This post is also available in: 简体中文 (Chinese (Simplified))

Melt Expert is the solution of choice from Primetals Technologies to monitor and control the melting process of electric arc furnaces. It retrieves information from a vast array of components, and uses this data to conduct a real time analysis of the current state of the melting process. Melt Expert continuously regulates the furnace parameters with the highest degree of reliability, and displays all relevant data by means of an easy-to-use interface. The application of the sophisticated algorithms of Melt Expert helps to save energy and results in many other substantial benefits.

Melt Expert is one of the most essential tools Primetals Technologies has to offer for steel plants that are based on electric arc furnaces. It is a sophisticated control system that regulates the position of the electrodes so that they will always operate with an optimal arc length. Additionally and importantly, the system provides detailed information about the furnace and makes its findings easily accessible. It employs characteristics of “Industry 4.0” technology, meaning that it systematically accumulates and evaluates large amounts of data that stem from the processes taking place in and around the electric arc furnace. Melt Expert then does its calculations, makes adjustments to the furnace parameters, and presents all data through an easy-to-understand interface.

Universal accessibility

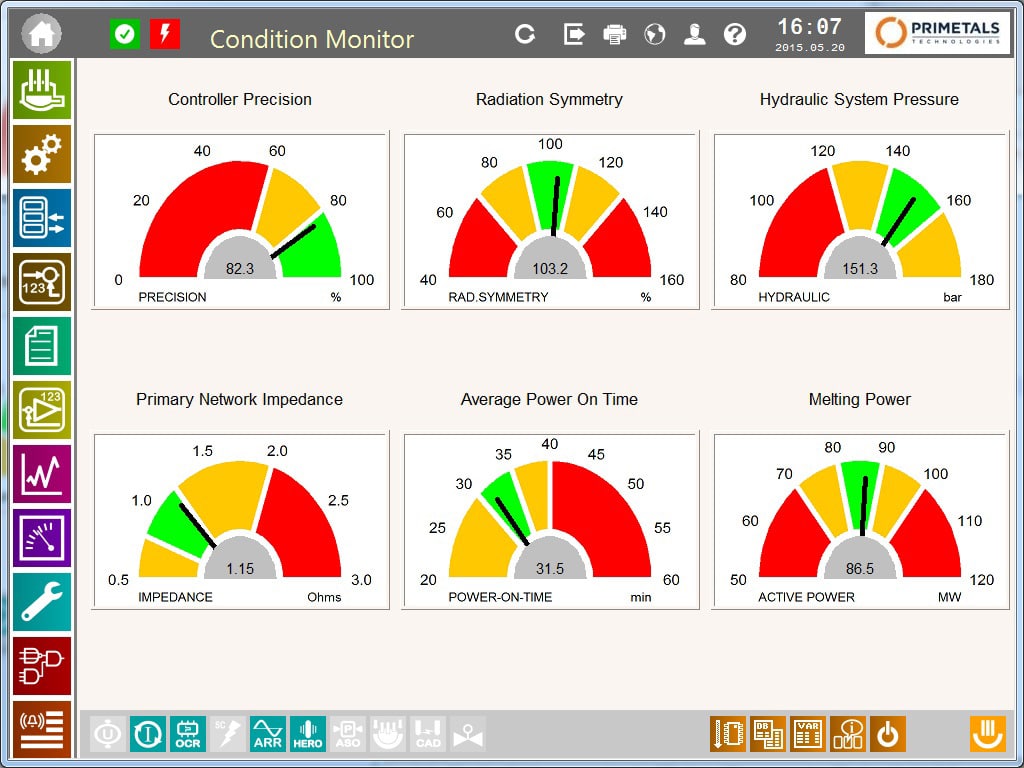

The user-friendly interface is indeed one of the important strengths of Melt Expert. It is both highly detailed and evenly structured, allowing for a streamlined evaluation process of all ongoing furnace activities. This is essential because it ensures that the personnel in charge of maintaining proper furnace operation can quickly identify the functions they require for a given task. All information displays are clearly labeled, and the interface follows intuitive design principles.

The engineers at Primetals Technologies who developed the Melt Expert technology are particularly proud of the smartphone app that they recently finalized. It is scheduled for release in the spring of 2017. With this app, all of the essential information that Melt Expert collects and evaluates is immediately accessible, utilizing the touchscreen of your smartphone to display data and collect user input. It has certainly never been more straightforward to monitor an electric arc furnace.

Innovation, backed by experience

Work by the development team took about three years to design, test and prove Melt Expert technology in its current form. However, it is also true that the underlying components are the results of decades of research, and are based on two highly successful predecessor solutions: Melt Expert combines the benefits of both the Arcos and Simelt electrode control systems, and bundles all of their respective features into one comprehensive control package.

