This post is also available in: 简体中文 (Chinese (Simplified))

With more than 90 direct-reduction plants installed and commissioned since 1971, Midrex is the world’s most proven and reliable technology for the production of direct-reduced iron (DRI). Midrex plants account for approximately two thirds of all DRI on a worldwide basis and about 80% of all DRI produced in shaft-type furnaces. Based on these achievements, Midrex technology continues to set the standards for excellence in this dynamic field of ironmaking.

Two of the world’s largest Midrex hot-briquetted iron (HBI) plants recently started commercial production. On September 27, 2016, a 2 million t/a facility—the largest plant module of its type—went into operation at voestalpine Texas LLC, Corpus Christi, in the state of Texas, U.S.A. At Lebedinskiy GOK III in Gubkin, Russia, a 1.8 million t/a HBI plant module—the second largest in the world—produced its first iron briquettes on March 11, 2017. The plants operate at or above their nominal capacity and reliably produce iron briquettes that meet the highest-quality standards.

Both HBI plants share a number of similar features, yet differ in various design details to meet the local production demands and climatic conditions. The Texas plant was built to cope with hot, humid, and muggy summers and strong winds from the Gulf of Mexico, while the Gubkin plant must withstand the cold and icy winters in Russia. Thanks to a highly adaptive technological basis, Midrex plants can be flexibly engineered to perform at their optimum in any type of environment.

Joint engineering

Both the Corpus Christi and Gubkin HBI facilities were engineered by a consortium comprising Primetals Technologies and Midrex Technologies. The project scope included the supply of mechanical and electrical equipment, steel structure, piping, ductwork, as well as training and advisory services. The production capacities and plant configurations of both plants are also similar. A 7.15-meter-diameter Midrex shaft furnace and a 6-row reformer were installed, differing only in the number of installed reformer bays (20 vs. 18 bays). The latest design concepts were also applied for the major equipment items that include:

- Seven state-of-the-art briquetting machines and two cooling conveyors outfitted with a spray-water system for improved HBI quality

- Centrifugal compressors placed in the process gas loop to minimize the consumption of electricity and to improve the operational flexibility of the process gas compressors

- An iron oxide coating system for enhanced production output and product quality

- Environmentally friendly burners for heating the reformer box

- Wet and dry dedusting systems designed to minimize dust emissions

- Elevated top gas pressures to increase furnace productivity

- Heat-recovery units to preheat different gas streams and save energy

Plant Specifications:

Furnace type: Midrex Megamod

Annual capacity: 2 million t/a HBI

Input material: Direct-reduction-grade iron-oxide pellets purchased on the world market

Inner diameter of reduction furnace: 7.15 m

Number of reformer bays 20

HBI metallization: Minimum of 93%

Carbon content: 1.5% C

Other plant features:

- 7 briquetting presses, including a hot DRI fines recycling system

- 2 HBI cooling conveyors

- Increased top gas pressure for higher furnace productivity

- Seawater cooling circuit

- Oxide-coating system

- Ferrous-material briquetting system

- Heat recovery system

Plant start-up:

The first briquette from the Midrex HBI plant at voestalpine Texas LLC was produced in late September 2016. All required performance tests were successfully completed by February 11, 2017. The Corpus Christi plant represents North America’s first HBI merchant HBI facility.

Plant Specifications:

Furnace type: Midrex Megamod

Annual capacity: 1.8 million t/a HBI

Input material: 100% Lebedinskiy GOK iron oxide pellets produced from company-owned open-pit iron ore mine

Inner diameter of reduction furnace: 7.15 m

Number of reformer bays 18

HBI metallization: Minimum of 93%

Carbon content: 1.5% C

Other plant features:

- 7 briquetting presses

- 2 HBI cooling conveyors

- Increased top gas pressure for higher furnace productivity

- Oxide coating system

- Fresh water cooling circuit

- Heat-recovery system

Plant start-up:

The first HBI product from the Lebedinskiy GOK plant was produced in March 2017. The performance guarantee tests (PGT) were completed two months later by May 13, 2017. The Gubkin plant represents Russia’s largest HBI production facility.

Two plants, similar but different

Lebedinskiy GOK produces iron ore pellets from its own pelletizing plant. The pellets are used as a charge material for its direct-reduction facilities. The voestalpine Texas plant operates on the basis of high-quality DR grade iron oxide pellets sourced on the global market.

Resulting from the contrary environments where the two HBI plants were installed, they are also characterized by various differences in their design and configuration. The Russian plant was integrated into the existing production operations of Lebedinskiy GOK, while the Texas plant was constructed on a greenfield site—a former cotton field.

The applied norms and standards also differ. While both plants were engineered according to the metric system, the process information shown on the screens in the control room is in metric units in Russia and imperial units in the U.S. The plants are engineered to perform according to the prevailing climatic conditions—from extreme hot to extreme cold ambient temperatures.

Different water sources are used for process water and cooling applications. At the Texas site, a reverse-osmosis system is applied to generate the required make-up water for the process, and seawater cooling towers and heat exchangers are used to cool the water in the plant water circuits. Fresh water is the source of both the process make-up water and the cooling water at the Gubkin plant.

