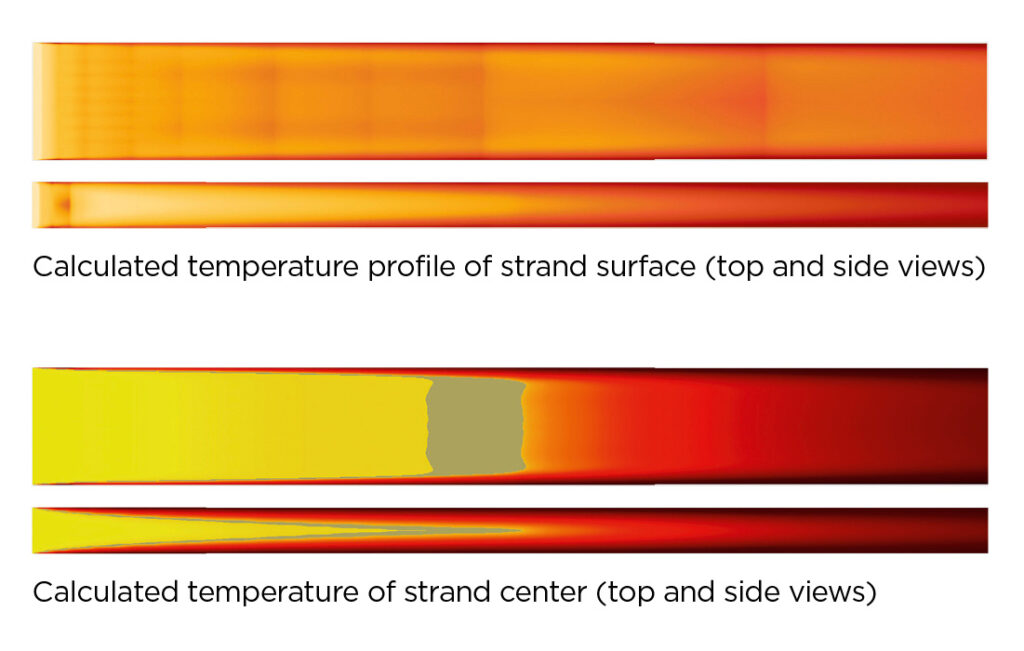

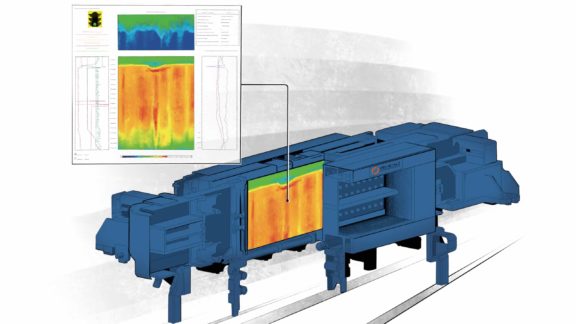

Thanks to continuous improvements in computer performance, it is now possible to calculate the temperature at any point within a continuously cast strand in real time. Using this information, the Dynacs 3D process model generates detailed 3D temperature profiles that serve as the basis for totally optimized secondary cooling.

The model solves the heat-transfer equation and takes into account temperature-dependent steel density as well as slab thickness and width at a specific position. Heat transfer from surface radiation and natural convection, and heat transfer to the rolls and the spray water is accurately calculated by Dynacs 3D. The model is applicable for both spray-water cooling and air-mist cooling. It also considers the spray-distribution pattern of the nozzles and the actual spray-water temperature.

Thanks to the precise temperature calculations, individual control of water-flow rates and precise positioning of each cooling nozzle with movable 3D spray nozzles are possible. In this way, the targeted strand-surface temperature values are obtained for homogeneous surface cooling and excellent surface quality.

Knowledge of the temperature distribution along and throughout the strand during casting enables the point of final strand solidification to be accurately determined. Optimized soft-reduction can then be performed beforehand to eliminate center-strand porosity. The combination of the Dynacs 3D and DynaPhase process models also serves as a powerful off-line simulation tool for defining the cooling strategies required for the development of new steel grades.

Number of references: installed in more than 60 casters since the introduction of this process model in 2011; 17 additional projects will be implemented in 2018 and 2019.