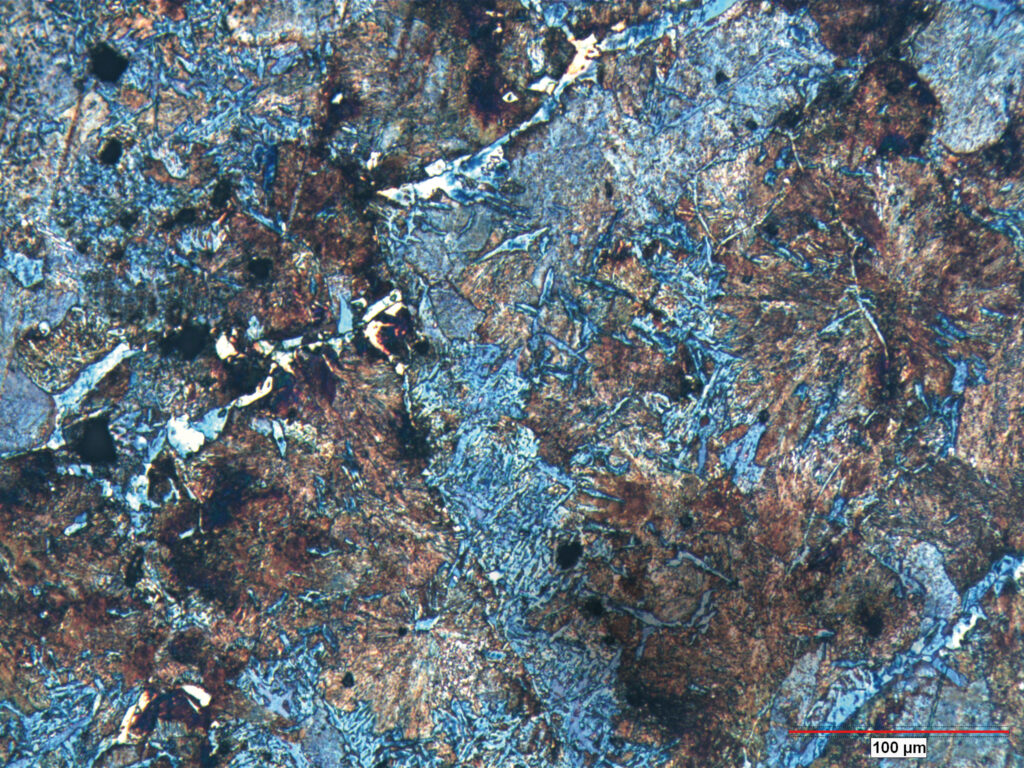

The photograph shown on the back page of this magazine is an example of a high-strength low-alloy (HLSA) steel with 0.23% C, 1.50% Mn and 0.05 % Ti that was produced under laboratory conditions. Using an optical microscope, the photograph was taken of a sample that was etched in two steps: step 1 with structure etching using the Vilella method, and step 2 with color etching using the modified Lichtenegger and Bloech method. The objective of this special etching procedure was to achieve a clearly visible contrast of the acicular ferrite in the steel microstructure in order to apply image-analysis software to automatically determine the acicular ferrite fraction.

What is acicular ferrite?

Acicular ferrite is a needle-shaped ferrite modification that nucleates intragranularly between the austenite grains on non-metallic inclusions, thereby creating an interwoven, chaotic microstructure with outstanding toughness properties. Because of its excellent toughness, steel manufacturers have increasingly focused their attention on acicular ferritic steels over the past few years. The factors contributing to the formation of acicular ferrites are not yet entirely understood, which is why more detailed investigations are of great importance for the industrial application of these materials. The Chair of Ferrous Metallurgy at the Montanuniversität Leoben has been investigating acicular ferrites since 2012 in the scope of the FWF (Förderung der wissenschaftlichen Forschung) project TRP 266-N19. Research activities have led to the development of a computer-aided method of analyzing the acicular ferrite content which, when compared to the former manual measurement method, results in a significant reduction in personnel effort and expense as well as improved objectivity.

Turning a disadvantage into a benefit

For a long time, non-metallic inclusions were considered a negative material constituent of steel. A new field of research was created in the 1990s that focuses on oxides metallurgy (first described in 1990 by J. Takamura and S. Mizoguchi). This research area involves the targeted modification of non-metallic inclusions in order to use them to influence metallic microstructures, for example, as nucleation sites for the formation of acicular ferrite. Thus, non-metallic inclusions can contribute to the optimization of material properties.

Because ultraclean steel with an extremely low inclusion content is now produced by steel manufacturers, a further reduction of inclusions is hardly possible. In such cases, oxides metallurgy (also referred to as inclusion metallurgy) presents an opportunity to put any remaining inclusions still contained in the steel to positive use. This is why inclusion metallurgy (and thus acicular ferrite) has a highly promising future potential to improve steelmaking.