The Sequence Impulse Process enhances blast-furnace-based ironmaking and lowers the associated carbon footprint. The technology superimposes periodic bursts of oxygen on the steady flow of oxygen to the furnace, thereby optimizing the conversion behavior of coal and coke particles and takes it one step closer to green ironmaking.

The global challenge faced by all steelmakers to eliminate greenhouse gas (GHG) emissions and to reduce raw material and energy consumption in pursuit of carbon neutrality is well documented. The route to achieving this is less clear and will be different for each producer. With around 7-10 percent of industrial GHG emissions attributed to the steel industry and 70 percent of the total global steel production reliant on thermal reduction via the integrated steelmaking route, replacement of carbon-based fuels will be necessary.

Improvements in the circular economy of steel to increase the availability of high-quality scrap and to support the transition to electric steelmaking as the primary production route are also underway. Hydrogen-powered ironmaking is seen as the natural successor to the blast furnace, with ferrous units being generated in the form of direct-reduced iron. Alternatively, complimentary processes such as carbon capture and storage or utilization could lower the amount of CO2 emitted to the atmosphere. The final picture will likely be a complex combination of these options for many steelmakers as this transformation evolves.

Whilst there appears to be a general acceptance of the global imperative and requirement by steel producers to change, the technologies and especially the infrastructure to do so are not yet fully realized. Availability and utilization of higher proportions of hydrogen, plentiful supplies of cheap “green” energy, high-quality scrap and mass capture and utilization of emissions remain frustratingly distant technical and economically viable options for producers. In each of the routes, there are substantial hurdles—both technologically and commercially—to facilitating a change at pace. This is in addition to what could be considered an overwhelming financial investment.

It is probable that significant undertakings by governments, businesses, and consumers will be required on a global scale to provide both the legislative and commercial drivers to ensure the shift can happen to meet the ambitious, international goals set out. This will take lengthy and protracted negotiation, resulting in extended timescales, to realize the necessary outcomes. What can be concluded from these facts is that the movement to new steelmaking routes is coming, but not today or tomorrow and possibly not within the next decade.

A major transition

Clearly then, the challenge for blast furnace operators to accelerate this transition is immense—but they must continue to produce competitively in the interim. Even though the task seems daunting, it also presents opportunities where significant gains can be made. The blast furnace is the single greatest contributor to the production of GHGs in the process route. As carbon-trading markets continue to develop rapidly, operators are facing increasing cost pressure based on their existing footprint.

Many have already declared their own ambitious plans but must act now. The reality remains that there is desperate need for effective technologies to support the roadmap toward carbon neutrality. Implementing technology that can have a significant impact in the blast furnace therefore represents a major stepping-stone for operators globally.

Whilst the fundamental characteristics of the blast furnace have changed little over the last 100 years or so, designers and operators have implemented incremental developments for the main vessel and process equipment. This has continued to push productivity to ever higher levels; at the same time, it has been possible to reduce the cost of the hot metal produced. Lower fuel and energy requirements combined with optimization of raw-material quality have become paramount.

In the current environment, the costs for carbon emissions, growing awareness of climate targets, and sensitivity to climate-centered topics are increasingly influencing markets and consumers to the extent that every marginal gain allows steel producers to run their plants more competitively. What if that gain could be achieved whilst also complementing and making a significant contribution toward carbon neutral production?

Interview with

Dr. Dirk Gotthelf

Dr. Dirk Gotthelf, Head of thyssenkrupp Steel’s Schwelgern blast-furnace plant, talks about his experience with the Sequence Impulse Process.

What motivated you to consider and then implement the Sequence Impulse Process?

Dr. Gotthelf: The availability of high-quality raw materials is now severely limited. Compromises between quality and cost have become absolutely necessary to ensure that the production process remains economical. This sometimes poses problems that are difficult to overcome with the conventional process-control strategy at the blast furnace. New approaches are inevitable. Helping the blast furnace right at its heart with regular “oxygen injections” is a fantastic idea.

What are the biggest benefits you have seen with the Sequence Impulse Process solution?

Dr. Gotthelf: The task of every blast furnace operator is to produce pig iron at low cost and at high throughput. Due to the more stable furnace behavior and the cost savings on reducing agents, the SIP plant makes a significant contribution to reaching these goals.

Has the technology met or even surpassed your expectations?

Dr. Gotthelf: Since the SIP technology was tested for the first time worldwide on a large blast furnace, I was curious to see what the results would be in terms of operation and cost benefits. The evaluation of the test phase showed great potential for production at lower costs, which for me as the responsible production manager means an important and future-oriented step in the right direction.

A powerful pulse

In a mature process such as blast furnace ironmaking, technology step changes come rarely and are often decades apart. Sequence Impulse Process (or SIP for short), a new technology available from Primetals Technologies, is such a step change.

As the name suggests, SIP technology involves the pulsing of a medium into the blast furnace. That medium is oxygen. The overall equipment required consists of a pressure-reducing station with ring-distribution lines for nitrogen and oxygen, proprietary SIP boxes (the heart of the pulse generation), pulse lines from the SIP boxes to the tuyeres, and a bespoke plant-control system.

