German steel producer Hüttenwerke Krupp Mannesmann (HKM) ordered a tailor-made BOF relining machine to replace a 30-year-old, outdated machine at HKM’s steel plant in Duisburg, Germany. Owned by Salzgitter, Thyssenkrupp, and Vallourec, HKM operates an integrated plant in Duisburg, producing intermediate products for the processing industry. HKM produces four million tons of liquid steel annually and has approximately 3,000 employees.

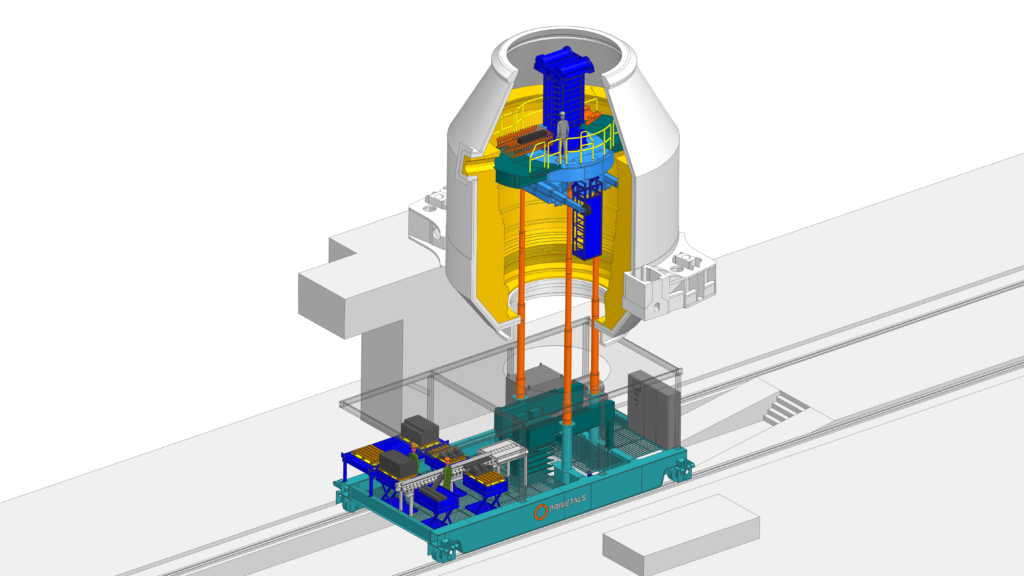

HKM’s tailor-made solution from Primetals Technologies is designed with features such as staff elevators and tailor-made solutions for brick logistics. Primetals Technologies will engineer, manufacture, implement, and provide advisory services for installing and startup the new relining machine.

Relining Logistics and Safety

After a comprehensive study of HKM’s needs, including state-of-the-art ergonomics, access via a separate elevator, and an automated working platform, Primetals Technologies developed HKM’s tailor-made solution. With occupational health in mind, personnel working inside the converter vessel will no longer need to lift the bricks thanks to a semi-automatic system. Two magazine lifts transport the bricks from the depalletizing station into the converter. A robotic device called the brick manipulator automatically discharges the bricks from the magazine onto an extendable roller table. A staff elevator also allows personnel to access the relining platform.

The new machine caters to HKM’s moveable converters, with the relining procedure occurring on a separate relining stand. Once in place, the relining machine is inserted into the converter and fully retracts upon completion.

A detailed safety concept will improve occupational safety during the relining procedure. For example, the design includes a solution for emergency rescue and an emergency power unit for use in the event of a power failure.

The engineering and testing phases will take place in Austria in partnership with leading suppliers and partners. Once manufacturing is completed, the machine will be pre-assembled and tested at the workshop before being transported to Germany.

HKM’s New Relining Machine

- Base frame with a traction drive and a transverse thrust mechanism

- Height-adjustable rotating work platform

- Automatically expandable platform extensions

- Staff elevator

- Refractory brick feeding and depalletizing station

- Automatic brick magazine lift for up to ten bricks

- Brick manipulator solution, including roller table on the working platform

- Automation system

- Emergency power unit

MORE INFORMATION

Click here to read the full press release, access contact details, and find other press resources.