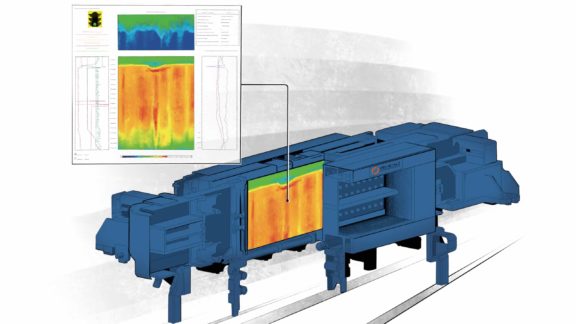

The Nozzle Expert helps to detect clogged nozzles and broken hoses in all types of continuous casting machines, and ensures that the strand is uniformly cooled during the continuous casting process. The steel is cooled by spraying water onto the strand through nozzles. To avoid surface defects and possible product downgrading caused by clogged nozzles or ruptured or jammed hoses, the Nozzle Expert automatically monitors the condition of the nozzles during the casting process.

The Nozzle Expert features online and offline monitoring. In online mode, calculations begin automatically with the “Start Cast” signal, and the condition of the nozzles is monitored throughout the casting process. In offline mode, the secondary cooling system can be tested by manually activating the Nozzle Expert during casting breaks, with the advantage that any problems with the nozzles can be detected and repaired before the casting process is re-started. In idle mode, the Nozzle Expert can perform a more detailed check because proper water-flow rates can be selected. During a manual check, the water-flow rates cover the full range from minimum to maximum flow, and the performance of the controllers can be examined. The results are documented in a report, which shows the states of all cooling zones and contains a detailed section for each zone with the time trends of all relevant zone data. The Nozzle Expert is based on statistical models and indicates the ratio of clogged nozzles in each zone. Therefore, operators only have to inspect zones for which an alarm is generated. This highly efficient setup minimizes maintenance efforts and reduces the hours involved in checking nozzle status.