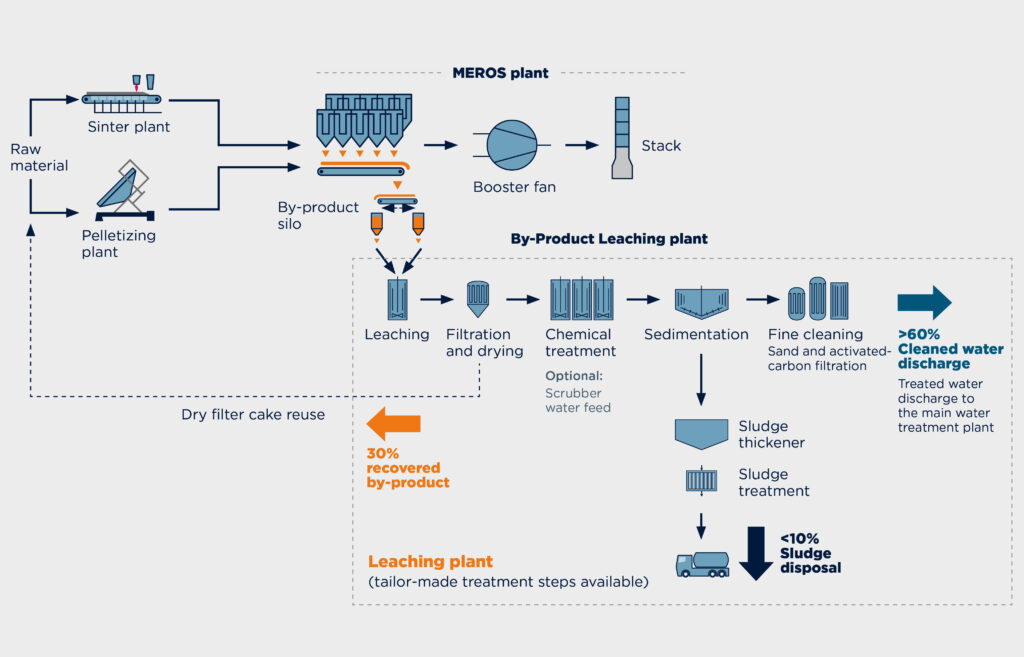

Primetals Technologies’ new By-Product Leaching plant has now begun full operation. It was designed to treat the dust from off-gas cleaning systems such as the sinter-plant oriented MEROS system. By combining these two environmental solutions—MEROS and By-Product Leaching—Primetals Technologies has developed a method of recycling valuable materials for reuse in sinter and pelletizing plants. This innovative setup also reduces carbon emissions and the use of landfills without sacrificing efficiency.

Adapting to current challenges

Countries worldwide have continued to develop and implement various measures and legislation to reduce disposable waste and encourage the reuse of waste material. Following such guidelines, multiple industries, such as the iron and steel industry, use desulfurization (DeSOx) plants like MEROS (Maximized Emissions of Sintering) to improve waste gas emissions. These emission-reduction plants effectively remove harmful substances from the off-gas, capturing sulfur dioxide, dust, and 90 to 99 percent of the dioxins, furans, and heavy metals, which are separated and collected as residue. However, this innovation produces another type of waste in the form of residual dust, which contains high concentrations of heavy metals, harmful naturally occurring compounds, and other toxic substances. Manufacturers must then dispose of the dust from the desulfurization process.

