Amidst growing demands for eco-friendly production routes and persistent actions for a more sustainable future, a new term in the steel industry has emerged: “green steel.” While the terminology may differ—from net-zero to low-carbon steel—green steel encompasses an array of sustainable topics, from electrification and hydrogen eco-systems and direct reduction to the circular economy and carbon capture, utilization, and storage. This article examines the state of the steel industry and the term “green steel” as both a trend toward sustainability in steel production and a low-carbon end product.

From carbon lean to net-zero, it seems all but clear that the preoccupation of the steel industry with decarbonization is more than a short-term fad. Above all, this represents a positive trend for the steel sector regarding its environmental impact. Worldwide producers are making their stance on the environment known by creating a new line of products under the banner of “green steel” and adapting their production routes to meet stringent environmental regulations, effectively “greening” their entire production chain. One thing is clear, green steel is here to stay. But what is green steel exactly?

Meeting Growing Demands

Perhaps the most telling feature of green steel has been a focus on carbon emissions. Decarbonization in the steel industry has gained much attention for various reasons. Currently, the steel industry contributes to approximately eight percent of global CO2 emissions. Decarbonization is key to a sustainable future for the heavy industry. With 1,951 million tons of crude steel produced in 2021 at nearly 1.85 tons of CO2 per ton of crude steel, signs point to the vast potential for improvement regarding decarbonization. Additionally, with the demand for steel increasing, including in sustainable energy sectors, such as wind and solar power, producers must find a way to meet market demands while reducing their environmental impact. Beyond meeting rapidly growing market demands, producers also must factor in various strategies regarding emergent policies for environmental regulations, which are not always straightforward or sustainable. Currently, producers must remain flexible and conscious of these changes until a clear strategy emerges.

Governments and organizations are implementing measures to make improving the environmental impact of steel production both essential and attractive. Among these strategies are emission trading systems designed to ensure that steel producers pay for the CO2 they emit. Producers will have to account for their direct emissions (Scope 1) using the definition of “scope emissions.” They may also have to account for the amount of CO2 generated indirectly via energy purchase (Scope 2) or indirect value chain emissions for upstream and downstream activities (Scope 3) from the purchase of raw materials to logistics and transport. In Cremona and Triest, Italy, Acciaieria Arvedi became the first certified net-zero CO2 emissions steel mill for Scope 1 and Scope 2 emissions. By decreasing the amount of CO2 emissions early on, producers avoid unnecessary costs as their capacity increases. The demand placed on the steel industry to lower CO2 emissions is apparent for the future, but this is only one aspect of green steel and the industry’s sustainable future.

Creating a Sustainable Future

Due to its ease of calculability, carbon emissions have remained a focus for environmental groups and governments worldwide, but this is only one aspect of sustainability. In 2015, the U.N. established a set of targets known as the Sustainable Development Goals as part of the 2030 Agenda for Sustainable Development. The plan is a culmination of initiatives from the U.N. to improve sustainability worldwide. These initiatives focus on all pillars of sustainability, including the social, environmental, and economic factors that contribute to lessening inequality and enhancing prosperity. For the steel industry, this also means adopting technologies and practices that broadly protect the environment and contribute to sustainable goals.

Without a globally recognized industry standard for sustainable steel and green steel, several organizations have emerged to help the industry define and reduce its environmental impact. One example is the non-profit organization ReponsibleSteel. Recognizing a need for standardization across the globe, from mining operations to deliverable products in the steel industry, ResponsibleSteel aims to ensure consumers that their steel has been responsibly sourced and produced. Their certification involves a series of audits provided by third-party organizations to avoid bias, which are then verified by ResponsibleSteel. The results of their certificates are kept transparent to establish trust in their organization and its ability to verify a sustainable and responsible site. In April of 2022, ResponsibleSteel awarded its first certification in North America to Big River Steel in Osceola, Arkansas, U.S.A.

As previously mentioned, green steel has primarily been the focus of decarbonization efforts in the steel industry. However, it stands to reason that “greening” production extends well beyond decarbonization and involves improved technologies that benefit the circular economy, the reduction of various other pollutants, improved energy consumption, resource efficiency and water usage, and the protection of human rights. Thus, sustainable steel production, a “green” steel production, is based on fundamental sustainability principles. While all these aspects of “green” production appear clear, where does green steel as a product fit into sustainability?

What is Green Steel?

