Shanghai, with a population of 26 million, is less of a city and more of a world of its own. Its many skyscrapers, temples, and museums, along with its famous riverside “The Bund,” all contribute to a unique flavor that is both hyper-modern and classy. Countless corporations, especially from the financial sector, have chosen Shanghai for their headquarters. With the steel industry not being far away, Primetals Technologies naturally is also present in the metropolis. Metals Magazine’s Dr. Tom Widter reports.

It is early morning on a Monday in August 2023 when I catch the first glimpse of Shanghai. The outskirts of the massive city, which boasts a population of the same size as all of Australia, suddenly appear in the window as the Boeing descends. Having never been to China before, I eagerly try to spot any unusual city characteristics and am struck by the sense of orderliness with which the buildings are arranged. They are surrounded by a sizable amount of vegetation—I can make out many parks and tree-filled streets mixing with enormous constructions of steel and concrete.

A minute later, Shanghai’s famous skyscrapers come into view. They appear tiny from this distance. As I will later see up-close, they are anything but and highly diverse in shape and exterior design. Before too long, we land, and I must prepare for the more arduous part of the journey—getting through the airport’s immigration and ID checks. It turns out that these hurdles are similar to what you can expect when travelling to the U.S.A., but I notice a distinct difference in mentality as I have my fingerprints and photo taken, calmly following the officers’ instructions. All procedures are done in the most respectful of ways.

The company driver already awaits me at the Arrivals area. It is about a one-hour trip to the company location. The drive presents another welcome opportunity to familiarize myself with the city. I soon conclude that Shanghai is beyond impressive when it comes to architectural boldness and diversity—from Pudong airport, with its curved concrete look, to high-rises and the more traditional Chinese-style buildings, there is a lot to absorb. As we reach the company location in Shanghai’s Minhang district, I am again astonished by the considerable number of trees and green spaces framing the enormous office building. While the overall feel of the area is extremely modern, the greenery adds a flair of timelessness, calmness, and class.

Meeting the Shanghai Team

I enter the building and immediately bump into Liu Yan Ting, a colleague who works in Communications and has helped to orchestrate my visit. In our everyday conversations, she goes by the name of “Lavinia.” Liu explains to me that it is common practice in Shanghai for people to choose an “English name” at some point in their lives—usually their late teens. In most cases, they stick with it. For foreigners, this convention greatly simplifies referring to acquaintances and colleagues; simultaneously, the often exquisite English names add a professional touch to interactions in the business context.

Liu takes me to Tomislav Koledic, CEO of Primetals Technologies China, who gives me a crash course on everything taking place at the location. I learn that his team supports steel producers beyond their Chinese-based operations, in the wider Southeast Asia region. Countries like Vietnam, Thailand, and Indonesia are expected to contribute to considerable growth going forward. China itself is still an highly relevant market, as it leads the world in steel-production capacity and output at around 50 percent of global production. It is also the single-largest consumer of finished steel goods, with half of everything made worldwide being used in China.

There has been a recent shift, though, away from commodity steels for the construction industry and toward flat products destined, for instance, for the automotive sector. Silicon steels, as hard to manufacture as they are, have become a highly desirable portfolio item, Koledic tells me. The technologies provided by Primetals Technologies for the manufacture of these demanding grades have received much praise in China, he says: “I am glad to see just how highly Chinese producers regard our cold-rolling technologies, such as our Hyper UCM and 20-high mill.” I ask Koledic what other solutions are currently in high demand. He replies that there are many, and points to four particularly relevant areas: “We are seeing great interest in Arvedi Endless Strip Production, electric steelmaking, caster upgrade packages, and in our services.”

Next-Level Services

The services side of things has gained even more relevance of late, and Koledic asks Xu Xiao Lin, Head of Metallurgical Services China, to join our conversation. Much like Koledic, Xu has extensive international experience. He recently returned from a nine-year assignment in the U.S.A. to help expand the scope and footprint of the services offered, far beyond China’s borders. Xu believes that digital solutions will continue to change the face of services as we know them and improve quality across the board: “The trend toward Industry 4.0 is a major lever in our expansion strategy,” says Xu. “Winning new business in China heavily depends on progress made in R&D. Our expertise in digital solutions will be essential for staying ahead of our competition.” Xu is determined to ensure that his team never ceases to promote innovation.

Primetals Technologies currently operates three services workshops in China, but one of them is as central to the company’s operations as it is close to the Shanghai location. “Our workshop in Changxing has just entered ‘Phase Two,’” says Xu. “This means that we have added a second hall and are now executing even more tasks, and of a wider range.” The extension was strategically planned and is progressing nicely, which is illustrated by the growing list of high-end equipment available to the workshop staff as well as by the rising employee count. “Would you like to tour the workshop?” asks Xu. This, of course, is not an offer that I would want to turn down.