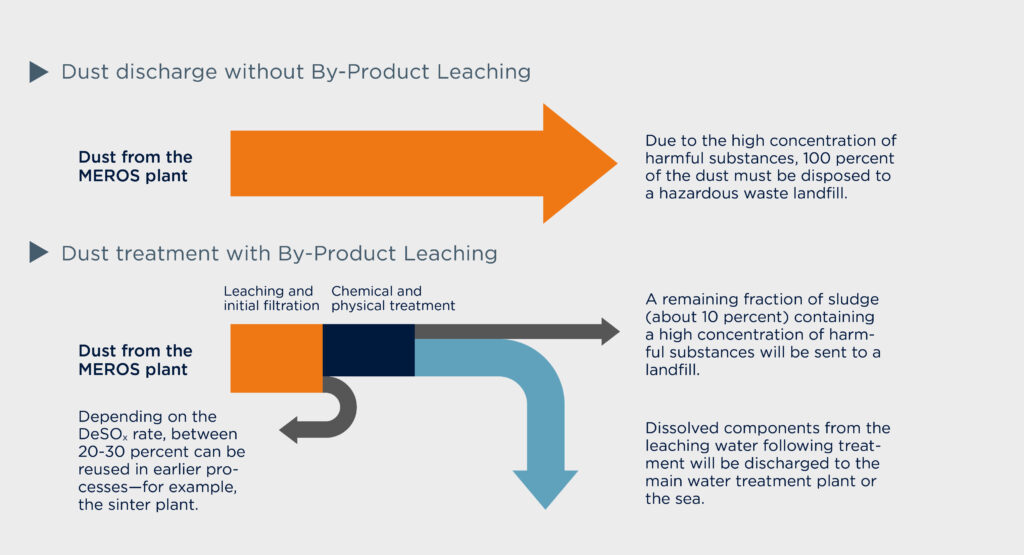

One standard disposal method is sending the dust to a landfill site. However, according to environmental guidelines and based on the dust’s chemical composition, the dust is classified as “toxic waste.” The disposal to landfills is cost-intensive and limited to ever-shrinking hazardous-waste areas. Additionally, the dust must also meet specific requirements before being deposited in a landfill.

Introducing a By-Product Leaching plant in addition to gas-cleaning systems such as MEROS yields several benefits:

- By-Product Leaching takes care of large quantities of dust containing heavy metals, naturally occurring harmful components, and other toxins, concentrated to a fraction of the original residue.

- Designed for the comprehensive recovery and utilization of by-product from dry-dedusting systems

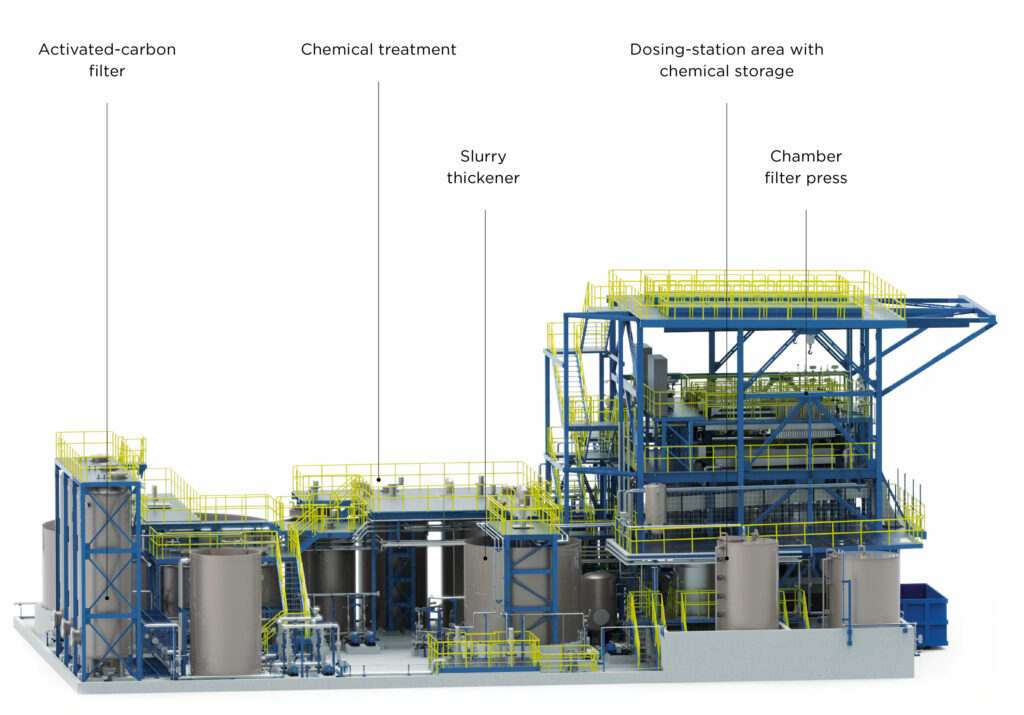

- Tailor-made design and compact layout based on a modular system

- Recovery of up to 90 percent of the by-product, which can then be reused and recycled

- Fulfills “Best Available Technology” requirements

- Adjustable to meet individual legal requirements

- By-Product Leaching plants make a substantial contribution to the circular economy.

One such requirement is the stabilization and solidification of the dust using cement to render the dust immobile. Solidification ensures that rain or high air humidity cannot circulate harmful substances from the dust, polluting the surrounding soil and water. However, the soluble salts in the dust can also affect the long-term stability of the cement block and cause problems with the containment of heavy metals, making this an ineffective long-term solution.

Concrete solidification also requires a high concentration ratio between cement and dust, which reduces the ability to reuse the dust in the future. Using cement also means additional CO2 emissions, producing between 200 to 550 kilograms for each ton of dust. Concrete solidification and the disposal to landfills is the applied method of iron manufacturing—until now.