Lebedinskiy GOK produces HBI for the world market. The briquettes are transported from the works site to external markets by means of rail transport. A train-loading station was part of the supply scope. Approximately half of the HBI from the voestalpine Texas works is consumed in the steelworks of voestalpine in Europe. The other half is sold mostly to North American steel producers. HBI from the Corpus Christi facility leaves the plant via ocean ships.

The performance tests of both plants were successfully passed within a very short time period. All performance targets were met, and most of them even exceeded.

Setting performance benchmarks

Regardless of the environmental conditions where they are installed, Midrex plants are designed for performance. The process is well proven, dependable, and reliably produces an iron product with a high degree of metallization that is ideally suited for the manufacture of highest quality steel grades. Thanks to the use of natural gas or other metallurgical plant process gases, the carbon footprint of Midrex direct-reduction plants is significantly lower than metallurgical processes based on the combustion of coal or coke.

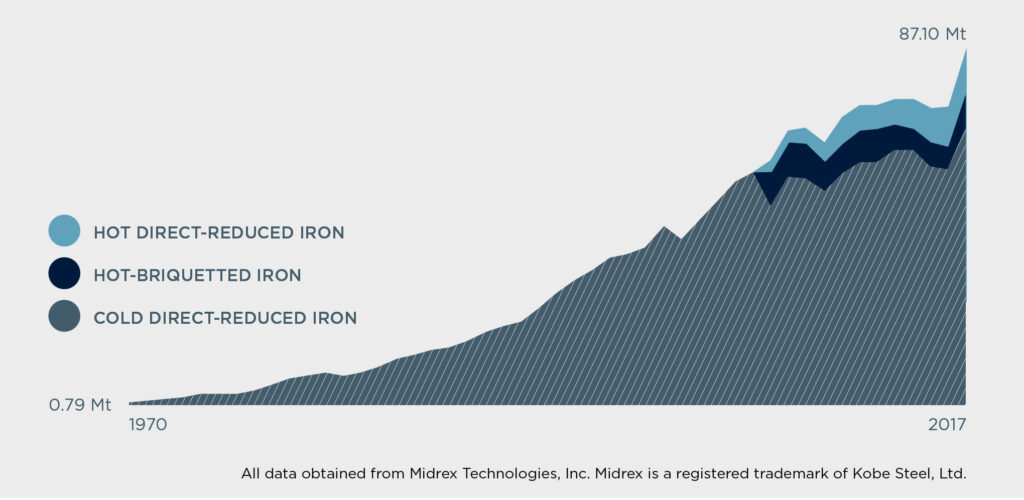

Worldwide DRI production is expected to rise significantly over the next decade. Producers like the fact that DRI can be used as input material with both EAFs and blast-furnaces. DRI can also be easily transported. In 2016 alone, production rose by 14 million tons.

Interview with

Oleg Mikhailov

Interview with Oleg Mikhailov, Managing Director of the mining and ore-beneficiation complex at Lebedinskiy GOK

What were the main reasons behind your company’s decision to invest in a new Midrex HBI plant?

Mikhailov: We are the only European producer of HBI and one of the three largest HBI producers in the world. We already had two HBI plants and the strategy of Lebedinskiy GOK and the entire company Metalloinvest was to diversify and further increase the production of HBI to 4.5 million tons per year.

Why was the consortium comprising Primetals Technologies and Midrex selected as the main partner for this project?

Mikhailov: We already implemented an HBI plant project together with this consortium with good results and a positive partnership history. When we compared the efficiency and operational figures of different plant types, it was an easy decision in favor of Midrex technology. The plants are reliable and user-friendly, and they offer considerable development potential for the future.

What were the main challenges that had to be dealt with during the course of this project?

Mikhailov: First of all, it was coordinating more than a dozen different companies involved with engineering, planning, securing permissions, production solutions, environmental matters, and also safety measures so that they all work together toward a common goal. Secondly, there were more than one thousand people on the construction site, so you can imagine what was involved in coordinating so many people. Then the entire production chain had to be reorganized—we had performed a grand-scale modernization of the ore preparation plant and the pelletizing plant. Commissioning took place in winter at temperatures below zero, which, according to consortium colleagues, had never been done before. But we managed to successfully complete everything together and achieved good results.

Does the installed HBI plant meet your expectations in terms of operational reliability and flexibility?

Mikhailov: On March 11, 2017, we produced the first briquette. Within three months, our specialists and the specialists from Midrex and Primetals Technologies were able to ramp up the plant’s production curve to nominal capacity. All of the target figures were met. I’m sure that with this plant we will be able to exceed its design capacity within two years.

Has the investment in a new HBI plant allowed your company to increase its market share for this product and to enter new market segments?

Mikhailov: Yes, definitely. We have become a production leader of commercial hot-briquetted iron. Our goal was not only to excel in the international market, but also to increase our production share in Russia, and we have made the progress that we wanted to make.

How would you characterize the cooperation with Primetals Technologies?

Mikhailov: We were always able to work well together and to resolve any issues that arose during project implementation. In my opinion, the Primetals Technologies staff are very good problem solvers. The fact that we were able to build this plant complex within one and a half years is a major credit to them. I would therefore like to thank Primetals Technologies for the excellent job done. I hope that we will be able to work together again one day on some other project.