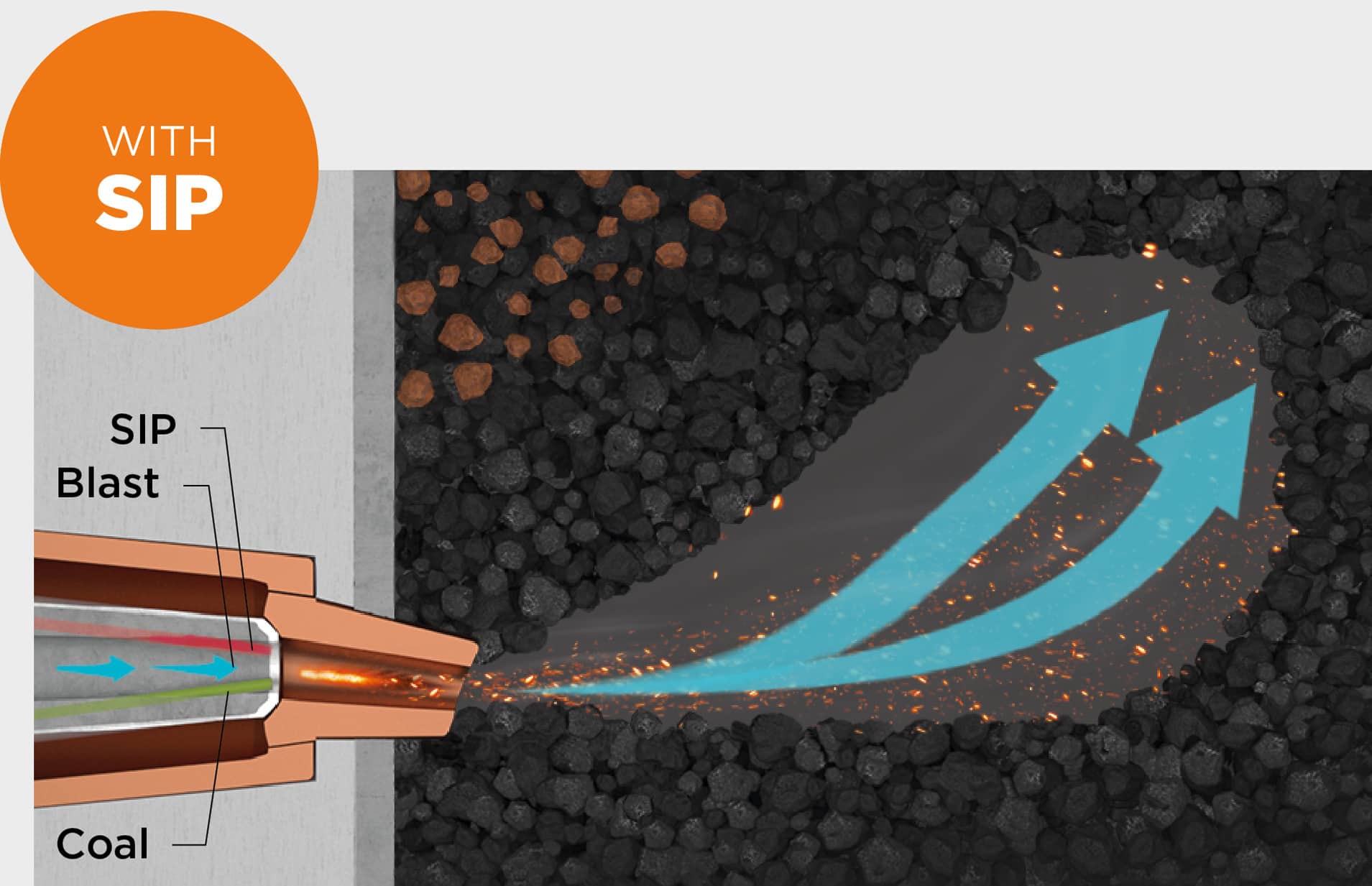

The pulse lines, coming from the SIP boxes, each lead to a dedicated lance, which is inserted into the blowpipe next to the existing coal lance. For cooling, the lance is supplied with a continuous flow of oxygen, the so-called basic load. As it leaves the dedicated lance, the oxygen first meets the carbon stream emerging from the coal lance and is ignited. The pulsed oxygen initially ensures a mixing effect as well as a certain optimization of the conversion behavior of the injected coal.

Periodically, a pulse is generated by the SIP boxes (seen in Figure 1) and then superimposed on the basic oxygen-flow quantity at a pre-determined frequency. A proprietary valve opens and closes very quickly to ensure that a high-energy shock wave reaches the raceway zone of the blast furnace at supersonic speed (Figures 2 and 3). This wave front provides a massive increase in turbulence and thus has a positive effect on the conversion behavior of coal and coke particles—including the uncombusted char that builds up in the lower part of the furnace, forming the “dead-man.”

