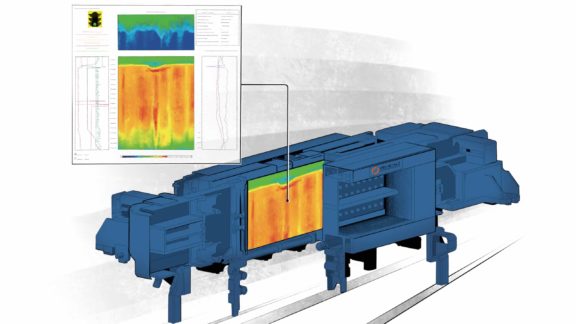

Quality Expert is a computer-aided quality-control system for all types of continuous casters. It is designed to determine the definitions necessary for quality-related process parameters, to track data during production, and to predict the quality of cast products so that potentially defective products can be separated.

It provides plant operators with online quality alerts and a preview of the quality of the casting strands in the machine. Quality Expert comes in two editions with either basic or comprehensive product-quality rating capabilities.

The online quality-control functions are configured in the Maintenance and Simulation System. The flexible rule editor enables end users to adapt or add quality rules without the support of specialized software engineers. Rule systems for predicting the quality of product-defect types (cleanliness, surface quality, inner quality) can be configured. The Quality Expert then evaluates quality rules online and displays the resulting quality rating. The quality previews are available for hot strands currently being cast and for products already cut, along with a root cause explanation of the quality rating. The knowledge-base component means that Quality Expert is easy to configure, enabling process engineers to react quickly to changing quality demands and production requirements. Quality Expert records quality-critical process data at high resolution as it is transmitted from the basic automation system and process computers. All tracked data and calculation results can be transferred from the Quality Expert’s production module to a solution called the Discovery system, which is dedicated to the long-term archiving and evaluation of tracked data in accordance with ISO 9001 standards. Quality Expert represents a milestone in improving quality control in continuous casting. Cost savings can be achieved by avoiding product inspection and conditioning activities, thereby minimizing material losses and handling costs.