Primetals Technologies’ condition monitoring for processing lines uses predictive-maintenance algorithms to pinpoint incidents before they occur. The condition monitoring system (CMS) is part of the newly developed Through-Process Optimization solution (TPO) of Primetals Technologies.

TPO encompasses the intelligent Through-Process Quality Control (one of the company’s “Industry 4.0” IT systems), Through-Process Know-How (the vast application knowledge that optimally tunes the IT system to customer requirements), and the Total Condition Optimizer (Expert System for processing lines). Each of these tools is designed to enable customers of Primetals Technologies to tackle new market challenges: to develop new products, improve product quality, and increase the overall competitiveness of their production lines.

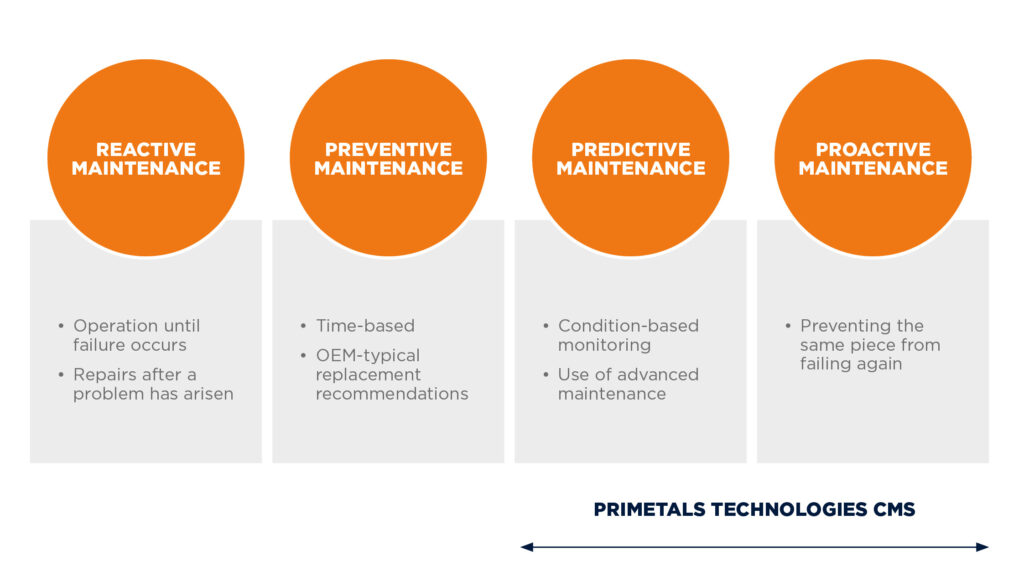

The CMS focuses on predictive and proactive maintenance with the aim of increasing line reliability while decreasing operating costs. Without the CMS, maintenance has to be either corrective (reactive maintenance) or systematic (preventive maintenance). The downside to reactive maintenance is that it requires an unscheduled stop of the line, resulting in a drop in line availability and production losses. On the other hand, preventive maintenance can sometimes be carried out too early and therefore involves unnecessary costs. The CMS, meanwhile, is the ultimate approach for predictive conditional maintenance; maintenance is performed “on time,” thereby optimizing the lifetime of each component by avoiding any unscheduled stoppage and anticipating component end–of-life.

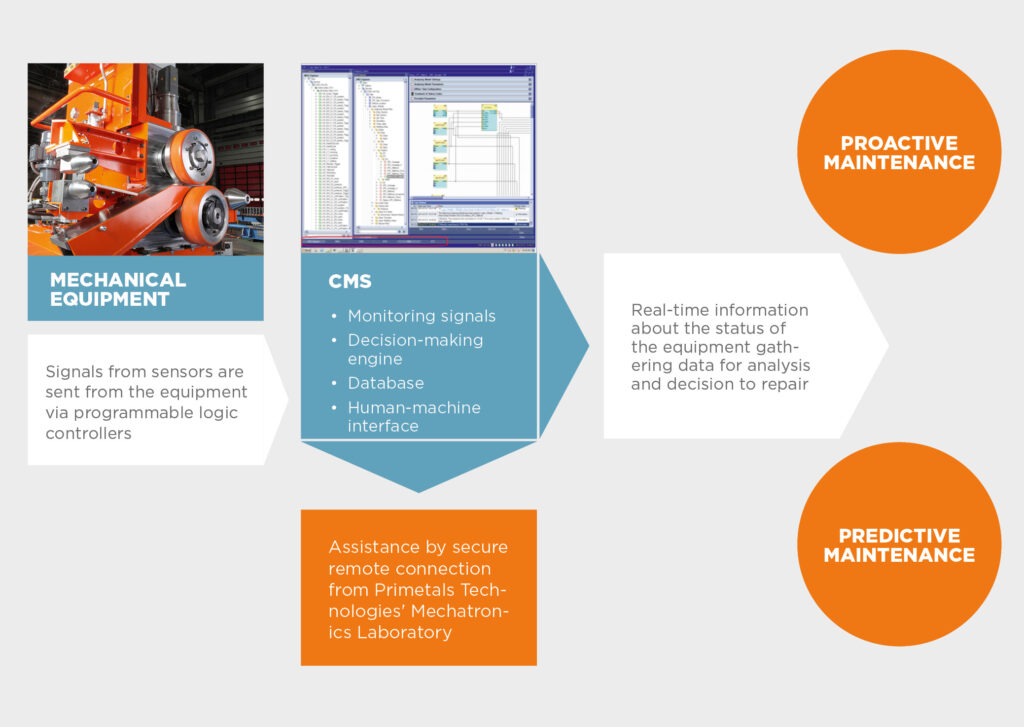

For the processing-line equipment built by Primetals Technologies, the company’s French-based Mechatronics team is responsible for developing, configuring, and commissioning the CMS. The team comprises mechanical, electrical, automation, IT, and process specialists whose expertise can be called upon remotely via the “CMS Remote Hotline.” Customers can use the hotline to help them better diagnose a problem through “proactive maintenance,” but Primetals Technologies experts can also train customers and help them to develop new rules in the CMS installed on their production lines.

