Finnish stainless steel producer Outokumpu ordered two new slab casting molds and Mold Expert Fiber systems. Outokumpu’s Tornio site in northwestern Finland will receive the new equipment for its two single-strand slab casters. Using the expertise of specialists at Primetals Technologies, Outokumpu wants to further secure its position as a global market leader in stainless steel.

EXPANDING STEEL VARIETIES

Outokumpu is continuously expanding the variety of stainless steel grades in its product portfolio to include more complex and specialized steels. Meanwhile, the quality levels for standard stainless steel products are also improving as these steels are now used in more demanding applications.

To be able to successfully expand our product portfolio, to further improve product quality, and to ensure safe production, Outokumpu has decided to invest in cutting-edge technology for mold temperature measurement.”

Mika Näätsaari

Project Manager

The new technology provides us with a new type of visualization of the mold. This is of great importance because the mold is where the slab’s surface quality is determined. Also, Mold Expert Fiber gives us the possibility to control the casting process and the solidification of the steel to a greater extent.”

Marko Petäjäjärvi

Development Engineer for Casting

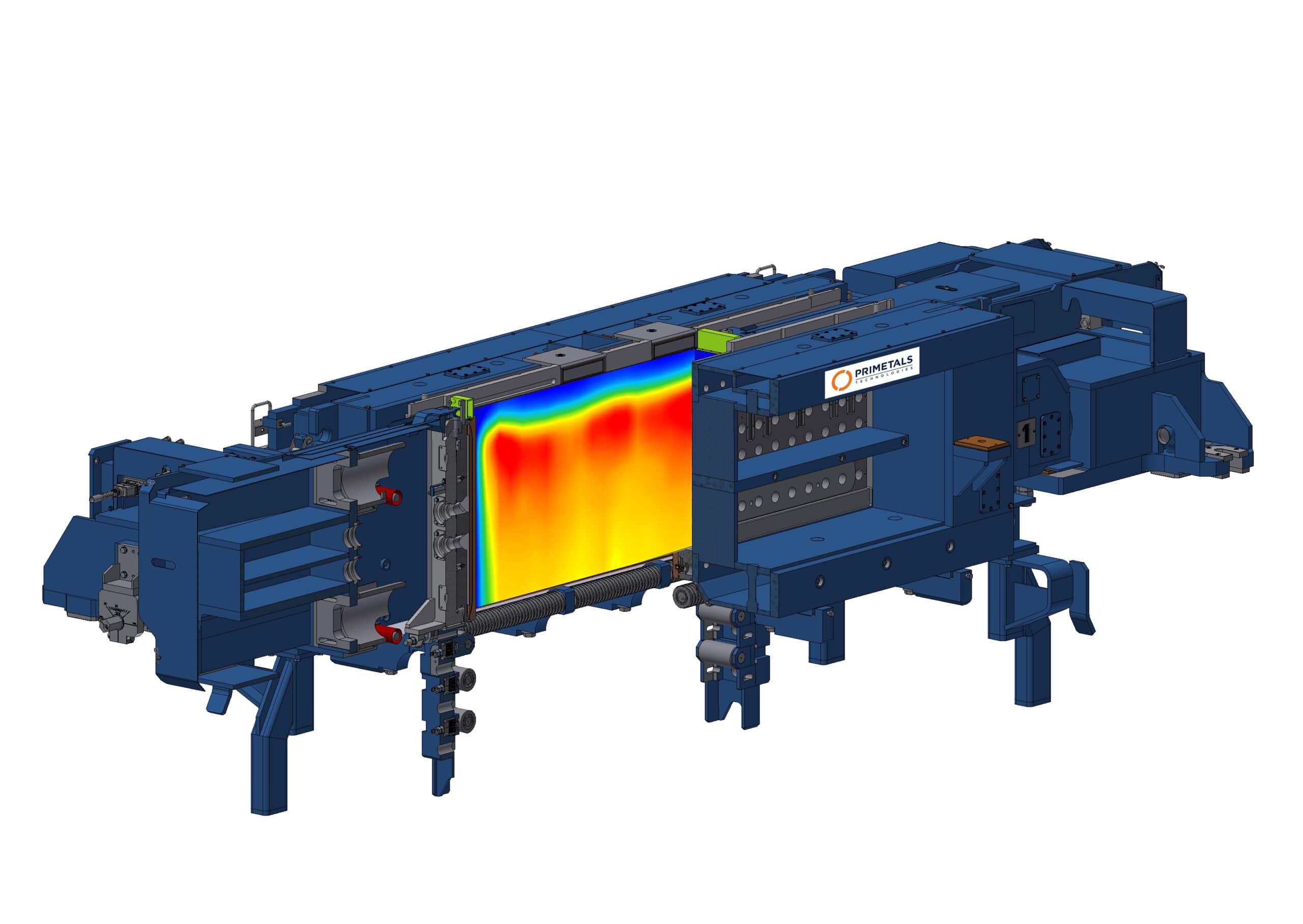

VISUALIZING THE CASTER MOLD

Mold Expert Fiber aims to warn operators of the potential for a caster-mold breakout as early as possible. The system also delivers information that until now was unattainable. For example, Mold Expert Fiber provides data on the exact mold level across the whole width of the mold and the movement of liquid steel inside the mold.

To grasp the comprehensiveness of Mold Expert Fiber, the two new systems for Tornio will include 1,786 measuring points per mold, which is over 30 times more sensors compared with conventional thermocouple measuring. The secret behind the numerous measuring points is Fiber Bragg Gratings (FBG) fiber technology, which use reflected light burned into the fiber. When the temperature changes, they reflect the light differently and these changes can be measured and visualized. As a result, the measuring points produce a real time thermal image of what is happening inside the mold.

“The thermal image shows the meniscus’ shape – ideally it should look like small symmetric waves. However, these waves shouldn’t be too weak nor too intense”, says Martin Schuster, product manager for Mold Expert Fiber at Primetals Technologies.

MORE INFORMATION

Read the full press release and access contact details and other press resources using the following link.