The control of the system with regard to pulse frequency and the admission of individual tuyeres is freely selectable and depends on how the furnace is operated, which is why it will be matched to the respective furnace during initial setup. The expectation is that this initial setup will be adapted through the day-to-day life of the furnace as is the case with controlling the various other input parameters.

Economically, the use of SIP technology at the blast furnace is expected to allow for more cheap injection coal to be used instead of the more expensive coke. In addition, the reduction of less thermally converted coal particles can be expected to improve throughput and drainage, which ultimately leads to increased production.

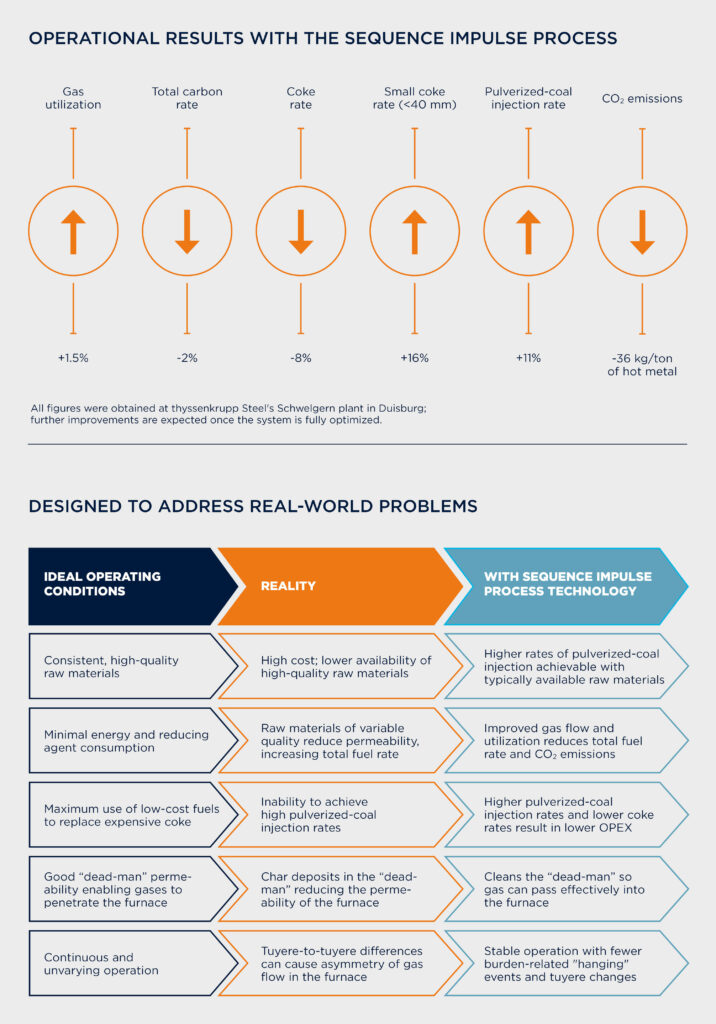

- Improved across-furnace gas distribution and drainage, enhancing production potential

- Improved gas flow into the furnace increases gas utilization, reducing both the total fuel rate and the total CO2 emissions.

- SIP offers a rapid return on investment of under two years for most plants and less than one year for some.

- Substituting coke with higher rates of injected coal results in lower OPEX.

- Reduced carbon-related costs

- The oxygen previously injected via the stoves or oxy-coal injection is repurposed. The total oxygen requirement will be determined by the final pulverized-coal-injection demand.

- More stable furnace operation, compared to conventional coal injection operations. These effects are observed during pulsing:

- Fewer burden-related “hanging” events

- Fewer tuyere changes

- Reduced heat loads, particularly in the lower stack of the furnace

- Higher central-gas temperatures and lower wall-gas temperatures

- Improved furnace permeability and an increase in the small-coke proportion is possible without impacting productivity.

Greener ironmaking

SIP was developed by thyssenkrupp AT.PRO tec and has seen success in foundry cupola furnace applications. Following significant research and development, the first full installation has been operational since December 2020 on blast furnace No. 1 at thyssenkrupp’s Schwelgern steel plant in Duisburg, Germany. SIP delivered a significant shift in raw-material consumption. The improved gas utilization was demonstrated as expected and resulted in a lower overall fuel rate with the consequential reduction in CO2 emissions.

As such, SIP offers blast furnace operators a proven and effective tool in support of the journey to carbon neutrality, bringing essential “green” credentials. Not only does the process enhance the overall OPEX, it also makes furnace operation smoother (see left).

The OPEX benefits lead to a short amortization time, typically within 12-18 months when considering the fuel rate only. This is dependent on production levels as well as internal utility and relative material costs. When also considering the added benefit of reducing the charges related to carbon emissions, the payback time shrinks further—to less than a year, depending upon the carbon levy applied. Primetals Technologies can provide an indicative payback figure to producers based on their specific operational conditions and associated material-utility and carbon costs.

MORE INFORMATION

Learn more about Sequence Impulse Process technology here: Minimize Blast Furnace Operating Costs