Most of the CO2 emissions in steelmaking come from the blast furnace to reduce iron ore. While still the majority production route today, a new green steel technology developed in collaboration with RHI Magnesita and Primetals Technologies may transform the industry landscape.

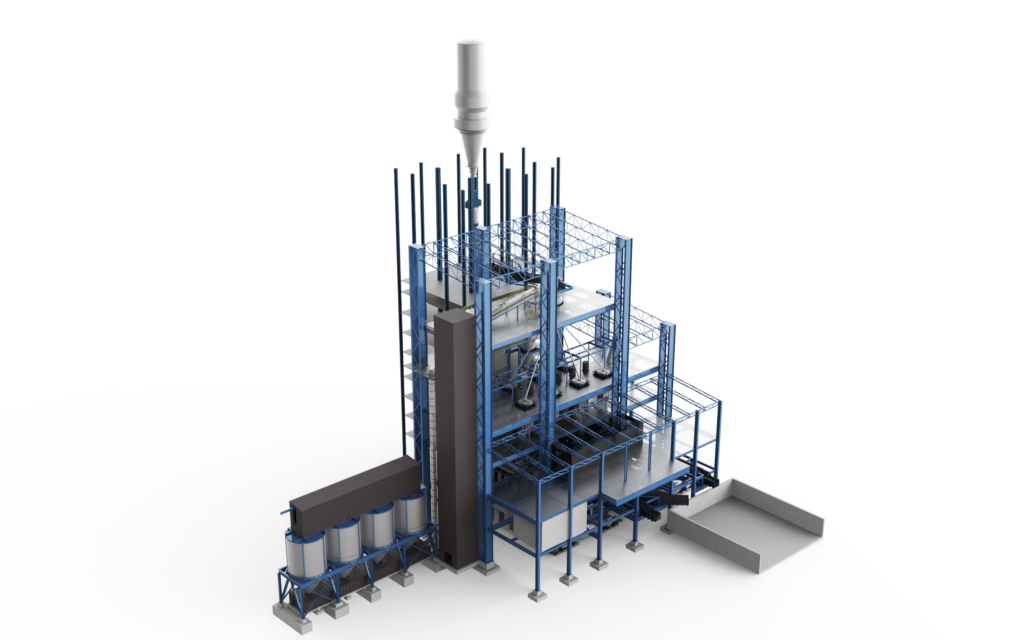

Introducing the Smelter

RHI Magnesita, a global leader in refractory innovations, has helped pioneer a new solution called the Smelter, an electric furnace designed to melt and reduce direct reduced iron (DRI). The immediate benefit of Smelter operations is reducing CO2 to one-sixth of the emissions for the BF-BOF route. The Smelter achieves this by replacing the blast furnace with a direct reduction plant and a Smelter to produce liquid hot metal for the converter. Additionally, the type of slag produced in a Smelter can be recycled for the cement industry, contributing to the circular economy.

If you are serious about green steel, you have to start with the blast furnace processes, i.e., where the CO2 emissions are massive. RHI Magnesita has been working closely with both steel and non-ferrous industries around the world for years. We are proud to be an integral part of the push for the development of green steel production solutions together with Primetals Technologies, not only as a supplier of refractories but also as a technology partner.”

Constantin Beelitz, President Europe, CIS, and Turkey at RHI Magnesita

RHI Magnesita and Primetals Technologies have extensive experience in the development of new technologies. That is an excellent base for successfully developing just the right technology for steel producers who struggle to find a replacement for the blast furnace.”

Gerald Wimmer, Vice President of Converter Steelmaking at Primetals Technologies

Moving Away from the Blast Furnace

Transforming an entire production route may seem challenging for steel producers commonly operating the BF-BOF route. However, two main benefits emerge regarding the operational transition away from the blast furnace. First, during the installation of the Smelter, the BOF can continue production, meaning no changes to the production chain, and producers do not have to renew their certifications. Second, the blast furnace can continue operation until the Smelter is online, meaning production can remain constant. Finally, the Smelter is designed to handle low-grade iron ores, which trade at lower costs than high-grade iron ore, DRI, or hot briquetted iron. Low-cost raw materials mean that producers can offset their expenses by purchasing inexpensive raw materials to achieve the same results as blast furnace operations while improving their carbon footprint.

Long-Term Solution

An essential part of the Smelter is the refractory material, which protects the furnace shell by containing hot metal at temperatures of at least 1500° Celsius. Consisting of bricks, it expands when heated and endures exceptionally high temperatures. The performance of the refractory material is determined by several factors, such as size, quality, mechanical furnace design, and cooling solutions. RHI Magnesita and Primetals Technologies are working together to find the best refractory solution for the Smelter and ensure high productivity and a long lifetime.

We will contribute our know-how and experience to the development of the Smelter in a way that both customers and the environment will benefit.”

Constantin Beelitz, President Europe, CIS, and Turkey at RHI Magnesita

We are confident that direct reduction will play a crucial role in the reduction of CO2 emissions from iron and steel production. With the Smelter, we are developing a new technology for direct reduction-based steel production that will allow for the sue of low-grade iron ore, which make up the majority of iron ore globally.”

Gerald Wimmer, Vice President of Converter Steelmaking at Primetals Technologies

Developing a Better Future

RHI Magnesita and Primetals Technologies anticipate that steel producers will continue to invest in green steel technology. In this case, the Smelter is a sensible and environmentally friendly option to extend the lifetime of existing integrated steel plants with just a few minor adjustments. With their collaboration, RHI and Magnesita have run several simulations and are preparing the Smelter for the market.

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.