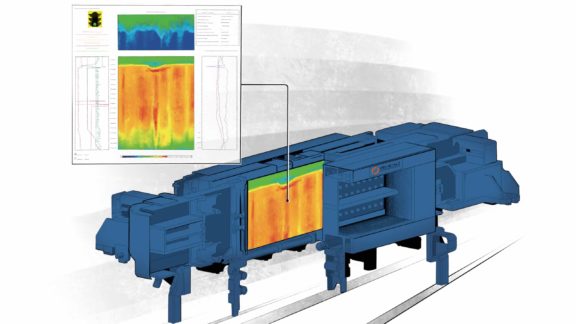

OsciChecker Wireless is designed to analyze the behavior of oscillators on continuous casting machines and accordingly optimizes maintenance time, reduces downtime, minimizes strand breakouts, and improves surface quality through optimized lubrication conditions at the mold. The device enables plant operators to measure mold stroke and oscillation frequency, as well as sinusoidal and non-sinusoidal movements. It can be used for straight and curved oscillations, and is suitable for slab, bloom, and billet casting machines.

OsciChecker Wireless comprises up to four measuring sensors, a calibration plate, a measurement unit, a data acquisition and evaluation program, and a measuring box in a heavy-duty protection case. It picks up mold movement spatially using capacitive acceleration sensors placed on the mold, pointing horizontally in casting direction and vertically in stroke direction. The sensors, which can be charged via standard USB or mini-USB cable, feature magnetic fixings to ensure stable measurements and a high level of accuracy. Once placed on the mold or the oscillator, the measurement sequence can be started. Movement in and perpendicular to the casting direction can be detected, as well as negative strip time and percentage. OsciChecker Wireless is also able to spot total harmonic distortion of the oscillation frequency.

The compact yet powerful OsciChecker Wireless is suitable for the measurement of oscillator movement in all three directions and for the storage and visualization of measurement data in 3D. A wireless data connection ensures maximum user comfort and flexibility, entirely eliminating the need for cumbersome cables. The system is transportable, which means it can be carried easily between strands, and predictive maintenance means that shutdowns and breakouts can be avoided.