Calculation of the 3D temperature profile of the strand requires accurate knowledge of the thermodynamic properties of steel, which includes enthalpy, solid fraction, density, and conductivity as a function of the steel temperature.

However, in most cases the metallurgist does not know these thermophysical properties in advance. In order to obtain an approximation of these values, steel grades are normally grouped together and an average chemical analysis is made of each steel group. The various material properties of the respective steel groups are then experimentally determined. The resulting data is then manually entered into the Maintenance and Simulation System (MSS) tool by the metallurgist, which is a time-consuming procedure. However, casting operations show that there can be a difference in the point of final strand solidification of half a meter and more when different steel grades are cast within a particular steel group. This fact underlines the need for a process tool capable of performing online calculations of the actual steel-grade properties.

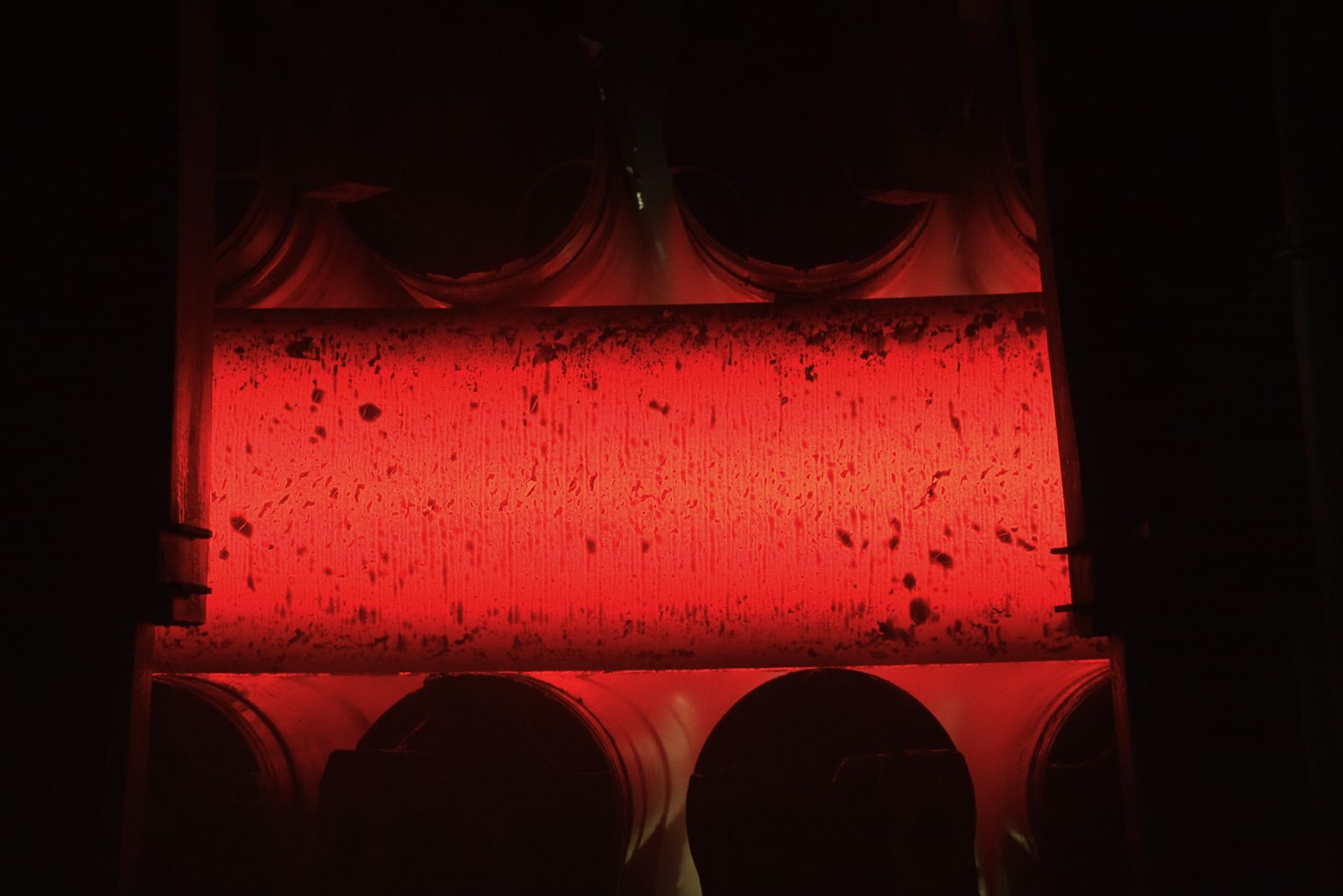

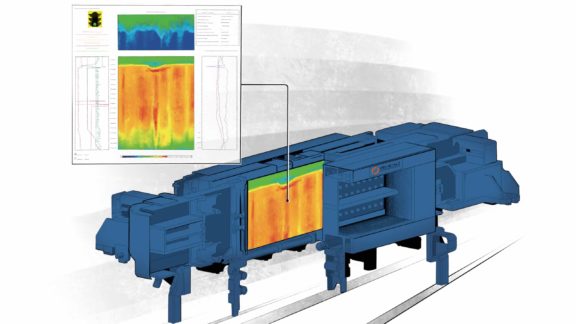

With the DynaPhase software model, the thermodynamic properties of each steel grade are calculated online on the basis of the relative proportions of coexisting steel phases at a particular temperature. This information is entered into the Dynacs 3D system, which then maps a 3D temperature profile of the strand. The combination of the DynaPhase and Dynacs 3D process models is unparalleled in the industry.

Number of references: 14 since the introduction of this process model in 2013; 14 additional projects will be implemented in 2018 and 2019.