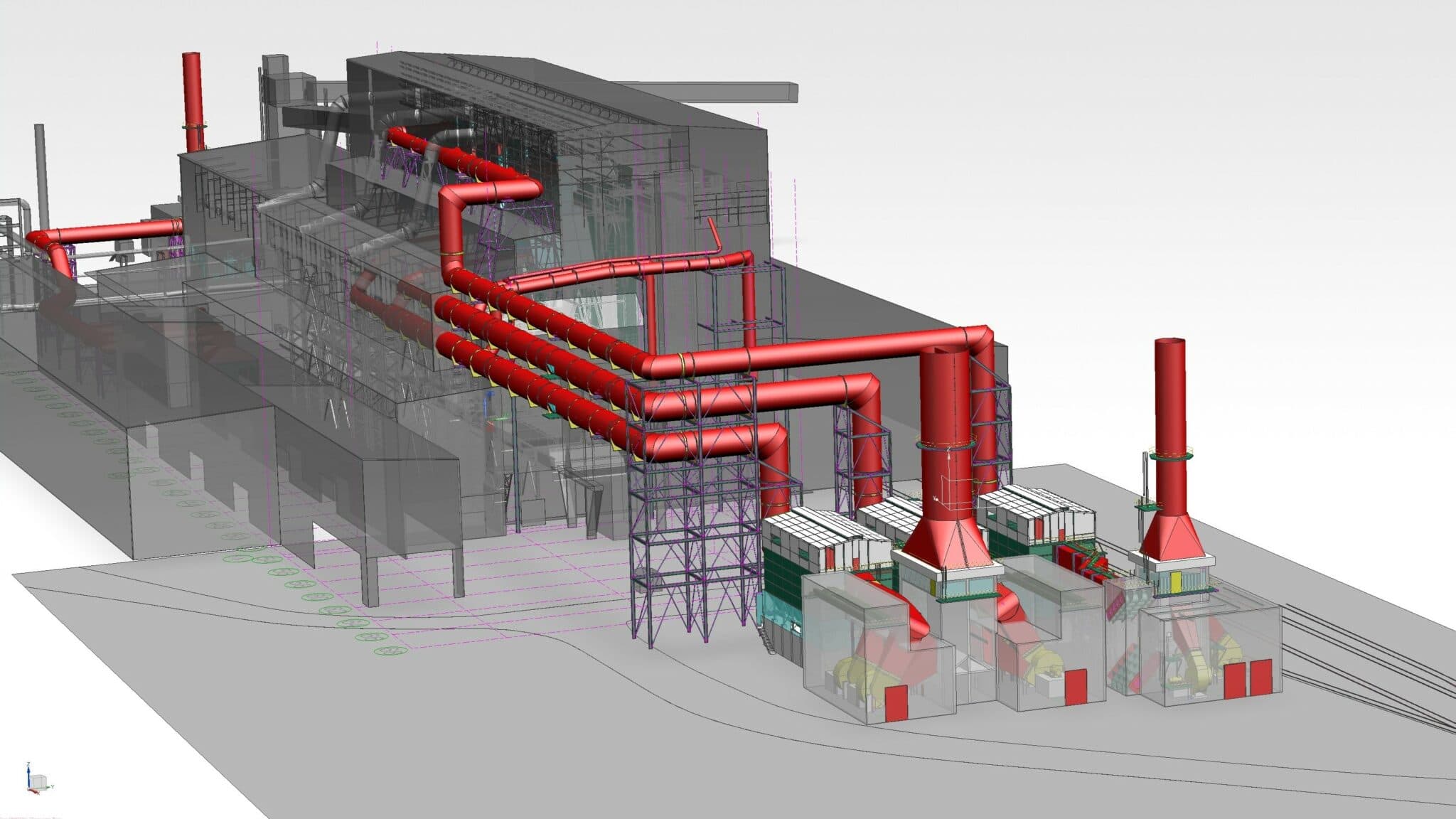

The contract for the secondary dedusting project for the BOF melt shop was signed in early 2020 and is currently under implementation. It is aimed at improving the working conditions inside and outside the steel shop and will bring the city of Magnitogorsk one step closer to a green city by significantly reducing emission levels.

Primetals technologies supplies engineering, equipment, and supervision for the project and startup is scheduled for summer 2022.

The main task of the secondary dedusting system is to efficiently capture dust emissions that occur during the handling and processing of hot metal and liquid steel (e.g., charging, tapping, reladling). The proper design and location of hoods is essential to achieve the highest dust collection efficiency and ensure clean atmospheric conditions inside and outside the steel shop. A major process improvement is the patented Primetals Technologies peak-cooler technology that absorbs temperature peaks during hot-metal charging and reduces the need for additional cooling air. Hence, this innovative technology based on thermal energy storage leads to reduced dilution air demands and reduced off-gas volume flows. This solution reduces investment and operating costs. Additionally, operational safety is improved, and greater productivity is achieved through a higher charging speed. The advanced pulse-jet filter removes dust from the raw gas stream and assures highly efficient dedusting and increased lifetime of filter bags.

Magnitogorsk Iron & Steel Works PJSC is one of the world’s largest steel producers and holds leading positions among Russian steel companies with a total steel production capacity of 11.6 million tons of steel per year. The Company’s assets in Russia represent a large steelmaking complex with a full production cycle, from preparation of iron ore to production of downstream products. MMK produces a wide range of steel products with a predominant share of premium products.

MORE INFORMATION

Read the full press release and access contact details and other press resources using the following link: www.primetals.com/press-media/news