Automation and Green Steel

Before I embark on the two-hour journey to Changxing, I speak with Qiu Rong Bin, who is Chief Engineer at the Shanghai location’s engineering center. The center specializes in hot-rolling automation, and Qiu informs me that the lion’s share of his work focuses on project-based basic and detail engineering. Having been at Primetals Technologies for two decades, Qiu has seen many advances in automation design and is proud of the crucial role China and his location have played over the years.

I ask Qiu what it takes to pioneer new automation solutions in China. He feels that the country offers an advantageous environment to anyone wanting to innovate in the fields of science and technology. “Chinese people are generally open to collaboration, which lets you get faster results. There is, for instance, a direct exchange of ideas about how to best implement artificial intelligence,” says Qiu. To him, AI is not necessarily a revolution but an effective tool—if one’s aim is to increase efficiency and reduce the need for human labor. He tells me that one of Primetals Technologies’ recent innovations, the Central Operation Cockpit, which enables steel producers to oversee and orchestrate all production-related tasks from a single room, was first requested by a Chinese customer. Qiu’s thoughts confirm an impression I have had since I landed in China—that the country is pioneering many new things and may soon overtake some of the nations it previously looked up to, in terms of vigor and ingenuity.

Our discussion about AI makes me wonder what Qiu thinks of the “autonomous plant”—the idea that steel plants could eventually operate completely on their own, without interacting with humans. “It’s an important concept,” he says diplomatically, “especially if you work in automation. But I think that people will always be needed, they will simply be doing different tasks.” What other trends matter to Qiu? He refers to the transition to green steel: “Carbon emissions are a complex issue, especially if you consider aspects that go beyond the core production process.” When I ask Qiu if there is an inventor he particularly admires, he picks Yuan Longping, who developed the first hybrid rice varieties in the 1970s and spearheaded the Green Revolution of agriculture. Now, the time has come for the steel industry to undergo its own green transformation.

Employees of Primetals Technologies share many passions, such as pioneering new solutions for their customers. But every location also has unique qualities. In this section, we catch a glimpse of what makes Shanghai so special.

I am proud of China’s 5000-year history, of Shanghai as a city that has seen much empowerment over the last three decades, and of the opportunities you get if you work hard.”

Wang Xiao Jie

Controlling Manager

Our economy has made so much progress in the last 30 years that I have a better life today than my parents did. Products from China are exported to the whole world.”

Ma Xiao Xiao

Quality Manager

China is very diverse, with 56 different nations living together in peace. We share a long, continuous history, making China stand out globally. Chinese are modest and industrious.”

Sunchang Zhenshu

Head of Legal Counsel

Our food and languages vary from region to region. Within Shanghai alone, you will find different dialects. We are extremely friendly and welcoming to foreigners.”

Wang Ming Jin

Senior Supply Chain Manager

I am really fond of our public transport system. China’s cell phone infrastructure is world-leading, allowing us to enjoy transparent and convenient mobile payment options.”

Zhang Li

Human Resources Consultant

“Are you ready to depart?” Our colleague Dai Zhe Hao has entered the room and informs me that the car is waiting to take us to Changxing. We leave during rush hour, as daylight fades. For the first 30 minutes of our journey, we discuss car brands. Many of the vehicles driving alongside us were made by manufacturers that I have never heard of before. About 50–60 percent are electric, the highest share I have never seen before. “The EV market in China has grown fast, with new models getting better and better … it is a hyper-competitive field, which is great for Chinese consumers,” comments Dai.

The Changxing Workshop

The next morning, as we arrive at the workshop, Dai and I are welcomed by Zhu Hui Gang. Zhu has been with Primetals Technologies for 23 years and now has the role of Production Manager at the Changxing workshop. I tell Zhu just how impressed I am with the size of the place. “But Tom,” Zhu says, “this hall is only part of the overall site.” It turns out that “Phase Two,” the new extension, corresponds with yet another section nearby. In total, the area covers 9000 square meters. “We will soon be installing photovoltaic cells on our roofs,” Zhu says as we walk around the premises. “They will provide about 60 percent of the power we require for operation.”