CMS for the side trimmer

These days, most of the equipment supplied by Primetals Technologies includes a CMS module. This also applies to the side trimmer, which comprises several key components—hydraulic, pneumatic, servo motors, and knives—all individually monitored by the CMS.

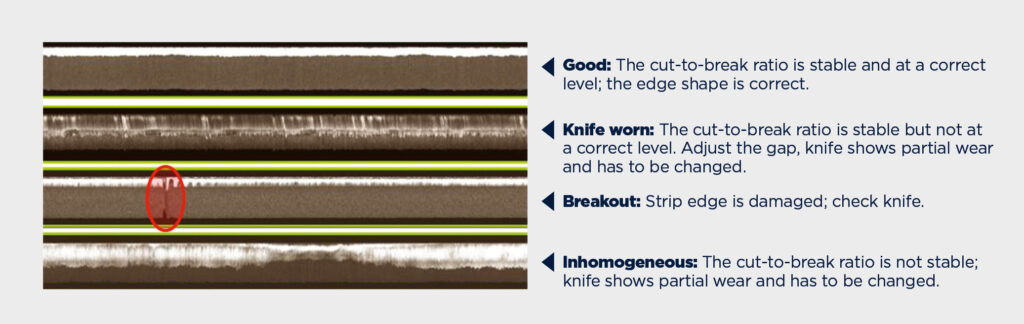

There is particular emphasis on the condition of the knives, which directly affects the edge quality of the sheet and, indirectly, other areas such as the operating speed of the motors and the consumption of electrical energy. In the worst case, the sub-optimal condition of the knives could even damage downstream equipment. With previous maintenance strategies, knives have to be changed according to the length of strip cut in kilometers. This presented two main drawbacks: knives were often changed too early (while still operational and in good condition) or too late (after product deviations occurred). Now, however, the CMS uses specific cameras to inspect the edges and analyze the picture obtained in order to qualify edge quality, detect any wear or breakout, and also swiftly warn operators that a change of the knife is necessary.

Vibration-analysis based monitoring

Any machine in operation produces a degree of vibration generated by its movements, which can be rotary or linear. Small levels of ambient vibration are perfectly acceptable, whereas high and increasing levels of vibration are symptomatic of an anomaly and have to be prevented. Vibrations are largely a result of the centrifugal forces acting on rotating machine parts, and can come from a misalignment of machine-drive trains, bearing damage, gear defect, imbalance, and other causes.

The CMS analyzes vibrations using feedback from special piezoelectric sensors installed on certain parts of the equipment. These sensors look for vibrations on different axes. By correlating the dominant frequencies with different elements of the equipment, the CMS is able to determine the origin of the vibration.

Edge monitoring system

The EdgeMon edge monitoring system typically consists of four cameras mounted on the rotating turrets of the side trimmer to the left and right of the steel strip. In this setup, two cameras are installed on each side of the side trimmer. One of them is actively used while the other remains in maintenance position. The sensors of EdgeMon are directly mounted on the shear block. Triggering of the camera for knife breakout detection is done with either a rotary encoder on the shaft of the knives or with the plant-speed signal. This trigger has to be provided by the supplier of the side trimmer. EdgeMon monitors and visualizes the trimmed edges, and evaluates the cut-to-break ratio—a typical quality parameter for trimmed edges. Furthermore, knife breakouts can be detected automatically based on periodic analysis. Typical detection reliability, based on figures from different plants, is about 90%. For other more unusual defects that are not detected automatically, visualization helps the operator to recognize them immediately.

Propertymon measuring system

PropertyMon is a quality-monitoring system for the online detection of mechanical and magnetic properties of the steel strip for various types of processing lines. Measurable steel grades are hot- and cold-rolled ferromagnetic steel strips including micro-alloyed, interstitial-free, dual-phase, and transformation-induced plasticity steels. The system performs continuous and contact-free inspection over the entire strip length based on an electromagnetic measurement principle. All values are immediately available and stored in PropertyMon’s internal database.

The EdgeMon system monitors and visualizes the trimmed edges of the steel strip. It evaluates the cut-to-break ratio and conducts regular analyses to detect any knife breakouts. The detection rate achieved by EdgeMon is high, with about 90% of all identified problems found automatically.

The Mechatronics Lab in Montbrison

Process or maintenance optimization does not happen overnight; as every steel producer knows, improvements are usually time-consuming. It takes significant and relentless effort to be a market leader that continually improves equipment quality, develops new products, and minimizes production downtime. Primetals Technologies is fully aware of this fact and supports its customers for the entire lifecycle of their equipment. For this purpose, the company has installed a multi-disciplinary, highly skilled team in a brand new Mechatronics laboratory at its French facility. The team is involved in the design, development, commissioning, and optimization of processing line equipment, and is always available to swiftly assist customers around the world.

Customer-oriented solutions

Customers will often benefit greatly from a quick yet highly professional analysis of their equipment and a solution-oriented discussion with an experienced Primetals Technologies specialist. This is why remote access for fast and easy-to-obtain support is now available for all solutions supplied by Primetals Technologies. This has become possible thanks to the recent forays in digitalization and “Industry 4.0”-type technologies, which Primetals Technologies has chosen to thoroughly embrace to optimally serve its customers.