The steel industry is not alone in its pursuit of sustainability and decarbonization. Parts of the U.N. Sustainable Development Goals extend to technology, infrastructure, and energy productivity improvements, which closely involve the steel industry. Steel producers are catering their products to contribute to a “greener” world. One area of interest for green steel producers is e-mobility and the automotive industry.

As electric vehicles become more and more prevalent and standard vehicles seek to decrease their mass, the demand for lighter, stronger steels will also increase. (For more on the green future of e-mobility and the rolling technologies capable of producing electrical steel grades, see “Meeting Demand: Electrical Steel and Mobility”) Electric vehicles demand particular steel grades known as “electrical steels” and increase the amount of silicon steel found in cars. The market demand for this type of steel is expected to grow in the coming years as individual mobility strategies shift away from fossil fuels.

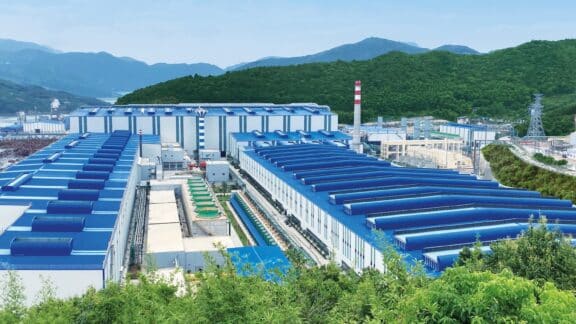

Green steel production encompasses various aspects of eco-friendly production, from water and off-gas treatment to decarbonization and improved energy efficiency.

Beyond green steel as a base material for the automotive industry, “low-carbon” steel and greener steel production will benefit from the increased demand for steel to strengthen public transit and energy infrastructures for a more sustainable future. As green steel is both a significant addition to steel producers’ portfolios and a positive part of a transition toward a more sustainable future for the steel industry and society, what is Primetals Technologies contributing to this development?

Green Steel at Primetals Technologies

In May 2022, Primetals Technologies launched a new organization called “Green Steel.” The initiative seeks to identify synergies between parts of the portfolio of Primetals Technologies and incorporate technologies from Mitsubishi Heavy Industries. What’s most important to the approach to green steel at Primetals

Technologies is the ability to adapt to the various demands and requirements of steel producers worldwide. Currently, there is no internationally recognized standard for green steel production. However, governmental initiatives to regulate steel production to make it more environmentally friendly are emerging around the globe.

SOCIAL

The social aspect of sustainability encompasses the human element of society and how it interacts with the environment and the economy. From forming and preserving communities to advocating for equality and human rights, sustainability impacts the social dimension of our society in that we satisfy basic human needs for all persons across the globe.

ECONOMIC

Much of the discourse around sustainability pays particular attention to the human element—for instance, diversity and human rights—or the ecological, e.g., environmental regulations. However, economic development is also a crucial aspect of sustainability. In terms of sustainability, the economy is not merely about sustaining growth but striking a balance between financial motivations and the other two pillars. In the past, more attention has been paid to economic growth, while human suffering and environmental destruction have remained.

ENVIRONMENTAL

Often written as ecological, environmental sustainability is perhaps the most well-known aspect of sustainability and plays a crucial role in everyday reference to sustainability practices. The environment is vital to supporting social and economic sustainability. In both economic and social contexts, an environment that contributes to the health of society is well-protected and sustainably managed. A healthy environment provides the conditions to meet all our needs for generations.

For green steel production, Primetals Technologies can adapt to meet varying standards and address all aspects of eco-friendly production, including water treatment, off-gas treatment, CO2 reduction, and more. Additionally, solutions covering all aspects of the production chain can be revamped to produce premium products that may then be labeled “green steel.“ Concerning digitally enhanced decarbonization, a vast array of automation and digitalization packages contribute to sustainable goals, including safety. These solutions support green steel production by optimizing processes, reducing waste, and increasing energy efficiency.

As the transition toward a more environmentally friendly production route for the steel industry continues, it will require cooperation beyond geographic and industrial borders. Being a company with a broad portfolio to enhance steel production and locations across the globe, Primetals Technologies is proud to be a part of the industry transition toward green steel. Alongside the “Mission Net Zero“ initiative of Mitsubishi Heavy Industries Group, which targets carbon neutrality by 2040, Primetals Technologies is poised to help industry leaders realize their own goals as they transition to green steel production and pioneer a more sustainable future for the steel industry.

MORE INFORAMTION

Learn more about Green Steel at Primetals Technologies here.