Before Dai and I can tour the workshop area, we need to be fitted with safety equipment and clothing, which Zhu has already prepared for us in the site’s offices. As he takes us there, we pass by engineering, sales, quality control, order management, and procurement staff, all using the early hours to take care of the most pressing tasks. Zhu informs us of the scope covered by the admin team, pointing out the close collaboration with the Shanghai company location. With some anticipation, we finally proceed to enter the workshop area. Zhu tells us to expect a wide variety of spare parts, all of which are currently either being reconditioned or made from scratch. “We add new parts to our portfolio each year,” he says. Over the course of our tour—which ends up lasting several hours—we encounter parts destined for long-rolling mills, Arvedi ESP lines, continuous casters, the EAF Quantum, and many other production units.

Interview with

Qiu Rong Bin

Qiu Rong Bin is Chief Engineer and runs the

Primetals Technologies engineering center for

hot-rolling automation at the Shanghai office.

What is changing in the field of hot-rolling

automation?

Qiu Rong Bin: Models and sensors are playing a more central role these days, enabling functions that were previously unachievable. As a result, operators and maintenance staff can work more efficiently and focus on the essential tasks.

Is there any recent automation project that

stood out to you, and why?

Qiu: There are many interesting projects but one that pops out is a Chinese-owned plant located in Malaysia. The producer has the vision to build a reference-class hot-rolling mill with a Central Operation Cockpit and next-level automation. The Cockpit will be windowless, with the whole plant being controlled from screens and via the interface.

Have you ever been surprised by a technological development in the steel industry?

Qiu: Arvedi ESP was a surprise to me when it first entered the market. The fact that you could make a hot-rolled coil on a production line only 180 meters in length was revolutionary. This innovation rests on engineering from many different disciplines.

Is there any technological area outside of metals production that fascinates you?

Qiu: Self-driving cars are making substantial progress, and there are many open testing areas here in Shanghai. A number of self-driving buses are already in operation.