The fact that Melt Expert makes use of the rich technological legacy of Primetals Technologies has several positive effects. One of them is that it is relatively easy to upgrade an existing Arcos or Simelt installation to an up-to-date Melt Expert system. The requirements will, of course, vary from plant to plant, but the compatibility with older equipment is generally very high. Another positive aspect is that the core components of Melt Expert and the underlying technological concepts are extremely well-tested and refined. Arcos originated in 1991, and Simelt was first introduced in 1980. Together, the two have acquired an impressive reference base of approximately 500 EAF and ladle furnace installations.

Constant monitoring and analysis

So what exactly does Melt Expert do? The system communicates with all equipment connected to the electric arc furnace. Thereby, it acquires substantial amounts of data about the ongoing melting process and the relevant support procedures. It then analyzes and interprets the acquired information and passes on its findings to superordinate systems of the furnace. This guarantees an optimal adjustment of the furnace electrodes, and is the basis for a multitude of benefits reaching from energy savings to an extension of the electrode lifespans.

The core idea is that Melt Expert acts like a “point of service” for both humans and machines, meaning that it functions as an information hub and a guidance center that indicates what the necessary course of action should be. This is true especially in scenarios where the furnace is operating in a less-than-optimal mode or is steering into potential problems. Melt Expert proactively helps to prevent accidents and ensures that any plant-shutdown times due to unforeseen occurrences are avoided. Also, unnecessary wear of furnace components is averted. For instance, Melt Expert can reduce electrode consumption by about 3%.

MAIN BENEFTIS

- State-of-the-art furnace control

- Increased furnace reliability

- Reduced energy consumption

- Highly developed safety functions

- Reduced need for maintenance

- Integrated system checks

- Universally accessible interface

- KPI and benchmark reporting

Preventive maintenance

The electrode control system not only acts as an instruction system and as an information server, but also offers special services for maintenance purposes. In this role, Melt Expert makes use of very unique design aspects to fulfill the requirements of the maintenance crew, assisting them in the examination of the condition of the electrical and mechanical systems during maintenance shutdowns. Fully automatic diagnostic tests of the equipment can detect faults in high current busbars, hydraulic valves and pumps, current and voltage levels, and the rolls of the electrode-lifting column. Detailed reports show the results of all measured parameters, including evaluations and specific advice for repair measures that should be taken. This reduces the need for human interpretation of the readings. Even in scenarios where Melt Expert itself is not in charge of making any major decisions, it supports the superordinate systems by providing well-founded recommendations. Interactions with surrounding facilities enable further optimization of the system.

Higher efficiency and reliability

Melt Expert introduces several key benefits. Besides the longer lifetime of the furnace electrodes, energy savings of about 2% can be expected. Due to the more precise furnace-control possibilities, the power-on and shutdown times can be kept 3% shorter. This increases overall productivity. The sophisticated Melt Expert algorithms drastically improve operational stability and make the melting process much more transparent. The system reduces the need for maintenance considerably, and increases the long-term reliability of the furnace through integrated system health checks.

Furnace control made easy

A key benefit that should not be underestimated is that the Melt Expert system itself does not require any maintenance. Its dependability, as well as its ease of use and high efficiency, originates from the decades of experience that Primetals Technologies has gained from the earlier Arcos and Simelt furnace control solutions. With Melt Expert, users get the most competent electrode control system on the market: It is the one with the highest effectiveness, the one with the best user interface, and, particularly when put into historical context, certainly the one that has proven its reliability in hundreds of installations.

Melt Expert unites many different sources of information, which results in numerous very tangible advantages – and a few additional ones that usually remain in the background but are just as important.

The system interface provides simple and fast access to all process-relevant data, and includes benchmark reporting (e.g., power- on time, energy input, active power input, flicker, arc stability and heating rate). It can be used to compare new readings with historical ones, offering users an even better idea of the current state of the steelmaking process. Since the interface is accessible through a variety of devices, including smartphones, keeping an eye on furnace activity could not be more simple.

Equally relevant are the less obvious preventive maintenance functions. Melt Expert permanently monitors many hydraulic, mechanical and electrical components, and conducts a real-time analysis based on these readings. Additional long-term analyses ensure that creeping malfunctions are identified early on. Melt Expert also registers less than-optimal furnace operation due to short electrodes and manual intervention. Automatic self-diagnostic checks, an early-stage alarm system, and built-in suggestions ensure that unplanned downtimes can be proactively avoided.