From theory to innovation

Several scientific papers investigate the possibility of reusing the dust in sinter or pelletizing plants. These papers conclude that direct use of dust is problematic due to the high alkaline concentration. The dust from a dry desulfurization plant contains approximately 44 percent sulfate, 13 percent chloride, 24 percent sodium, and 11 percent potassium. The composition of the dust from a dry desulfurization plant using sodium bicarbonate—i.e. MEROS—, depending on the desulfurization rate, is approximately 67 to 77 percent sodium sulfate, 3 to 8 percent sodium chloride, and 20 to 30 percent suspended solids.

The alkalis—sodium and potassium—have a particularly negative effect on blast furnace performance. These elements decrease the efficiency of the blast furnace’s reduction process, locking the coke’s incineration and building up scaffolds. Thus, the dust requires treatment based on its chemical composition before reuse in sinter or pelletizing plants. Additionally, the type of agent used in the desulfurization process determines how this residue, or dust, needs to be processed after being collected. When using sodium bicarbonate, which is the agent successfully used by the MEROS system, it is important to consider that the by-product after the MEROS plant cannot typically be recycled or reused in other applications, primarily due to its high salt and alkaline concentration.

By implementing a leaching plant after the desulfurization plant, the leaching process separates harmful materials, such as heavy metals and naturally occurring compounds, from the sinter dust. This innovation allows for more than 90 percent of the dust to be treated in an environmentally beneficial way, reutilizing up to 30 percent of materials previously deposited as residuals, recycling up to 70 percent of the dust, which is dissolved in water, used in the treatment process, and reducing deposits in landfills to just 10 percent of the residual dust (see Figure 3).

The leaching plant step by step

In the first step, the dust from a desulfurization plant is thoroughly mixed with water in the leaching tank (Figure 4). The resulting solution consists of suspended solids, including insoluble particles coming from the sinter dust—for example, activated carbon—, and dissolved salts from the dust and desulfurization agent, as well as particles already in the water added during this step.

Once the mixing is complete, the solution is filtered. The main task of the filtering system is the separation of particulate matter from leaching water. The filtered particulate will be washed, dried, and discharged back to the sinter or pelletizing plants. Depending on the desulfurization rate and the efficiency of the electrostatic precipitators, 20 to 30 percent of the undissolved materials from the dust, for example, iron oxide (Fe2O3) and activated carbon, can be reutilized. Following the filtration process, chemical treatment steps, like heavy metal removal, extract harmful substances from the solution. Due to the high concentration of toxic substances, approximately 10 percent of the dust is deposited to a specific landfill in the form of sludge, which results from the chemical cleaning process.

Finally, and in accordance with environmental regulations, the chemically treated water is filtered again with a sand filter and then polished with an activated-carbon filter before being discharged to a wastewater treatment plant or the sea, depending on local conditions and regional emission standards.

The end results

Responding to a worldwide trend of waste-material handling, Primetals Technologies has developed a unique leaching plant that reduces waste material deposits in landfills to just 10 percent of the residual dust and decreases additional carbon emissions by moving away from the use of cement. Used in conjunction with MEROS, Primetals Technologies provides a tailor-made treatment system to recover raw materials, provide environmentally friendly wastewater disposal, and reduce harmful waste material to a small fraction.

The compact layout and modular system allow for a tailor-made design based on the needs of the customer. And by implementing a leaching plant after the desulfurization plant, customers will see a considerable reduction in operational expenditure (OPEX) in the long run, especially considering that disposal costs at landfills will increase as the space for such sites decreases year after year. Not only does the By-Product Leaching system satisfy the fulfillment of Best Available Techniques requirements, but it also decreases overall CO2 emissions and reduces a steel plant’s overall carbon footprint.

Interview with

Dr. Martin Goetz

By-Product Leaching is a novelty in metals production. Dr. Martin Goetz was instrumental in the development of the technology.

How long did it take for you and the team to develop By-Product Leaching?

Goetz: It took several years. Initially, the team at Primetals Technologies developed the concept; then, we collaborated with the University of Natural Resources and Life Sciences, Vienna, Austria, who helped us start up the first plant.

Could a By-Product Leaching plant be built anywhere, or only at seaside locations?

Goetz: The current design does indeed depend on the ability to discharge the brine, which results from the leaching process and is chemically similar to seawater, to the sea. But this limitation will likely disappear. Together with our university partner, we are working on a new concept that would allow for inland operation. This is an important step for Primetals Technologies because about 50 percent of the world’s sinter plants are not located by the sea.

Everyone is talking about green metals production. What contribution can By-Product Leaching make?

Goetz: By-Product Leaching is an important step toward realizing circular-economy principles in steel production. It reduces the amount of by-product sent to landfill by as much as 90 percent. We are also looking to further expand the scope of the solution to include mercury treatment in the future.

MORE INFORMATION

For more on By-Product Recycling from Primetals Technologies click here