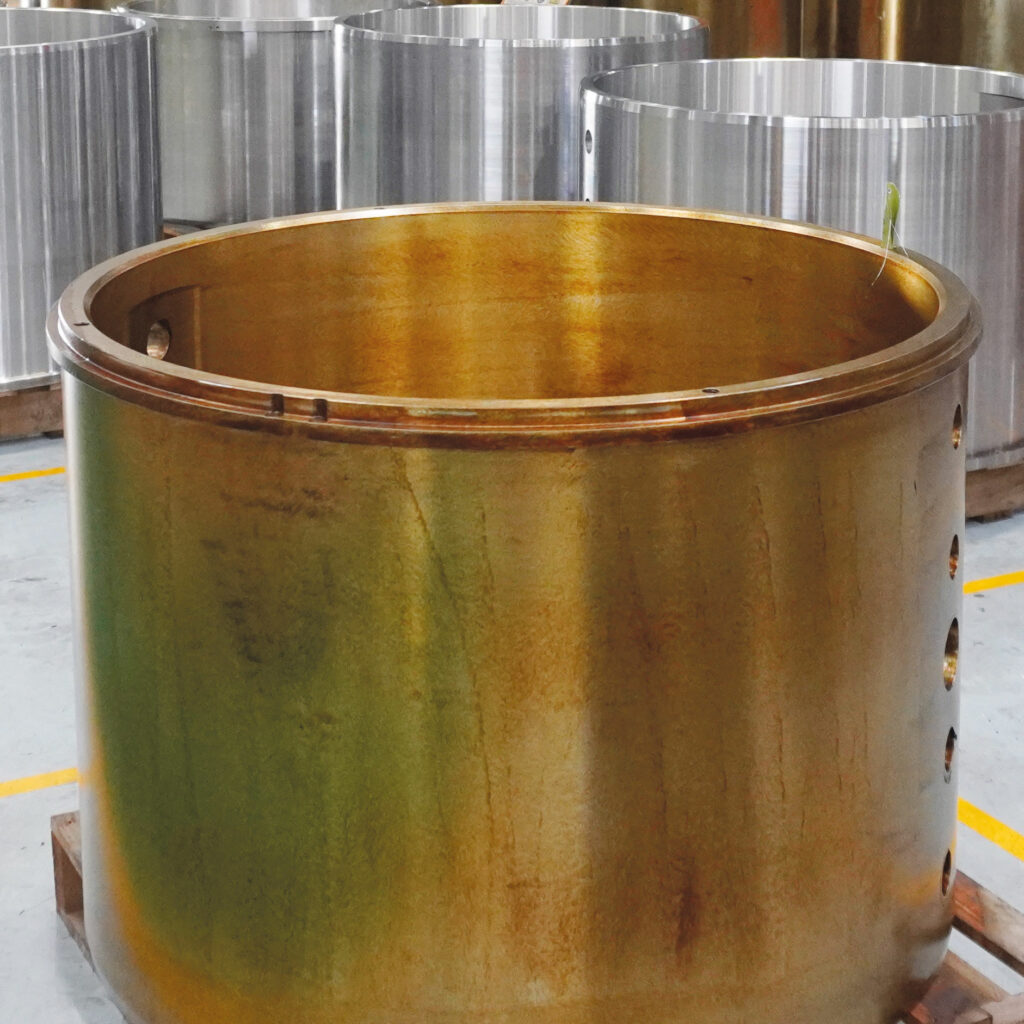

High-end rolling solutions are very prominent and Morgoil oil-film bearings, says Zhu, are a fine example of a solution that enjoys an excellent reputation among Chinese producers. I see first-hand the many manufacturing steps required for bushings, an essential component of Morgoil bearings. The bearing assembly area is equally revealing: I find it exhilarating to touching the newly made or just-assembled parts. In fact, I am almost shocked by the degree of precision to which the parts were made. Some of the smaller components have a feel to them that I have only experienced with jewelry. “What are these for?” I ask Zhu Hui Gang. “These are parts of a flinger belonging to a long-rolling finishing mill,” the workshop’s mastermind answers. “We make 400 of them per month, with only one—highly dedicated and hard-working—operator.”

Having toured a number of workshops, I get the impression that the machines available at Changxing are top-notch. Zhu nods: “We use a lot of top-level equipment, some of which is extremely rare.” He takes Dai and me to a grinding machine, a truly massive apparatus. “There are only five of these, worldwide,” he says. “New employees often tell me that they find their work enjoyable thanks to our outstanding gear.” So how does Zhu and his team achieve consistent results? Many machines, he says, provide operators with detailed digital instructions based on highly structured processes. CNC machines, for example, are programmed via online manuals and QR codes. Plus, everyone starting out at Changxing receives extensive, multi-year training. Zhu also makes a point of applauding workers who excel at certain tasks—and of mentoring those who require more guidance. Workers are trained to be versatile, and Zhu provides us with the basics on what it takes to operate cutting, drilling, turning, milling, curling, and grinding machines … it is a lot to take in. By the time Dai and I finally head back to Shanghai, we are both so full of new impressions that neither of us feels the urge to engage in conversation until we’ve reached our destination.

And yet, the Shanghai company location still offers more to be discovered. In addition to metallurgical services and advanced automation solutions, it also serves as a global procurement hub. Back at the offices, I sit down with Yoshinori Kamii, who has made it his mission to enable Primetals Technologies project managers from across the globe to tap into the potential of Chinese manufacturing prowess. The “China Procurement Center,” or “CPC” for short, has built close relationships with select suppliers to ensure on-time delivery of mechanical equipment for CAPEX projects large andsmall. As part of the setup, the CPC team sends supervisors to each of the key suppliers, with the aim of evaluating performance, availability, and quality of equipment, as well as pricing. The increase in transparency helps to eliminate procurement bottlenecks, reduce reliance on single-sourcing, and increase negotiation power. “It is great to see more and more Primetals Technologies locations profit from efficiency gains because of the CPC’s contribution,” says Kamii.

Showing Your Commitment

There is one fundamental reason why Chinese manufacturing has reached incredible levels of sophistication in recent years: it is the mentality of the Chinese people—full of ambition, dedication, and the desire to build a better future for themselves and their country. I notice their determination again and again over the course of my one-week stay. Wang Xiao Jie, who works as controlling manager at the Shanghai location, calls his younger self “a very common child.” Wang’s parents encouraged their son to “study and work hard.” He always followed their advice in their honor. Today, he is proud of the fact that his country and his city, which he greatly identifies with, enabled him to become “self-driving”—a self-made man. Speaking with Wang, I get the sense that personal identity in China is tied to both, your own achievements and those of your community and larger society.

Wang’s account is echoed in my concluding conversation with CEO Tomislav Koledic. “What drives China’s success is the entrepreneurial spirit of its people,” he confirms. Having lived in many different countries, Koledic has found it essential to open himself up to new perspectives and to immerse himself in the culture of a region, so that he can begin to understand the local mentality on a deeper level. He feels that this openness allowed him to mature and grow—as an individual and a leader. There seems to be a natural fit between Koledic’s mindset and that of his staff: “I have found that if you show your commitment, people will follow,” says the CEO when asked about his leadership style. He finds that his emphasis on mutual respect in relationships, both professional and private, is serving him well in Shanghai. As for the long-term outlook for the country of China, what is Koledic’s expectation? With conviction, he says, “China has become one of the key world powers because of the dedicated, hard-working nature of its people. Their optimism will carry on.”