ArcelorMittal Belgium’s steel plant in Gent, Belgium started up their new LD converter supplied by Primetals Technologies. ArcelorMittal Belgium serves as part of ArcelorMittal Europe’s Flat Products division, producing goods for the automotive, construction, and household appliance industries.

380-Tons in the Air

The new LD Converter at ArcelorMittal Gent, combining the vessel and trunnion ring amounts to around 380 tons. To accommodate the pre-assembly and avoid possible delays, manufacturing of the LD converter took place at a site in Poland. However, the resulting new vessel and trunnion ring were too large to pass under an existing pipe bridge at the steel plant in Gent. While jumbo jets lift off from airports around the world daily, lifting a 380-ton converter over ten meters into the air is not a typical occurrence and required a 1000-ton crane. With some pre-planning and strategizing, Primetals Technologies met a 35-day timeline allowing for zero interruption to ongoing operations at LD converter No. 3 during the shutdown.

From the start of our project until comissioning we experienced a very professional collaboration with the project team of Primetals Technologies.”

Glenn Gosseye

Project Manager

ArcelorMittal Belgium

Although it was performed in a very challenging environment, we managed to stay within our target of a 35-day shutdown.”

Hannes Seys

Project Engineer

ArcelorMittal Belgium

OPTIMIZED LD CONVERTER FOR GENT

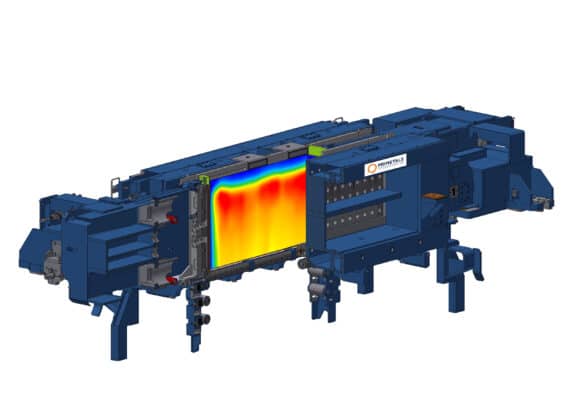

While the delivery and installation of the new LD converter required innovative solutions, a floating 380-ton piece of machinery was not the only thing unique about the new converter at ArcelorMittal Gent. The new LD converter features an optimized shape and the Vaicon Link 2.0—a suspension system that keeps the vessel stable in all directions and allows for thermal expansion. Developed over 20 years ago Vaicon Link has gone through continuous developments at Primetals Technologies and ensures ideal conditions throughout the entire lifetime of the converter. The optimized shape and size mean that heat sizes of 330 makes this LD converter one of the largest in the world.

PROVEN HISTORY

In the end Primetals Technologies strengthened their relationship with ArcelorMittal adding to the long history of cooperation between the two companies. Previous projects have also included the installation of larger LD converters in Spain and Poland. Primetals Technologies supplied everything from the converter and trunnion ring to a maintenance free suspension system, tilting drive, slag shields, parts of the doghouse, and rotary joint and piping in Gent.